3 min read

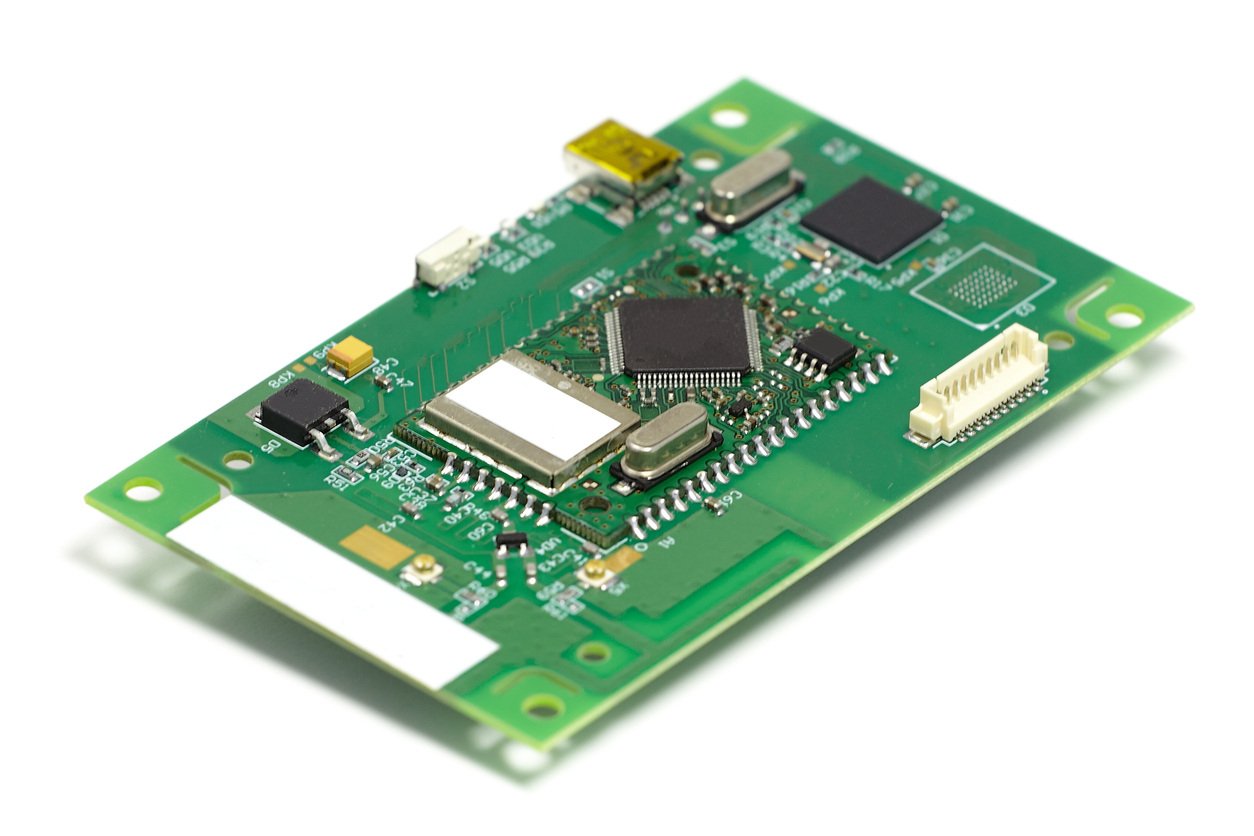

Industrial PCB Repair, Remanufacture, or Redesign? How to Decide

OEMs often rely on electronic products and systems that remain in service for many years. Over time, however, these systems can become increasingly difficult and expensive to maintain.

Read More

.jpg?width=788&height=443&name=iStock-1373244125%20(2).jpg)