How Much Does a PCB Prototype Cost?

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

The products that your organization is preparing to develop call for printed circuit boards (PCBs) -- simple enough, right? Not exactly. Components and boards come in many shapes, sizes, and materials.

One underappreciated PCB design consideration is the level of firmness of the board. Don’t start production without a thorough analysis of rigid PCB vs. flexible PCB pros and cons for your specific needs:

If you’re stuck on which type of PCB substrate makes sense for your design, rely on these five tenets:

Durability

DurabilityDoes your application call for a highly durable design?

Flex circuits are more durable because the low mass of the board significantly decreases risk of vibration-related damage. Because flexible PCBs are constructed with polyimide, they’re also well suited for high-heat conditions.

If your product needs to bend without breaking, both literally and figuratively, flexible PCB material your path to success.

When you route corners in a PCB design, don’t ignore the possibility of EMI (electromagnetic interference) being generated at right angles. If you’re working on a rigid PCB substrate, the design software experts at Altium recommend working with soft corners instead of the sharper, 45° corner you often see in rigid PCBs.

When working with flexible PCBs, take into account the bend ratio. This is expressed as a ratio of the thickness of the flexible PCB vs. the bend radius. Going below the bend ratio subjects the circuit to a higher possibility of mechanical failure.

When working out your budget, consider whether flexible PCB costs are worth it. In general, rigid PCBs cost less than flexible circuits. Use of rigid circuit boards often reduces the size and weight of your design.

At the same time, don’t dismiss flexible PCBs as too expensive. To get an accurate understanding of the total cost of ownership, examine your design and see whether flex circuits may eliminate the need for some components, including

All things considered, flexible PCBs might actually be more cost-effective. Consult with a contract manufacturer that specializes in PCB design assistance if you’re still unsure about the final price.

Electronics makers often place rigid PCBs in consumer devices, such as:

But for products that involve a more sophisticated design, or need to meet high performance standards, flexible PCBs are usually the first choice.

On the opposite end of design, another reason to work with flexible PCB is when you have a low-technology application such as LED lighting. Bendability makes for easier installation in places like kitchen cabinets.

Whether you're using rigid or flexible PCBs for your product, make sure you're still maximizing your design and avoiding common PCB layout flaws. Rigid or flexible doesn't matter if your board doesn't work!

PCBs that are flexible have many similarities to rigid PCBs, so here’s a recap of what you don’t need to worry about.

Evaluating PCB substrate types is of the utmost importance. You may want to conduct PCB testing early in the design process as you plan out project milestones.

It’s easy for a complex PCB design to contain subtle errors that escape the notice of a traditional peer-review process. Asking your PCB manufacturer to test your design gives you the advantages of modern, automated verification.

You can learn more about the many types of PCB testing here.

Hopefully, you now have a better feel for using the right PCB substrate material in the right situation. Depending on the development stage of your project, it’s possible you still have questions before deciding which route to take.

This is where it pays to partner with contractors who review PCB layout designs with best practices in mind vs. a board that mindlessly pumps out products.

To learn more about PCB design guidelines, check out this free chart of component sizes:

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

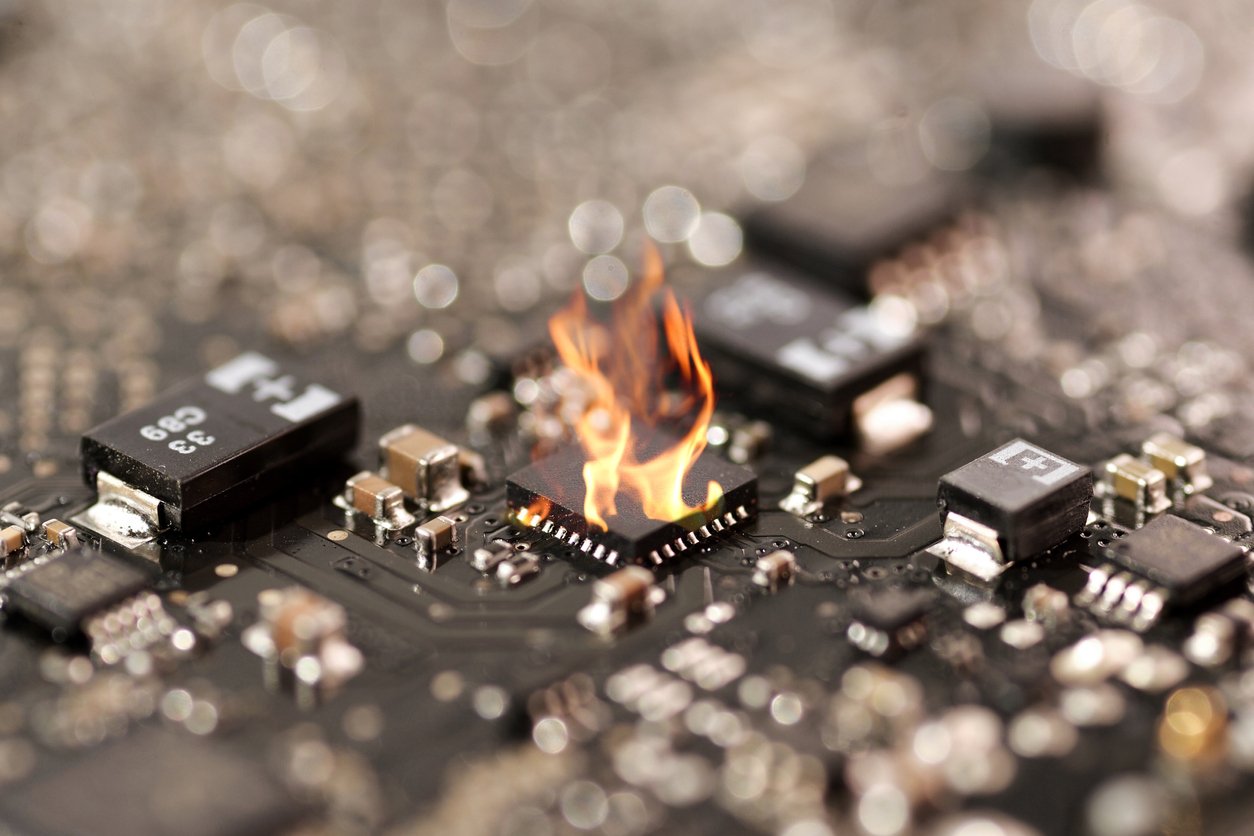

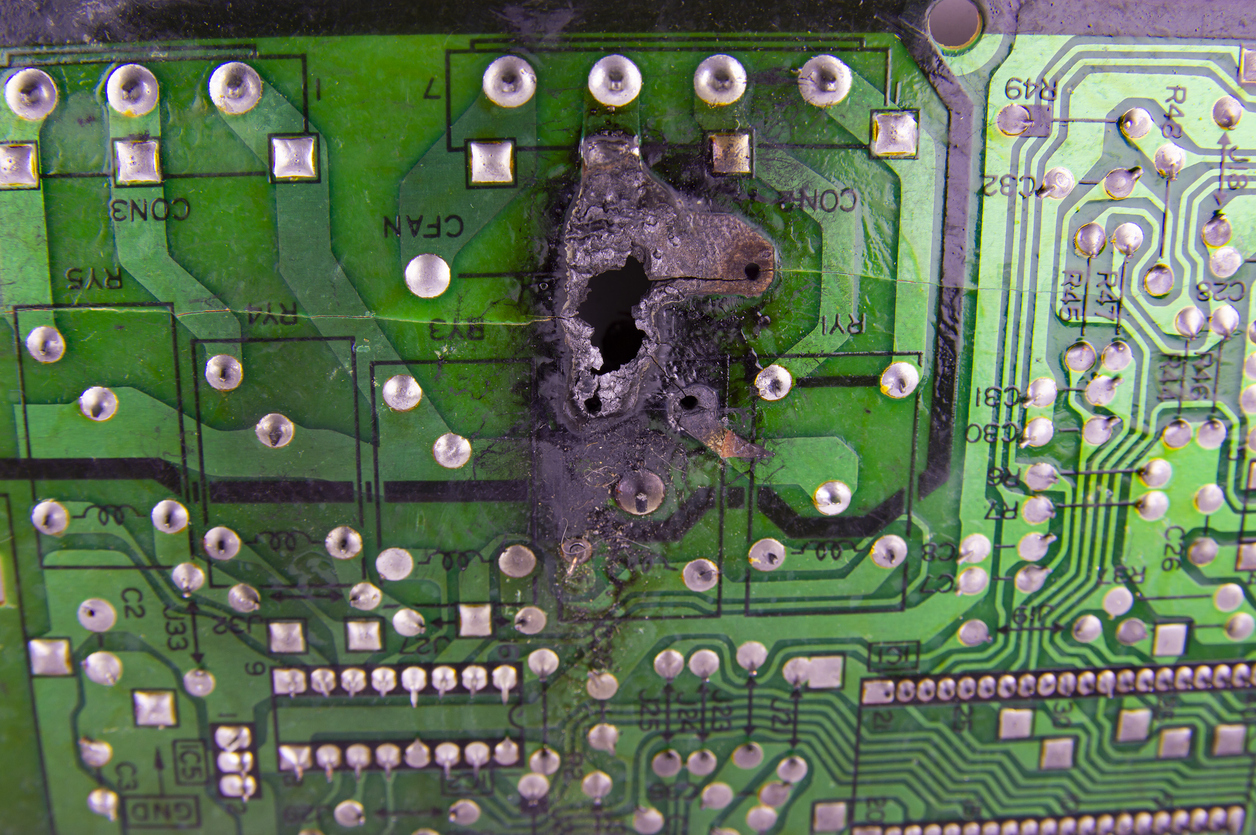

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...

Printed circuit boards (PCBs) are the foundation of almost every electronic product. When one fails, the results can include product recalls, costly...