4 min read

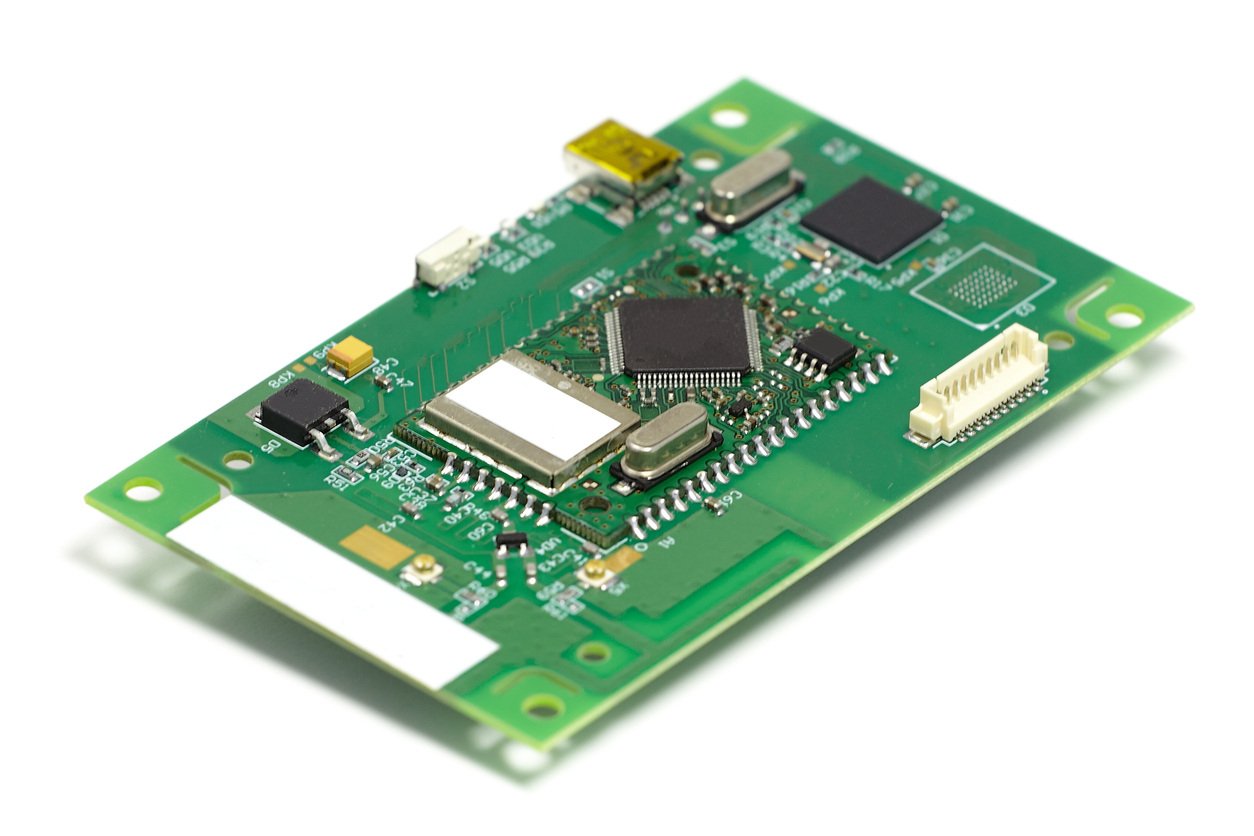

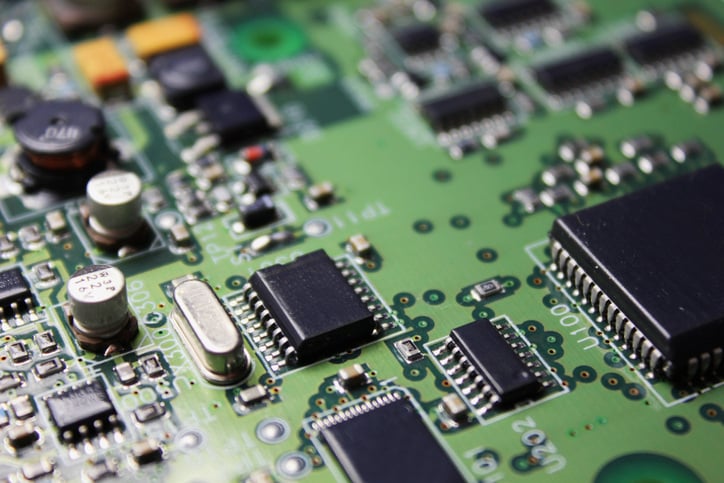

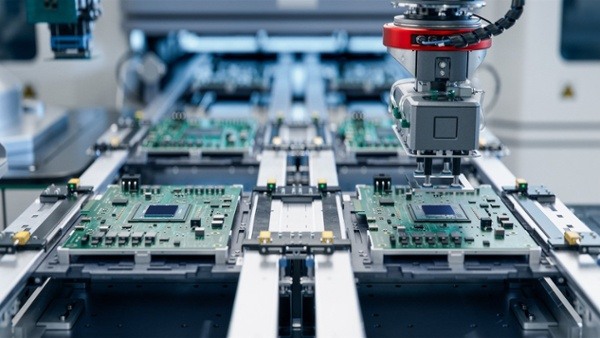

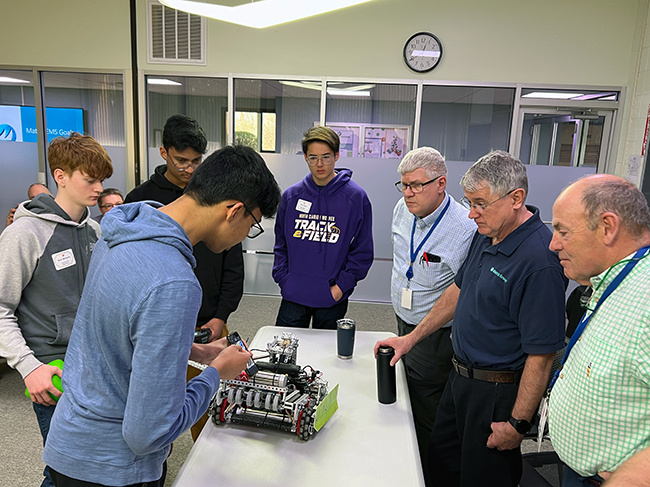

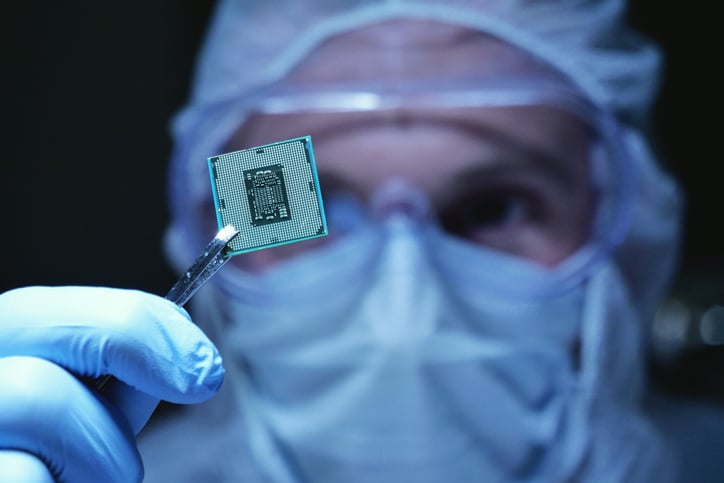

Electronic Component Shortages: 2025 Outlook

Electronic component shortages didn’t fade away in 2024 – and they’re still making life complicated in 2025. Lead times have improved since the worst delays a few years ago, but pricing swings and sourcing headaches are still very real. Chips are...

Read More

.jpg?width=788&height=443&name=iStock-1373244125%20(2).jpg)