Why Partner with an Electronics Contract Manufacturing Company?

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

Consolidating services is a great way to reduce costs, lead times, & confusion. Unfortunately, most electronics contract manufacturers (ECMs) don’t offer services throughout all stages of the development process.

Since Matric and Dynamic do — from design to production to repair — we wanted to explain the capabilities of an all-in-one electronic manufacturing services company. Keep reading and you'll find that ECMs can handle more in-house than you realize!

Electronics manufacturing services are offered by companies that design, test, build, deliver, or provide aftermarket electronic parts and assembly services. The size and scope of those services depend on whom you work with — for example, we specialize in high-mix, low-to-mid-volume assemblies.

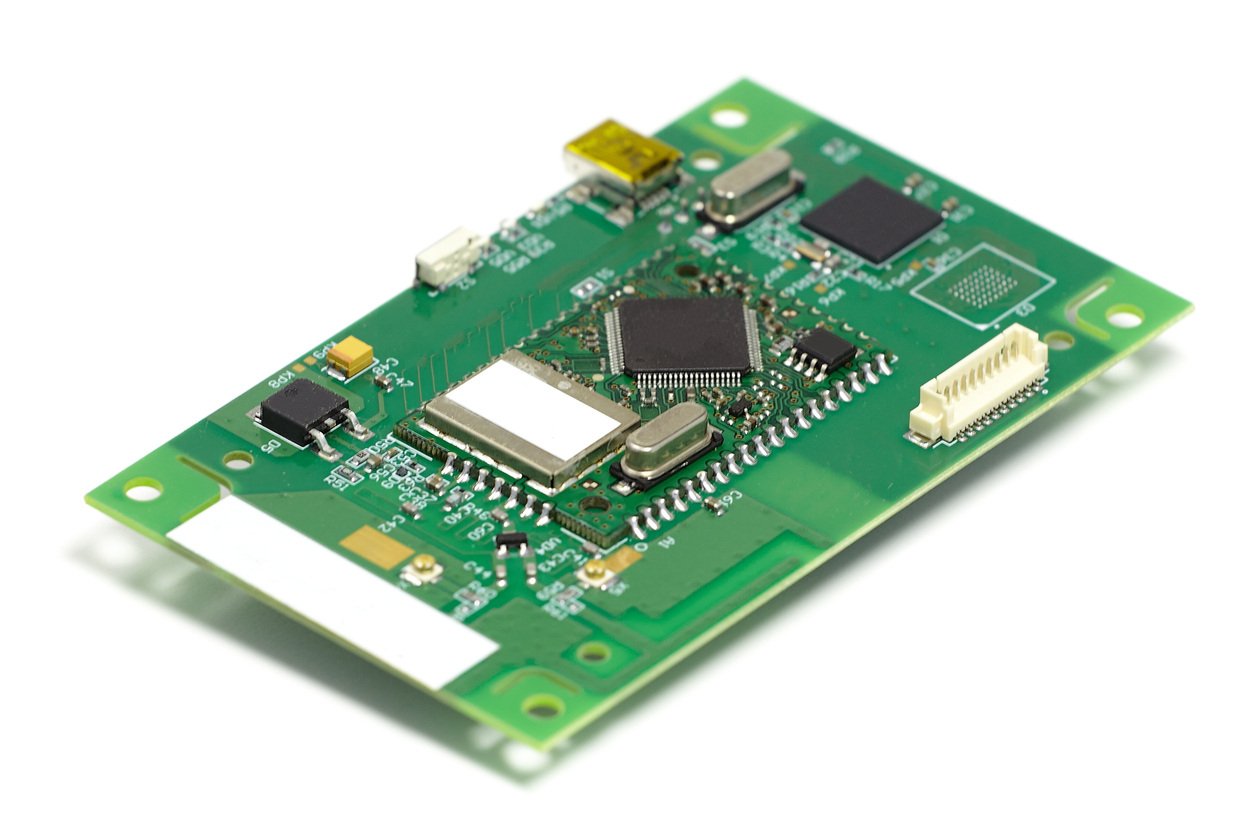

There are two ways to put a printed circuit board (PCB) together — through-hole and surface mount technology (SMT). Because we’ve used surface mount since the late 1980s, we can take your aging through-hole product and convert it to a more modern SMT design. This is possible thanks to state-of-the-art machinery that’s improved both speed and accuracy. Again, not every SMT PCB assembly supplier can do this, so research before you send a quote.

A few of these deserve further explanation.

Here are the specific capabilities Matric Group (Matric + Dynamic) works with:

No matter the order volume or complexity, your ECM should aggressively pursue a goal of zero defects. Matric Group uses a wide variety of PCB testing methods to monitor quality, including:

Electronic design services should turn your product concept into a reality, no matter the complexity. The experience and skill of your PCB design company should be on display from initial discussions through final product validation.

All products need to be well-built, often attractive, and sometimes both. Matric Group routinely develops custom housings in conjunction with PCB form factors. We’ll advise you on the ideal material, whether it’s stainless steel, aluminum, or injection-molded plastic.

OEMs should expect support with product development that meets ISO 9001, ISO 13485, and AS 9100 standards. Matric Group will do that while also validating your product through recognized industry standards

Custom cable and mechanical assembly can also be a one-stop experience.

Specializing in harsh environment cables, Matric crafts reliable cables for mining, medical, instrumentation, and other fields.

With a certified quality management system, your contract electronics manufacturer should be able to engineer, test, and produce quality cable assemblies ranging from micro push-pull connectors to harnesses and complex mechanical subassemblies.

Your ECM’s commitment to customer satisfaction must continue long after product delivery.

Check for three qualities in an electronics aftermarket services provider: experience, expertise, and technology. For example, Matric Group keeps the customer’s supply chain going with product upgrades, calibration, and repair services handled by state-of-the-art equipment run by skilled technicians.

Regardless of where your industrial or consumer was made or what it was made for, your electronics manufacturing services provider should have the know-how to service it properly.

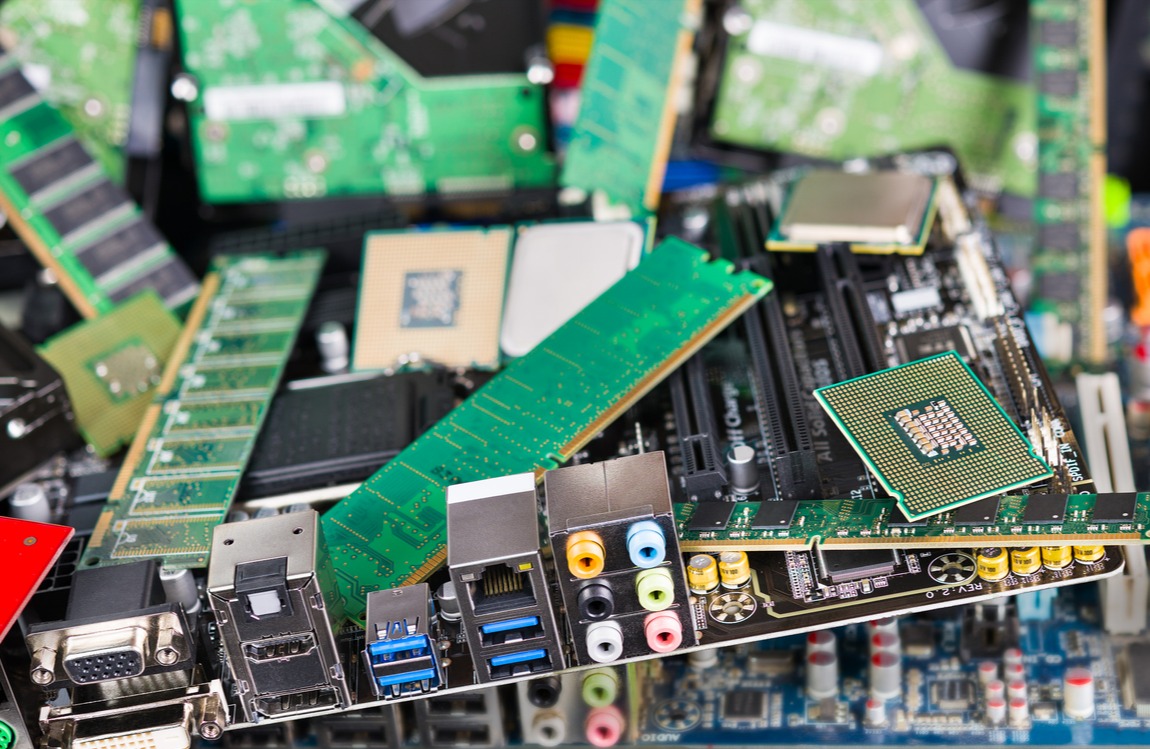

Losing a critical component at the wrong time can make life very hard for OEM teams trying to get a product to market.

Fortunately, your ECM can employ several tools, strategies, and services your ECM can employ to take the burden of electronics obsolescence management off your shoulders.

The best way to succeed with forecasting is to ensure the customer/supplier communication channel is always open.

Talk to your ECM about what’s coming up. It should orchestrate the last-time buy and NCNR (noncancelable, nonreturnable) orders you need to keep the supply chain well-oiled.

It’s hard to be mindful of your stock when so much else is going on at the office.

Offload your inventory management headache to an ECM. Component inventory management makes sure you’re not stuck with unpopulated boards you can’t fill, or with boards, you have to redo from scratch.

Work with an electronics manufacturer that treats your case as unique.

When the right ECM handles your lifecycle management, you’ll get:

Nobody expects you to have your bill of materials memorized. That’s why we work with SiliconExpert to organize all component manufacturer data into a single, regularly updated program.

Anytime a component’s on life support, you’ll get a quick alert.

Click here for an in-depth explanation of obsolescence management.

Surprised by how much the right electronics contract manufacturer can do? Don’t be — there are reasons the best electronics manufacturers offer all-in-one services:

If you’d like to learn more about what turnkey PCB manufacturing is all about, click the graphic below.

(Editor's note: This blog was originally published in October 2019 and was updated in August 2022 to reflect current information.)

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

There’s a certain need for speed in manufacturing circuit boards -- the electronics industry demands it, and your end users demand it. But how quick...

Plastic waste may snag all of the headlines, but it's not the only type of waste overwhelming landfills and contaminating soil and water.