What OEMs Can Do About Obsolete Electronic Parts

Losing a key component at the wrong time can be downright terrifying to OEM teams trying to get a product out. So what can an OEM do about obsolete...

3 min read

Matric Group

:

Jul 11, 2018

Matric Group

:

Jul 11, 2018

Perhaps the most groan-inducing aspect of electronics manufacturing is component sourcing. Limited availability, dubious component quality, and conflict mineral laws are common causes of you and your manufacturer’s headaches when it comes to sourcing parts.

Fortunately, programs exist that reduce the hassle of this experience, in turn lowering risk in your supply chain. The program of choice at Matric Group is SiliconExpert, and in this article I’ll tell you why your ECM (electronics contract manufacturer) should be using this program -- and how it makes an OEM’s life easier.

SiliconExpert functions as a database of over 250 million components from thousands of suppliers, including:

This database allows you to search for parts and access vital information like obsolescence forecasts, environmental compliance, and inventory data. In short, it’s a one-stop shop for vital component information.

With a few clicks, an ECM can identify a part’s RoHS (Restriction of Hazardous Substances) lead-free status, whether it contains conflict minerals, and its current lifecycle stage. This helps identify which supplier to purchase from and allows ECMs to understand future availability of parts and plan accordingly.

Other functions of this software include the ability to cross-reference and compare parts side-by-side from over 12,000 manufacturers, making sure you’re getting a high-quality part in a timely manner.

Many of us have dealt with obsolete parts and the problems they create, and one of the most effective ways of avoiding this roadblock is forecasting. SiliconExpert allows you to keep a keen eye on part obsolescence with its advanced life cycle algorithms. These give you or your contract manufacturer a heads up as to when a part is approaching end-of-life -- allowing you enough time to plan accordingly.

Think of your Bill of Material as a map of your assembly. SiliconExpert would then function as the compass, allowing you to navigate your BOM with ease.

Simply upload your BOM to scrub and validate any old or incorrect data and run reports to receive new insights into your design. You can also sign up to receive emails when there’s PCN, Datasheet and life cycle updates for parts in your BOM. When you’re done, export your data to an Excel, .csv or .xml file with ease.

Another useful tool offered by SiliconExpert is Quote Manager. This allows an ECM to manage its sales quotes by combining internal pricing and inventory data with SiliconExpert’s database.

By utilizing a quoting system directly integrated with a parts database, ECMs can easily multi-source parts and speed up their quoting turnaround times.

Sure, Google is a fantastic tool for scouring the internet for any and all information related to a specific thing. The problem with using Google or other horizontal search engines when it comes to parts sourcing is it casts too wide a net. Your team will find themselves spending hours sifting through material to find the necessary information that is otherwise provided directly to you with vertical search engines.

Third-party software is considered a vertical search engine, meaning it brings you a focused group of results that pertain only to what you are searching for. This makes it much easier to find the best option available from thousands of suppliers in a quick and easy fashion. One search of a part number will give you:

This is all information you’d have to search for individually on Google to find, and the information there could be less reliable or even outdated.

By utilizing vertical search, your electronics contract manufacturer is saving time on the sourcing aspect of your assembly and can focus more on production and quality, a win-win for both sides.

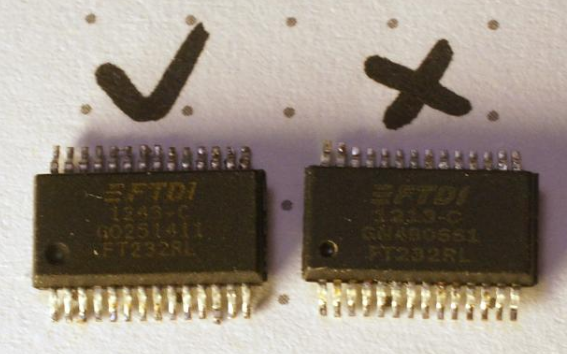

Counterfeit parts are a real problem in the electronics industry. This particularly comes into play with obsolete parts.

In 2013, 89% of counterfeit parts were mirroring obsolete parts, leading many ECMs to reach for these fake parts when desperate for last use components.

If you aren’t using a software like SiliconExpert that helps you identify counterfeit components before purchase, you could have a tough time deciphering between what’s real and fake.

In the end, electronic component database software is as valuable to an ECM’s business as any other piece of its equipment. When in talks with a new ECM, go over what their sourcing strategy looks like, and ask if they use SiliconExpert or a viable alternative. It will make everything that follows just a little bit easier.

Click below to learn more about the importance of obsolescence management and other aftermarket services your ECM should be offering:

Losing a key component at the wrong time can be downright terrifying to OEM teams trying to get a product out. So what can an OEM do about obsolete...

One of the biggest concerns of electronic manufacturing is the reliability of the components being used. Counterfeit electronic components have long...

Understanding your marketing is key to a successful product run. That applies not only to your customers, but their home country as well.