Outsourcing a Box Build Assembly? Here's How to ID a Great Partner

Box build assembly. Systems integration. Top level assembly.

If you’ve put in the hard work of designing an electronic product, chances are you have high expectations for its success with your target market. But before you can get anything into the hands of customers, you need to have it in a project box that protects your carefully designed product and makes it truly useful and accessible.

If you’ve put in the hard work of designing an electronic product, chances are you have high expectations for its success with your target market. But before you can get anything into the hands of customers, you need to have it in a project box that protects your carefully designed product and makes it truly useful and accessible.

Designing an electronics box build assembly presents its own challenges -- but they are challenges you can overcome with the right approach. As you move forward, focus on the following aspects of your build to ensure you’re truly satisfied with the outcome.

If you have much experience working with manufacturers, you know that engineers and manufacturers can sometimes have a rocky relationship. Each wants to produce the best possible product, but the ideals of an engineer can run up against the real-world necessities of the manufacturing process. In the end, manufacturers have to be able to produce a tangible product -- and that can mean making compromises that frustrate designers.

Fortunately, these kinds of problems can often be avoided with a little forethought and appreciation for the requirements of manufacturability. When designing your box, try to keep in mind the limits of the manufacturing process, especially if you want to keep costs down. Manufacturers can accomplish amazing things, but the more specialized those things are, the more time consuming they become -- and the more expensive the process.

The materials you use for your box design should be determined based on the requirements of the product and most importantly, on the way you expect that product to be used. There are plenty of material choices out there, so it’s worthwhile to do your research and talk to people who have expertise in this area.

Your electronics contract manufacturer (ECM) is an excellent resource on material choices, as it should have extensive experience in making electronics box build assemblies for a variety of applications. The vendor you work with should be happy to discuss with you all the various details of how your box should be designed and what materials should be used in its manufacture.

There are a variety of electronic contract manufacturers out there, and many of them specialize in one area or another. A vendor that is the obvious choice for one project may not be the right choice for another, so examine your options carefully before you choose a partner.

For example, some electronics manufacturing service vendors specialize in large-volume manufacturing using the cheapest, most simple materials available to produce substantial orders. Other vendors are more geared toward specialized projects, focusing on smaller-volume orders that require more care and attention to produce successfully.

The right vendor will offer a range of services that help you achieve your desired result, including:

Product assembly

Packaging

Labeling

Testing

Order fulfillment

Before you choose a vendor, clarify what it is that you’re trying to do and what services are necessary to reach your goal. Then, you can interview potential vendors to determine if they have the capability to meet your unique requirements.

Don’t be afraid to ask the tough questions. Any reputable vendor will be happy to answer them.

As you can see, a big part of getting a box build assembly right is developing a solid relationship with a manufacturing vendor. This is for two reasons: You want your project executed correctly and you’ll really benefit from the expert design advice along the way.

For more on working with an electronics manufacturer, check out these articles:

Glossary of Terms Your Electronics Contract Manufacturer May Use

Guide to Getting Accurate Quotes From an Electronics Contract Manufacturer

Box build assembly. Systems integration. Top level assembly.

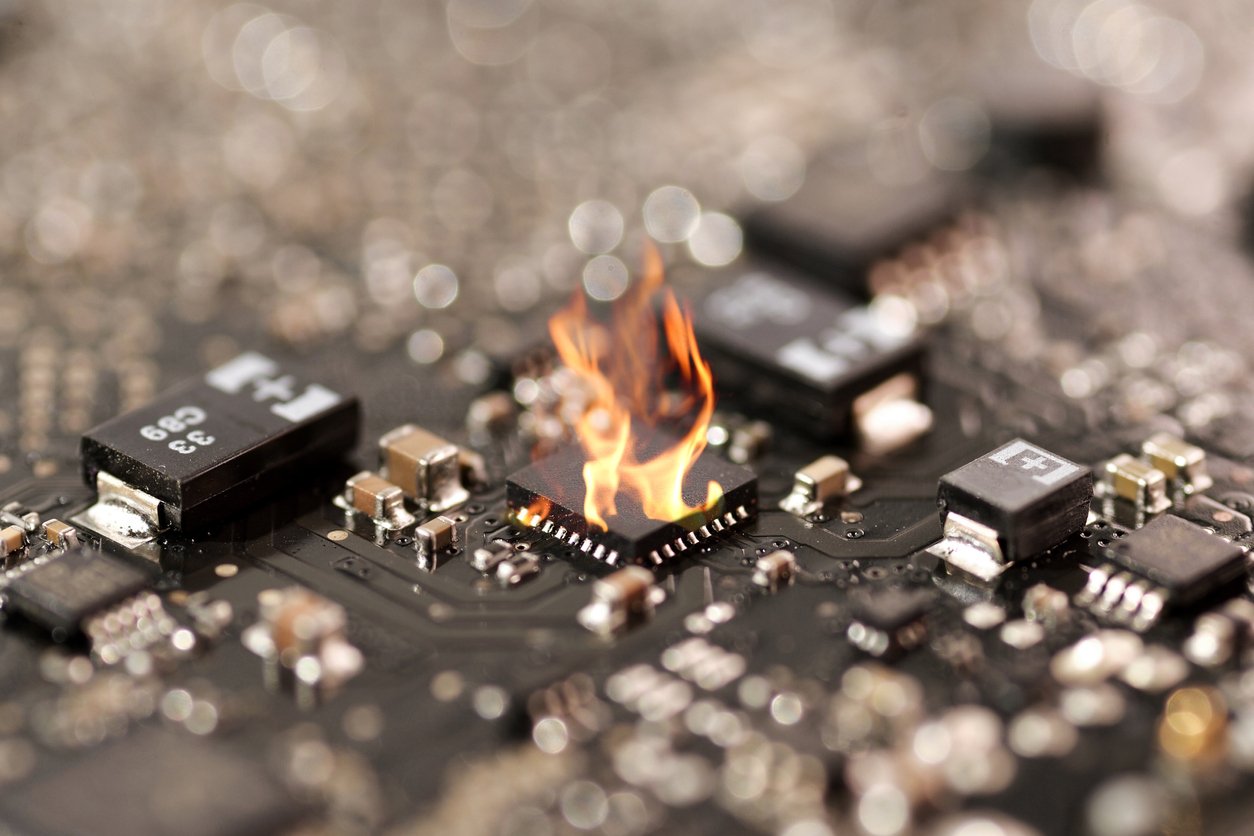

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...

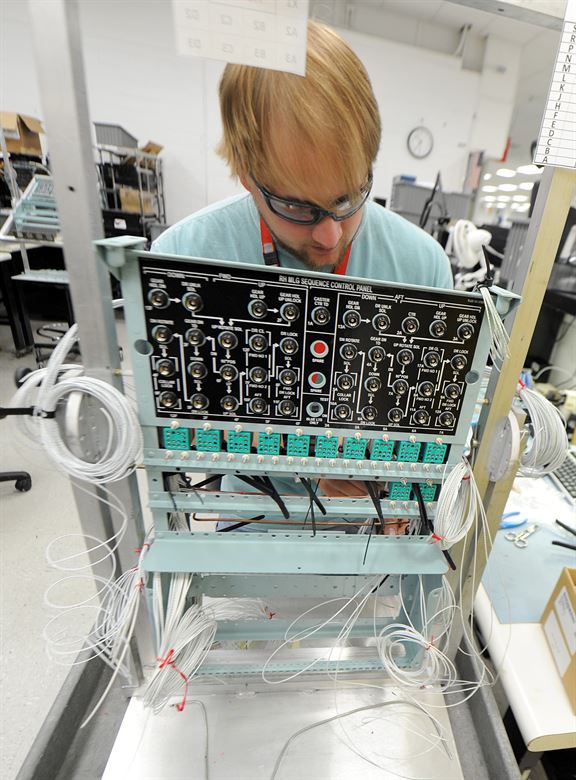

(Photo courtesy U.S. Air Force) Electromechanical PCB box build assembly services are one of the most important offerings of electronics contract...