Specs for Class 2 Electronic Product Design

When introducing a new electronic product design, many OEMs don’t fully understand the differences between IPC classifications -- or understand them...

3 min read

Matric Group

:

May 16, 2019

Matric Group

:

May 16, 2019

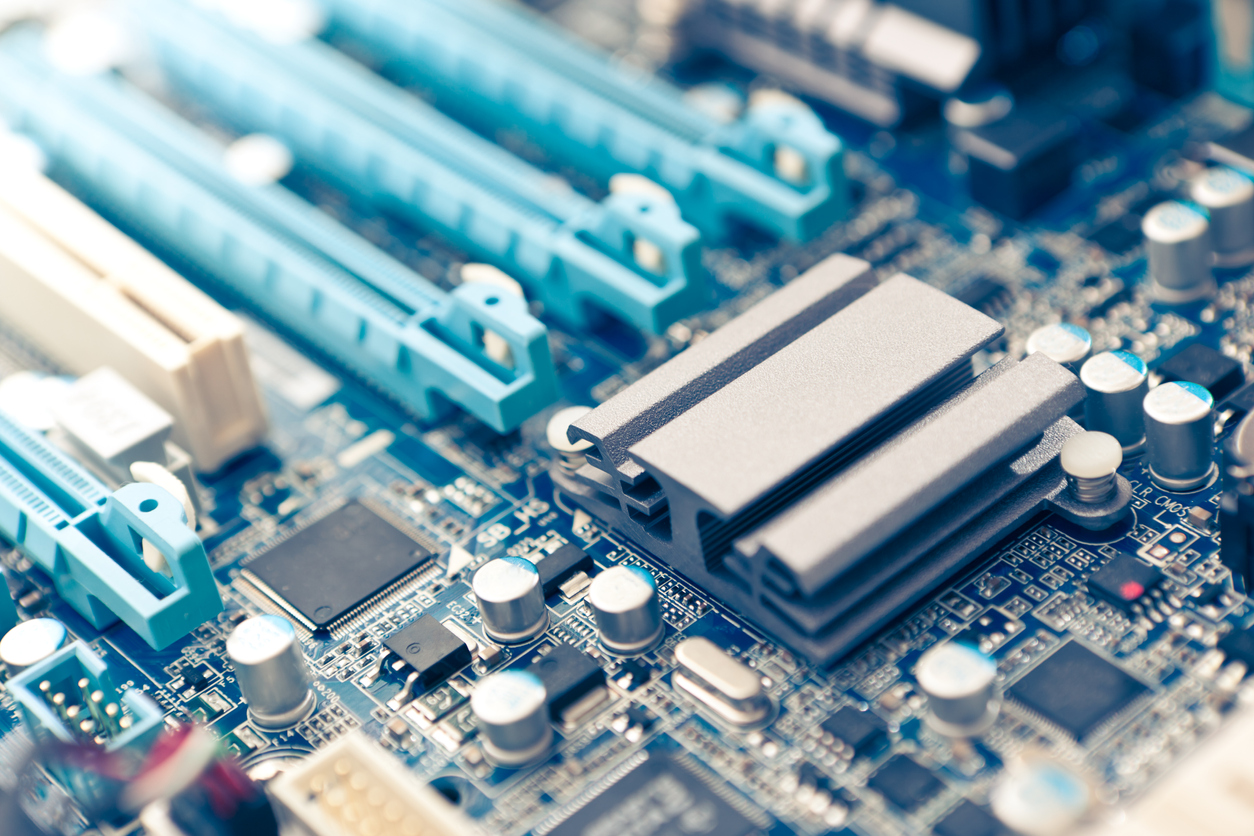

If you’re considering switching an existing electronic product design from through-hole technology to surface mount technology (SMT), you’ll want to do your homework first.

If you’re considering switching an existing electronic product design from through-hole technology to surface mount technology (SMT), you’ll want to do your homework first.

SMT versions of through-hole PCB designs are available in most cases -- and there is no shortage of advantages of surface mount technology. However, failure to account for typical challenges in transitioning to SMT can lead to costly hurdles.

The following steps are meant to serve as a checklist of sorts for your transition. Once you check your boxes, you can move forward with confidence and make informed choices.

When you look at surface mount vs. through-hole, you will see there are many advantages of surface mount technology, including:

However, there are a few reasons why you might want to stick with through-hole, including:

Keep in mind that some components may need to remain through-hole even if you do transition to SMT for durability and power.

There are a few things you should keep in mind with your PCB development plan to minimize issues with regulatory certifications:

Reputable electronics design companies should be able to redesign most boards, but make sure it’s possible to convert your specific product. Questions you should ask include:

Every company is different -- you may or may not have the capacity to handle quite a bit of the design yourself. Keep in mind the benefits of contracting with electronics design companies that have engineering capabilities.

You’ll avoid communication issues and avoid overengineering with the new product team. Plus, everything will stay at the scale and volume you’re looking for.

Does your product need to be backward-compatible with existing equipment in the field? Your electronics contract manufacturer can give you options concerning compatibility, but ultimately it’s up to your upper-level management.

Backward compatibility costs more, but the increased customer satisfaction may make it worthwhile.

A contractor with capable electronics manufacturing design services can support your redesign. It can quote the scope of the work and ask you the right questions -- like those in this list -- to determine the optimal PCB design and how much it will cost.

Determine the number of PCB prototypes you’ll need and what types of PCB testing you’ll require. Understand your prototype run and how to design for manufacturability to avoid:

The electronics contract manufacturer should understand life cycle management so it’s not designing with obsolete or end-of-life components. The contractor should use parts that have a good outlook in terms of life span.

You don’t want to spend all this time redesigning the part only to produce something that’s nearing obsolescence before it comes off the line.

If you have questions about transitioning a PCB assembly from through-hole to surface mount technology -- or anything about electronics product PCB design in general -- let us know. We advise OEMs on the entire PCB production process from design to packaging, so nothing you ask will scare us!

When introducing a new electronic product design, many OEMs don’t fully understand the differences between IPC classifications -- or understand them...

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

Most often, the foundation, or base, of a printed circuit board (PCB) consists of a substrate and laminate. Different PCB laminate and substrate...