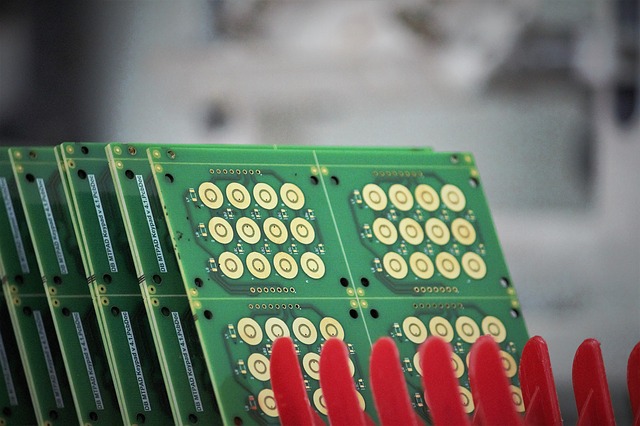

How Much Does a PCB Prototype Cost?

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

2 min read

Matric Group

:

Aug 31, 2020

Matric Group

:

Aug 31, 2020

Cable jackets serve as the first line of defense for wires and cables – which makes choosing the right jacketing material essential. So, you might be asking, what’s the best material for cable jackets?

As you might’ve expected, the answer is, “It depends.”

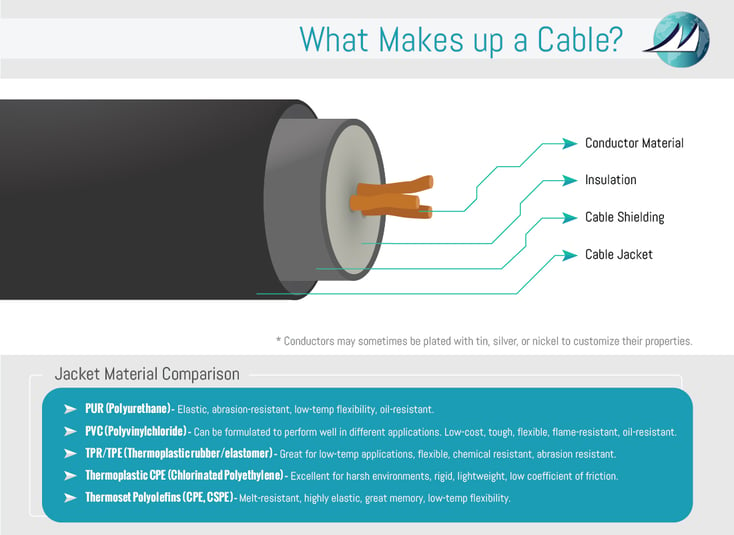

This quick cable jacket material comparison will breakdown the pros and cons of each material. But first, let’s break down what goes into a cable.

Although cables can contain a variety of components depending on their purpose, there’s a basic format that most cables follow. If you were to cut a cross-section from several different cables, you would likely find the following:

The best material for casing cable will always depend on the application, but in general, you can expect cable jackets to be of tougher material than wire assemblies because cables are used in harsher environments than wire assemblies.

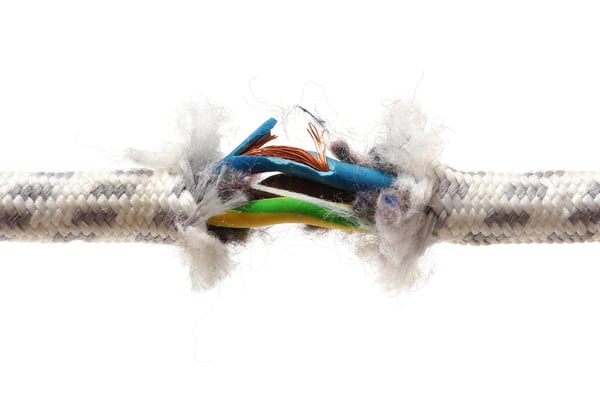

Cables jackets are designed to protect cables and cords in specific environmental challenges. A cable jacket might need to hold up to relatively minor wear and tear applications. Or, it might need to be extremely tough, such as a cable used in welding applications.

Wire assemblies, like a PCB cable assembly, are best for interior work like in personal computers and small electronics.

All that said, some cable casing materials are better suited for certain environments. Here’s how to know what ones to choose from.

There are at least five common casing materials for cables and cords:

We can’t say it enough: The end-use application plays a lot into deciding on a casing.

For example, PVC is commonly used in jackets for extension cords in homes and other residential applications because of its low cost and rugged construction. Thermoset polyolefins are a common electric cable casing in welding because they can withstand direct heat without melting.

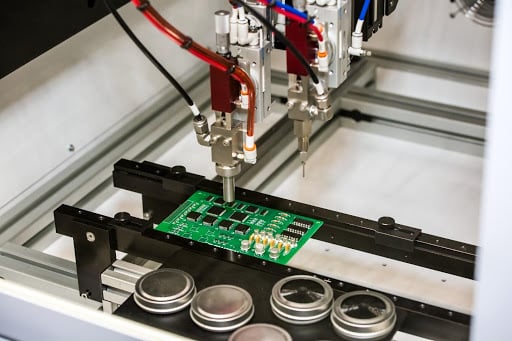

So now you’ve figured out what kind of cable casing material you want to go with. Your design looks great on paper. Always test your PCB or cable assembly to help you decide if the material choice is your final answer before production.

Check out our free guide to learn more about PCB testing, prototyping, and inspection.

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

With the rise of IoT and technology in general, electronics are featured in many environments, exposing delicate electronic connections to potential...

Box build assembly. Systems integration. Top level assembly.