‘Intrinsically Safe’ Design Guidelines for Electrical Devices

When turned on, electrical equipment generates sparks. Some equipment generates heat that can lead to ignition, while electric arcing occurs between...

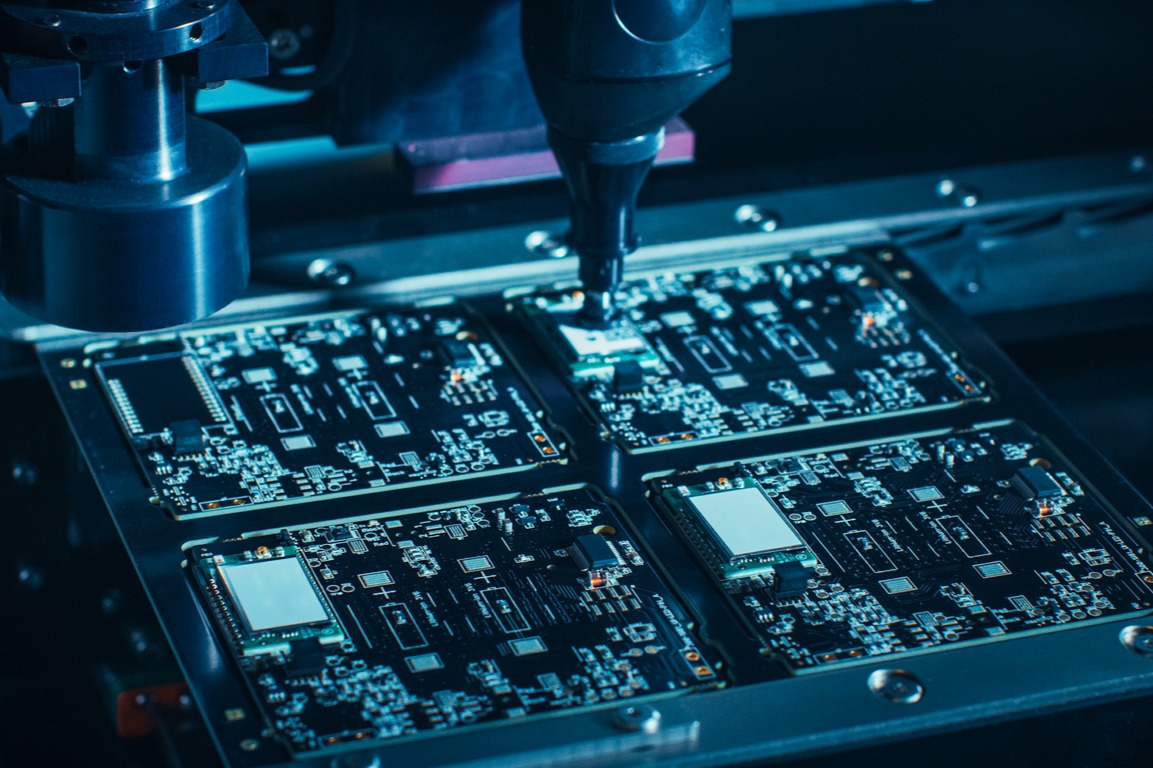

In the constantly evolving world of technology, safety remains a top concern among engineers during development. Whether it’s a sensor in your car, your son’s handheld video game, or a surgically implanted medical device in your elderly neighbor, we need assurance that our products are intrinsically safe (IS) during use.

This is especially true with electronics used in already dangerous conditions. Atmospheres in mines, chemical plants, processing mills, tankers, and oil refineries can contain extremely hazardous areas that rely on intrinsically safe equipment to keep workers from harm’s way.

Intrinsically safe electronics limit the electrical or thermal energy available for ignition, allowing for safe operation in hazardous areas. Common industrial equipment like motor brushes and switches are at risk of:

This equipment protects workers from threats by simplifying the circuitry, controlling internal temperatures, and adjusting components to reduce dust-caused shorts.

Fundamentally, intrinsic safety is a low-energy technique where the current, voltage, and power are reduced to a level too low to cause ignition. Generally, the maximum power level available is less than 1.3W.

Additionally, the maximum temperature must be controlled, and among the six classes used to define temperature levels, electronics meeting the T4 designation are considered IS. This is because, at this level, temperatures won’t exceed 135 degrees C (275 degrees F).

Many electronics can be found in intrinsically safe forms. These include:

Why is intrinsically safe equipment important in these products? Simply put, lives depend on it.

Communications inside a mine are integral to the safety of the workers, and failure of those lines could result in an accident. Electronics used in environments producing flammable gases like hydrogen and propane cannot have a risk of sparking or overheating, or an explosion is imminent.

Our obsolescence guide can help you find the right engineering solution:

Explosion-proof products are capable of containing an explosion inside an enclosure. It will keep flames or hot gases from escaping the housing. The term "explosion-proof" does not indicate the product is capable of withstanding a strong external force.

Intrinsically safe electronics receive their classification because they are low-power enough that they won't cause an explosion in the first place.

Besides the inherent safety benefits of meeting intrinsically safe requirements for electronics, there are other upsides to consider when deciding what you need out of your product:

While individual parts can be IS-certified, the entire system must be designed to be intrinsically safe. It requires full documentation of all components and wiring used in the system.

Immediately following installation, an inspection will take place, followed by periodic inspections throughout the life of the equipment. This is to identify any damage, deterioration, or unapproved replacement of IS components.

While IS equipment can in some cases serve as a replacement for explosion-proof equipment, that is not always the case. This is due to the reliance on low power and temperatures.

For more on keeping electronics running properly and safely for your target market, get our Guide for Testing Capabilities below:

(Editor's Note: This article was originally published in March 2018 and was updated in July 2023 to reflect current information.)

When turned on, electrical equipment generates sparks. Some equipment generates heat that can lead to ignition, while electric arcing occurs between...

Just about any piece of electronics can be dangerous when they’re manufactured poorly. But when you’re manufacturing for the mining industry, you’re...

When reliable performance matters – whether in medical devices or handheld mining tools – every component in your design needs to contribute to...