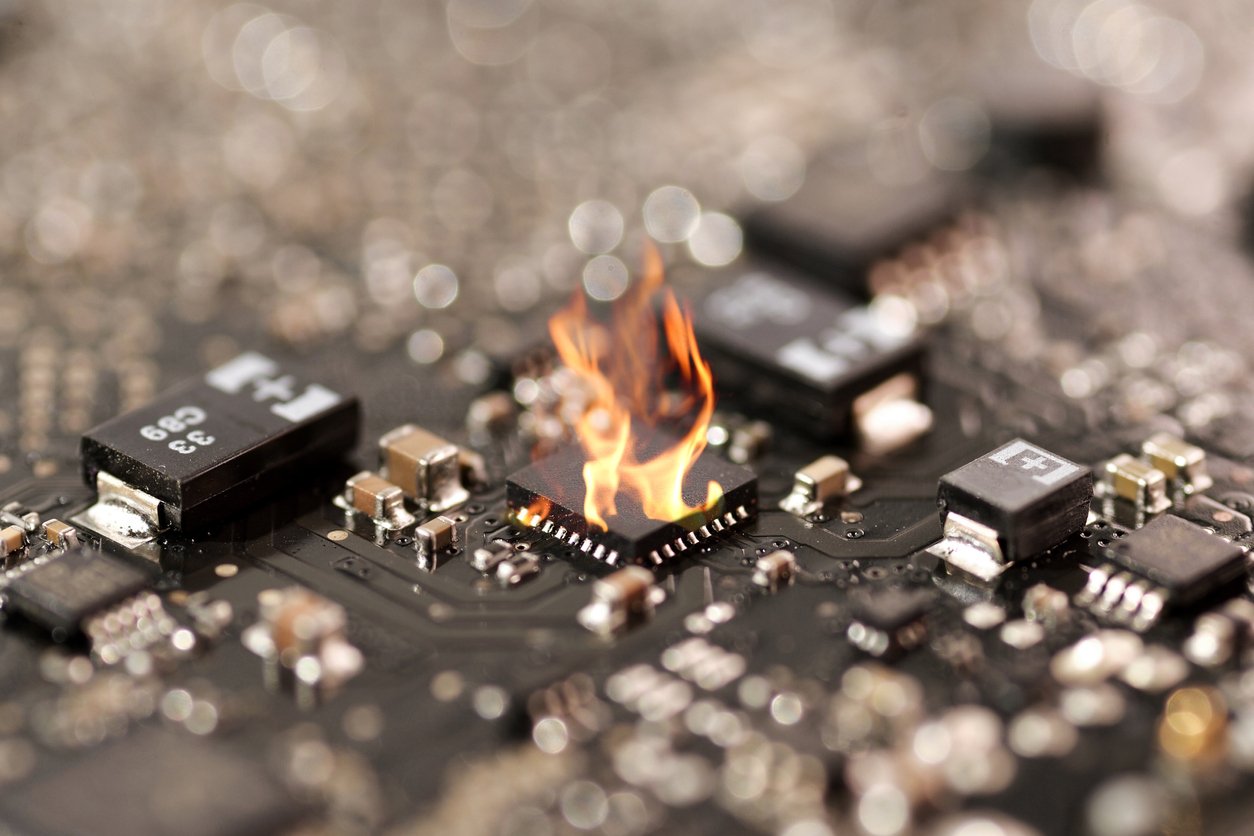

Common PCB Defects: What Causes a Circuit Board to Burn?

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...

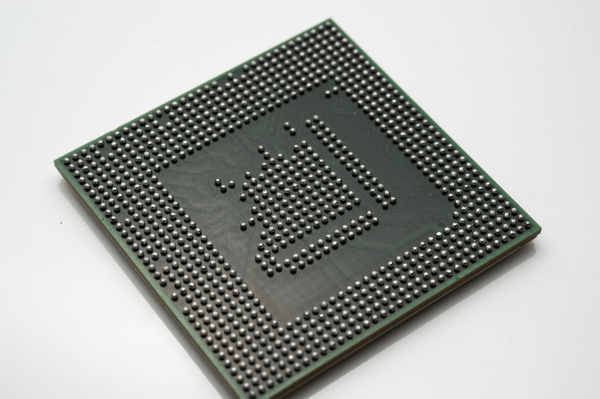

Ball grid arrays are a form of high-density, low-cost packaging in the PCB industry.

Ball grid arrays are a form of high-density, low-cost packaging in the PCB industry.

BGAs, as they’re called, use the underside of the chip for connection to the board. This is in contrast to conventional chips, which utilize perimeter connections. This change results in more space for connection, increasing the performance of the PCB.

Other benefits of a ball grid array include:

Let’s take part each benefit piece by piece, plus look at the features of each type of BGA:

ball grid arrays are a newer technology, using tiny spheres of solder to form a connection instead of conventional wire pins. As a result, there are several advantages to using BGAs, making them one of the more popular options in today’s marketplace.

Some of the advantages include:

The silicon chip of a BGA has less thermal resistance than its quad flat package brethren. This results in faster heat dissipation from the integrated circuit to the PCB.

Thanks to the connections on the bottom of the chip, they are shorter. This means faster speeds and higher performance.

Pins in a quad flat package are typically very thin and more fragile. Thus, damaged and bent pins are commonplace. When this damage occurs, repair is nearly impossible.

The solder pad connections of a BGA don’t run the same risk, giving you a more reliable connection.

There are three types of BGAs:

Each type has its benefits and detriments. Knowing the strengths of each is critical to maximizing the performance of a PCB.

With the connections hidden beneath the chip, ball grid arrays typically enlist X-ray inspection to examine the board quality. It’s the only way to detect defects such as:

As for rework, once a BGA is removed from a board, it can never be reused.

If you outsource your engineering or manufacturing to another company, be sure they have experience in BGA work. It’s worth the switch if you’re not already using BGA packaging.

Contract electronic manufacturers with years of experience in BGA design can help use them to optimize your circuit board in a cost-effective manner.

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...

Working with small circuit board areas can increase the risk of various PCB defects, tombstoning in particular. While the grim nature of “tombstone”...

As young people enter the workforce, it is important to develop and possess certain qualities in order to be successful. Employers expect individuals...