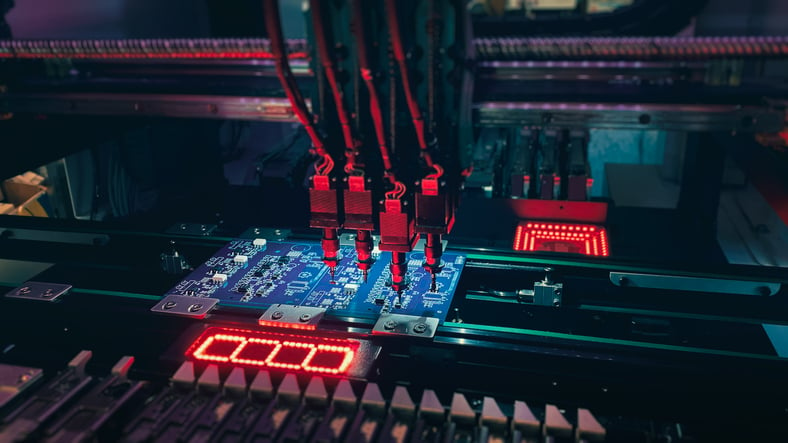

What Is SMT Assembly?

As today’s electronics designs become smaller and more complex, more engineers are relying on surface mount technology. After the 1980s, this...

When building the next generation of electronic products, the last thing you want is to be sidelined by production issues, faulty boards, or unanticipated shipping delays.

Every day you spend sorting out supply chain chaos or dealing with quality problems is time and money lost — along with your competitive edge.

Partnering with an American PCB manufacturer offers the reliable performance, seamless communication, and peace of mind you need to bring your innovations to life — without the headaches. With stringent quality standards, shorter lead times, and intellectual property protection, a U.S.-based partner can streamline your production process and help you deliver better products faster.

Here are 9 reasons why partnering with an American PCB supplier is more than a smart decision — it’s a strategic advantage for your business:

Partnering with an American PCB manufacturer offers numerous benefits beyond basic production. From stringent quality standards and shorter lead times to enhanced communication and robust IP protection, each advantage provides a unique edge for your business.

Let’s explore the nine key reasons why choosing a U.S.-based PCB supplier can elevate your production process and deliver long-term value:

American PCB manufacturers must adhere to strict quality standards, such as IPC-6012 for rigid boards and IPC-6013 for flexible boards. These standards ensure that every PCB produced meets the highest levels of quality and reliability, minimizing the risk of defects and enhancing product performance. Most U.S. manufacturers invest in advanced testing methodologies, including automated optical inspection and in-circuit testing, to maintain stringent quality control.

Furthermore, many American manufacturers have in-house quality assurance teams that conduct thorough inspections at each production stage. This meticulous QA process significantly reduces errors, making U.S. PCB manufacturers ideal for industries that demand high precision and reliability, such as aerospace, automotive, and medical devices.

Resource Ensure Quality & Safety with PCB TestingWhen high costs and customer safety are involved, effective PCB testing and prototyping are crucial. Close collaboration between OEMs and manufacturers ensures optimal results. This e-book provides strategies and insights for seamless testing and inspection. Download here:

|

American-made PCBs offer a significant advantage in turnaround times, outperforming many overseas manufacturers. This rapid delivery allows businesses to accelerate project completion and meet tight deadlines.

American PCB manufacturers can more effectively respond to customer requirements and changes due to their on-site presence in the United States. This proximity enables quick adjustments and problem-solving, ensuring projects stay on track.

Superior quality also contributes to efficient supply chain management for American-made PCBs. Local sourcing of components and parts reduces lead times and lowers costs. Additionally, the accessibility of customer service and technical support further enhances the overall experience, providing peace of mind and minimal disruptions.

Effective communication is crucial in any manufacturing partnership, and working with an American PCB manufacturer provides a distinct advantage in this area. Local time zones, language compatibility, and the ability to meet in person facilitate better collaboration. These factors enable you to address design challenges, troubleshoot issues, and receive real-time feedback more efficiently.

American manufacturers also bring a wealth of technical expertise to the table. Many have extensive experience working across diverse industries and can provide insights that optimize design for manufacturability and functionality. This collaborative approach often results in higher-quality products and a smoother production process.

Local PCB manufacturing offers multiple environmental and cost-saving benefits. By reducing the distance that products need to be transported, carbon emissions are significantly lowered. U.S.-based manufacturers also comply with strict environmental regulations, supporting sustainable practices and recycling initiatives that help minimize waste and reduce plastic pollution in landfills.

Additionally, domestic production cuts transportation costs and can result in competitive pricing for locally manufactured products. These savings enable businesses to offer more competitive deals, consider additional product features, and enhance customer satisfaction, ultimately creating new business opportunities.

Resource: Simplifying Electronics Regulatory Compliance and StandardsStruggling with electronics regulatory compliance or standards? We’ve simplified everything for you in the Electronics Manufacturing Compliance & Standards Guide. Get all the answers and clarity you need in one comprehensive resource! Download here: |

Partnering with American PCB manufacturers directly supports domestic employment and strengthens local economies. These partnerships not only create jobs but also stimulate investment in the community, fostering economic growth and development.

By supporting American manufacturers, businesses contribute to national innovation and technological advancement. Access to cutting-edge equipment, materials, and expertise ensures high-quality products that meet regulatory standards and remain competitive in today's market.

American PCB manufacturers often possess specialized expertise and years of experience, setting them apart from international competitors. Their in-depth knowledge and support can help businesses navigate complex manufacturing processes with ease.

By collaborating with American PCB manufacturers, businesses can leverage a wide range of services to drive success. These services include:

The expertise and insight offered by American manufacturers can identify and address potential issues proactively, ensuring a smoother production process and improved outcomes.

Recent global events, such as the COVID-19 pandemic and ongoing geopolitical tensions, have highlighted the vulnerabilities in global supply chains. Working with an American PCB manufacturer reduces your dependency on overseas suppliers, mitigating risks associated with international trade, such as tariffs, shipping delays, and regulatory changes.

Domestic sourcing ensures greater control over supply chain variables, providing a more stable flow of critical components. This reliability is essential for industries that cannot afford disruptions, like healthcare, telecommunications, and automotive. By partnering with a U.S.-based supplier, you can maintain consistent production schedules and avoid costly delays.

One of the biggest concerns when outsourcing PCB manufacturing is the risk of intellectual property theft. Working with an American PCB manufacturer significantly mitigates this risk due to the country’s robust IP protection laws. U.S. manufacturers are legally bound to safeguard sensitive designs and proprietary technologies throughout the production process.

This level of security is often not guaranteed when working with manufacturers in regions with less stringent IP laws. By choosing a domestic partner, you ensure that your innovations remain protected, preserving your competitive advantage.

American PCB manufacturers are known for their ability to provide customized solutions tailored to specific project requirements. Whether it’s a complex multi-layer board or integrating advanced technologies like surface-mount technology or through-hole assembly, U.S. manufacturers can accommodate various needs.

This flexibility fosters innovation, enabling companies to experiment with new materials, explore different design approaches, and integrate emerging technologies. The result is a more dynamic development process and products that are optimized for both performance and manufacturability.

The U.S. government has taken several steps to bolster the domestic electronics manufacturing industry through legislation such as the CHIPS and Science Act. These initiatives provide various incentives and funding opportunities for American PCB manufacturers, allowing them to invest in cutting-edge technology, expand production capacity, and improve supply chain resilience.

For businesses seeking long-term partnerships, these government-backed initiatives ensure that American manufacturers will continue to lead in technology and innovation, providing a solid foundation for growth and development.

Partnering with an American PCB manufacturer offers numerous advantages, from superior quality standards and shorter lead times to enhanced communication and robust IP protection.

By choosing a U.S.-based supplier, businesses can enjoy greater reliability, support the local economy, and navigate complex regulatory requirements with ease. In today’s rapidly evolving market, investing in American-made PCBs is not just a matter of quality and efficiency — it’s a strategic move that positions companies for sustained success.

Contact us to learn how we can help you make a better product.

As a specialized Contract Electronics Manufacturer, we excel in high-mix, low-volume assemblies. Share your design, and we'll optimize your manufacturing process from start to finish.

Learn more:

(This article was originally published in October 2023 and was updated in October 2024 to provide up-to-date information.)

As today’s electronics designs become smaller and more complex, more engineers are relying on surface mount technology. After the 1980s, this...

The world of PCB assembly capabilities is changing rapidly, and forecasters expect PCB manufacturing capabilities to expand for the next 10 years....

When talking with salespeople, design engineers, and other contacts within an electronic contract manufacturer, you may hear a lot of terms thrown...