SMD PCB Sensors: The Backbone of Mine Safety & Efficiency

Mining operations today rely heavily on precise, real-time data to ensure safety and efficiency. Printed circuit board (PCB) sensors have become...

An electric vehicle battery management system (BMS) is essential to keeping an EV running safely and reliably. It helps protect the battery and maintain performance by monitoring key conditions and controlling how the battery charges and discharges. When a BMS malfunctions, it can lead to serious problems for the vehicle and for driver and passenger safety.

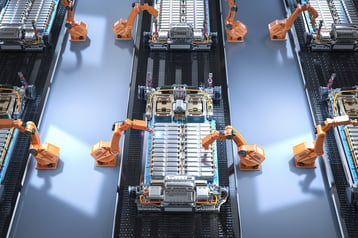

Printed circuit boards (PCBs) are a core part of the system. They house critical components like sensors and controllers and provide the connections that allow everything to work together. By linking these parts, PCBs enable smooth communication across the system and support optimal overall performance.

The BMS monitors and maintains each cell of an EV’s battery pack. It provides real-time feedback on key metrics, including:

The system also helps protect the battery cells from overcharging, discharging too quickly, or starting the thermal runaway process.

The key functions of a BMS include:

By accurately monitoring and controlling all aspects of a battery pack’s performance, a BMS can extend its lifespan significantly while ensuring safe and reliable ride EV operation. With advances in technology like artificial intelligence (AI) and machine learning (ML), future BMS systems will be even more effective at managing batteries for maximum performance over time.

As electric vehicles become increasingly more popular, so does the demand for more efficient and reliable sources of energy. The development and implementation of sustainable & safe batteries are critical to ensure that electric vehicles have access to reliable, clean power sources.

Sustainable batteries are designed to be more efficient and last longer. Additionally, they can be made using renewable materials, allowing them to help reduce emissions associated with transportation. However, concerns remain, including the thermal management of electric vehicle battery systems.

Sustainable batteries are designed to be more efficient and last longer. Additionally, they can be made using renewable materials, allowing them to help reduce emissions associated with transportation. However, concerns remain, including the thermal management of electric vehicle battery systems.

As the demand for sustainable battery technology continues to grow, companies are investing heavily in research and development to make newer and more advanced types of batteries available.

With the demand for optimized battery management systems and energy control in the EV, higher performance is expected. Flexible PCBs meet this, as they are smaller and can fit in tight spaces.

Flexible PCBs must be:

The electronics world, in general, increasingly demands more power fit into a smaller case, which is the same for EVs. As a result, flexible PCB design must be adaptable and easily improved as new technological advances are made. Therefore, the search for the right PCB is a constant one.

PCB integration can be tricky. Temperatures can leave the PCB vulnerable: high temperatures mean the potential to warp, while low temperatures mean condensation buildup is possible. Pests and dust can cause significant damage to a stored PCB.

Errors in manufacturing can also be a significant concern. The failure to insulate two metal traces on a high-voltage board can mean an arc that destroys the entire circuit. Repairing an issue of this level can require a return visit to the factory where it was manufactured - creating a risk of downtime for your production line.

Society’s focus on sustainability and efforts to move away from fossil fuels puts pressure on the EV industry. That is nothing, however, compared to the various challenges that have plagued the industry to this point.

Six of the main barriers to adoption the EV industry still faces include:

Cell equalization helps to operate at maximum efficiency. It involves charging and discharging each cell in a battery pack separately so that all cells are balanced in terms of charge level and overall voltage. Cell equalization enables a longer lifespan for batteries by reducing the amount of energy lost due to unbalanced cells. It also decreases the likelihood of reduced range or slower charging times.

Thanks to advancements in technology related to the BMS and improved algorithms for balancing cells, electric vehicle owners see

This success has made it possible for automakers to offer increasingly competitive models with bigger batteries than ever before.

Despite these successes, there are still challenges related to cell equalization which need to be addressed. One issue, however, is cost – BMS systems are expensive components, and integrating them into vehicles can pose a significant financial challenge for automakers.

Additionally, not all battery technologies currently support efficient cell equalization techniques; this means that some EVs may be unable to fully benefit from these improvements in technology. A new battery management system testing method must be implemented regularly to help identify and adjust for EVs that do not support the technology.

Finally, while improved algorithms are making cell equalization more efficient than ever before, they also require extremely precise measurements, which can be difficult to achieve across different vehicles and manufacturers consistently.

Have questions about our design and assembly? Consider downloading this resource:

Cell degradation occurs over time as a battery is used, and its capacity gradually decreases.

Cell degradation can be caused by high temperatures, high currents, deep discharges, or frequent recharging cycles. As cell degradation increases due to these factors, so does the amount of time required for a full charge. This decreases the range of an electric vehicle’s battery over time. One way to minimize cell degradation is to avoid exposing your battery to high temperatures and excessive current draw for extended periods of time.

Aging is the natural loss of energy storage capacity that occurs as lithium ions move from the cathode to the anode materials during charging and discharging cycles.

Aging can be countered by using a battery management system (BMS). The BMS monitors and identifies cells that reach end-of-life prematurely, thus enabling replacement on a more efficient timeline. The PCB allows the BMS to do so by providing the technology to optimize performance and extend battery range.

When it comes to data storage, one of the biggest successes has been the development of lithium-ion battery technology capable of storing large amounts of energy. This technology has allowed for a longer range and improved performance out of electric vehicles as compared to other types of vehicles.

However, there are still some challenges that the electric vehicle industry faces regarding data storage, including:

While the electric vehicle industry has made great strides in improving data storage solutions, much work still needs to be done to make them more effective and cost-efficient. As technology continues to advance at a rapid rate, these issues will likely continue to be worked on until better solutions are available for all types of customers.

The electric vehicle industry has seen notable successes in terms of managing battery capacity. However, the limited battery life of some electric vehicles can make it difficult for customers to make long journeys without having to periodically stop and recharge.

New charging methods, such as battery swapping systems, have been developed to allow customers to quickly charge their cars without needing to wait for a full recharge. Despite this progress, coordinating different charging needs across multiple systems can be tricky and require careful management in order to ensure smooth operation.

The electric vehicle industry has made significant progress in recent years and has seen widespread adoption around the world. However, with increased production and use of electric vehicles, there have been certain challenges to safety that have emerged. Here are some of the successes and challenges that the electric vehicle industry has faced and is currently facing in regard to safety:

EV battery management systems have come a long way as real-world challenges have been identified and solved. As electric vehicle adoption grows, BMS technology will need to keep advancing to meet higher expectations for safety, performance, and reliability. At the same time, PCB manufacturing will need to evolve alongside it by supporting more precise monitoring, smarter controls, and stronger system communication.

Running into issues in your PCB manufacturing process? Use this PCB testing resource to spot problems faster, reduce risk, and launch with confidence.

Mining operations today rely heavily on precise, real-time data to ensure safety and efficiency. Printed circuit board (PCB) sensors have become...

In every facet of modern life, we're surrounded by electronic devices, all of which are powered by printed circuit boards (PCBs). With so many...

Printed circuit boards (PCBs) have been instrumental in the rapid advancement of technology since their introduction in the 1940s. PCBs...