4 Times When a Quick-Turn PCB Board House Isn't Enough

There’s a certain need for speed in manufacturing circuit boards -- the electronics industry demands it, and your end users demand it. But how quick...

3 min read

Matric Group

:

Mar 07, 2025

Matric Group

:

Mar 07, 2025

Product lifecycle management (PLM) is an important strategy companies can use to optimize product development and reduce downtime. By anticipating product obsolescence and working with your PCB manufacturer early in the process, product designers can order more efficiently while ensuring product availability over time.

Companies should also regularly review product inventory levels to ensure a sufficient supply of products to meet customer demand. Companies can avoid costly product shortages or stockouts by proactively managing product inventory and product phase-out plans.

Another key product lifecycle management best practice is monitoring product performance. Companies should track product sales to:

Let’s review the possible causes of your electronic product life cycle sputtering out prematurely. Then we’ll explore how you and your contractor can proactively protect your product line and expand its lifetime.

Market decline is the final stage in the industrial electronic product lifecycle. This is where obsolescence and other external factors influence product sales and future investment. There are four potential influencing factors related to the market decline period – all of which can be overridden by product lifecycle management.

Market decline has four potential components:

One of the best practices for product lifecycle management is to anticipate product obsolescence and plan accordingly. Companies should continuously:

These will help ensure product availability over time and prevent potential losses due to product unavailability.

A damaged image due to product failure or recalls can significantly impact sales for that line and every other product or service you offer. Companies should prioritize product lifecycle management to reduce the impacts of a damaged product image and maintain customer loyalty.

One way companies can reduce the impacts of product image damage is by quickly identifying product issues. The benefit of quick identification is both an immediate response to customers and the ability to take corrective measures. Communicating product updates to customers will help maintain customer trust and loyalty, and protect the product's reputation.

One hurdle that is hard to predict but occurs all too often in a product’s life cycle is the decline of demand as a product is surpassed by a better option. To reduce the risk of this situation, companies must focus on:

One hurdle that is hard to predict but occurs all too often in a product’s life cycle is the decline of demand as a product is surpassed by a better option. To reduce the risk of this situation, companies must focus on:

companies can reduce the impact of waning product viability by taking proactive measures to keep electronic designs current and product inventory at appropriate levels.

Pro Tip: Check Out These Other Obsolescence Resources:

Do Your ECM's Obsolescence Management Procedures Look Like This?

Mitigating Component Obsolescence in Medical Devices

Having a product reach obsolescence is less than ideal because implementing a viable replacement product design can take years. For that reason, IT departments prioritize forecasting, planning, and anticipation of:

In the case of technology, plan for the fix before the break. Developing a relationship with a trusted PCB manufacturer in the concept stage ensures electronic product obsolescence is addressed promptly.

By establishing consistent communication, product designers can stay up-to-date on the latest trends, materials, and technologies to update design quickly. Turnkey PCB manufacturers can also provide product designers with product lifecycle management best practices and information regarding phase-out plans, inventory levels, and recalls.

PLM is a great strategy for many electronics OEMs with complex supply chains. However, there are certain situations where PLM is not the most effective solution.

One scenario is when product designs are already obsolete and product redesigns will take too long to be effective. In this case, product designers should focus on phase-out plans and inventory levels while looking to the next new idea.

Product designers should consider the individual situation before investing resources into extending an electronic product’s lifetime.

By following product lifecycle management best practices such as anticipating product obsolescence, monitoring product performance, and proper inventory management, companies can:

The obsolescence of electronic products is a complex subject, but it is important for productivity. To learn more, check out this free resource:

There’s a certain need for speed in manufacturing circuit boards -- the electronics industry demands it, and your end users demand it. But how quick...

Global supply chain shortages mixed with bottlenecks in the shipping industry and labor shortages have triggered serious problems in nearly every...

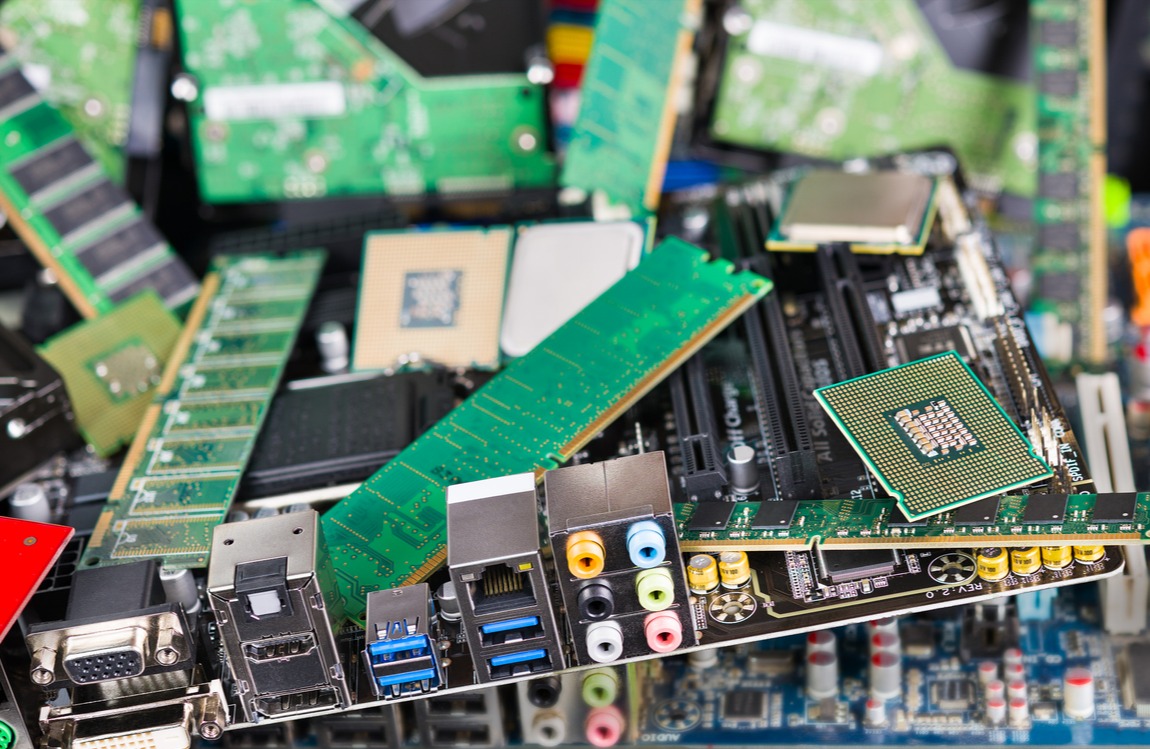

Plastic waste may snag all of the headlines, but it's not the only type of waste overwhelming landfills and contaminating soil and water.