Creating Custom Printed Circuit Boards: Is Your Volume Worth It?

So, you’ve made the choice to design a custom PCB for your design. Instead of buying off the shelf electronics.. but what’s next?

Tests for printed circuit boards (PCBs) come in many varieties based on cost, breadth, time, and other factors. There are many ways to test your PCB, but in-circuit testing, known as ICT, is the most advanced and accurate method.

An in-circuit test, also known colloquially as ICT testing and bed of nails testing, is used to:

To perform the test, the engineer lays the PCB atop a specially designed bed of nails, where needles make direct connections to the circuit board. This method does not harm any of the other components connected to the PCB.

Some of the components that an ICT can measure include

The goal of an ICT is to get to almost 100% coverage of the PCB, which might not always be possible. However, an ICT does detect problems with power shorts, grounds, and discrete components, which is far more comprehensive than other methods of testing.

ICT testing is accurate and often necessary to protect the life and functionality of your equipment, but it can sometimes be costly. Here’s a breakdown of the reasons why.

PCB in-circuit testing pricing generally starts at $10,000 and can reach upward of $50,000. The average cost is about $20,000.

Several factors go into what ICT testing costs, including:

It’s logical to assume that testing one PCB is going to cost less than testing a warehouse full of them. That said, if you are testing 20 identical PCBs, it’ll cost you less than if you’re testing 20 different PCBs.

ICT is the preferred method of PCB testing for manufacturers that need a high volume of production.

PCBs come in all shapes and sizes, from the common 2x2” board to the 17x20” board. Since a custom bed of nails is necessary for each unique PCB that needs an ICT, size certainly has a part to play.

A smaller PCB means a smaller bed of nails, resulting in lower fixture costs.

The more complex your PCB is, the more an ICT will cost. In-circuit testing equipment has varying levels of compatibility depending on the contractor; for reference, Matric’s is compatible with boards that have up to 1,296 nodes. As with size, the more complex the board, the more complex the bed of nails needs to be.

Compared to other PCB tests, the ICT test is by far the fastest. A functional test averages 20-30 minutes per board and a flying probe test can take anywhere from 3-15 minutes.

The ICT test usually takes less than 1 minute. Depending on panel design and spacing of the boards, more than one PCB can be tested at the same time.

That being said, manufacturing downtime is very small. But, it’s still important to plan accordingly and account for any unforeseen circumstances to decrease idle time.

One reason electronics companies shy away from ICT testing is the initial cost of developing the bed of nails equipment. The fixture-building process might take anywhere from 4-6 weeks, depending on the complexity of your design.

Yet, ICT testing is a comprehensive PCB exam that reduces the need for maintenance and repairs. Testing is consistent, and about 85-90% of the process is completely free from the possibility of human error.

While the initial investment into ICT testing is a potential downside, in the long run, it will eradicate the need for most other testing methods and significantly reduce cost of incidental repairs.

ICT testing is the most in-depth and advanced method of testing PCBs, hands down.

The up-front cost for fixture creation is certainly worth the long-term benefits:

Again, the price of ICT testing is dependent on the volume, size, and complexity of your PCBs. And while ICT is certainly a great way to test the functionality of your PCBs, it’s not the only way.

If you have any questions about in-circuit testing and want more information about alternatives, check out the free e-book below.

So, you’ve made the choice to design a custom PCB for your design. Instead of buying off the shelf electronics.. but what’s next?

PCB (printed circuit board) costs are a concern for any electronics designers or manufacturers -- both the materials that go into PCBs and the...

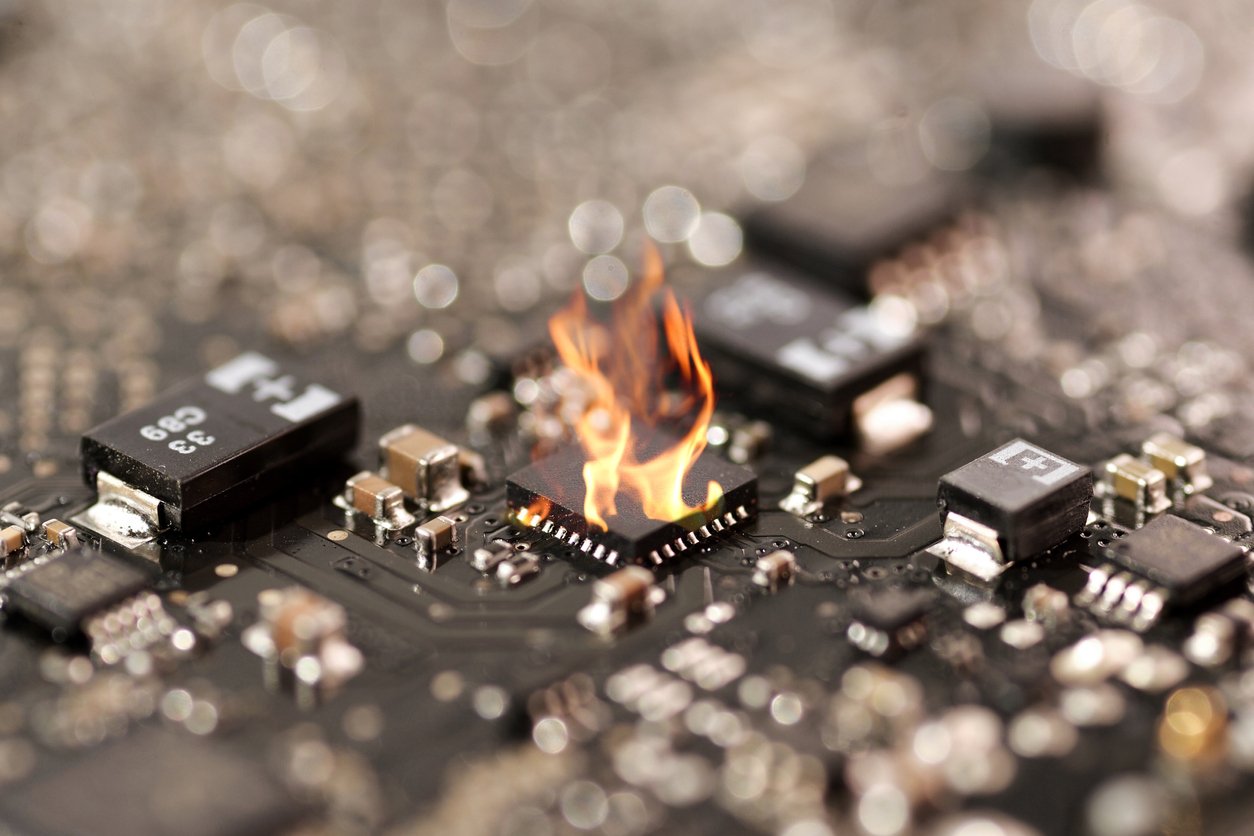

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...