Best PCB Substrate Types For Your Board

Most often, the foundation, or base, of a printed circuit board (PCB) consists of a substrate and laminate. Different PCB laminate and substrate...

The decision to single or dual source from electronics manufacturing services partners plays a heavy hand in determining the infrastructure of your supply chain. Each option has its advantages and potential hazards, and each OEM needs to determine the best fit based on its own size, order volumes, demand, etc.

Think of this decision as if you were developing your personal investment portfolio. You have one stock (let’s call it Stock A) that has a defined period of successful growth and reliability, with little risk. You could simply invest your money with Stock A, bypassing the complicated process of identifying similarly sustainable stocks, and hoping that it can deliver. The issue with this is the same as using a single supplier for your outsourced electronics materials – Using a single supplier is the equivalent of putting all your eggs in one basket. If your basket breaks, so do your eggs.

Going back to the stock portfolio metaphor ... you could also choose to diversify your portfolio, splitting your investments among several stocks to protect your money when issues arise. This also translates well to the electronics world. By using a number of suppliers -- just like with electronic component sourcing -- a company can reduce risk by having its supply divided among multiple electronics contract manufacturers (ECMs).

To determine which strategy works best for your company, let’s take a look at some of the important determining factors in supply chain management.

Choosing a supplier means knowing that they can handle any order your company can throw at it because it has the necessary

Electronics contract manufacturers typically fall into a certain category – low-volume, high-mix assembly; high-volume consumer assembly; and even specialization based on the market, such as military or medical electronics. If you’re using a single supplier, it’s important to determine that they “check all the boxes” when it comes to handling potential orders from your company.

Do they have the right certifications? Do your volumes match? It’s best to use a well-rounded ECM with a demonstrated history in your market if you choose them as your single source.

On the other hand, if you have a broad range of orders that require a specific manufacturing focus, you can opt to utilize multiple sources that meet the needs of varying orders.

Dual sourcing is the more popular route among OEMs, and pricing is no small reason why. By quoting out your orders among several suppliers you consistently work with, OEMs can often finagle a better price.

However, this isn’t always the case. If you split up volumes among different suppliers, you could lose out on pricing breaks you’d get by placing the whole order with one supplier.

This one is pretty simple. The more branches on your supply chain, the more work it will take to manage. If your operation can manage with one supplier, it could save you time and money by keeping a simple supply chain until a second source is warranted.

Supply and demand can change in a heartbeat. When your volumes increase, can your suppliers adjust? When orders are low or dormant, will your supplier remain interested in your business?

A single supplier may not always have the capacity to adjust on the fly to your volume changes, but with multiple suppliers, you can pivot orders to another supplier with the capacity to make it work.

Another thing to think about – if one of the ECM’s other customers experiences an increase in volume, what will happen to your order? If you have a single supplier, be sure to discuss what to expect in this type of situation and develop a plan accordingly.

The idea behind dual sourcing is reducing risk in the supply chain, and that’s what makes it the popular choice.

OEMs are generally more comfortable with spreading reliance around when it comes to electronics contract manufacturers. But it’s your confidence level in an ECM that should determine whether it should be your singular source of electronics.

Most often, the foundation, or base, of a printed circuit board (PCB) consists of a substrate and laminate. Different PCB laminate and substrate...

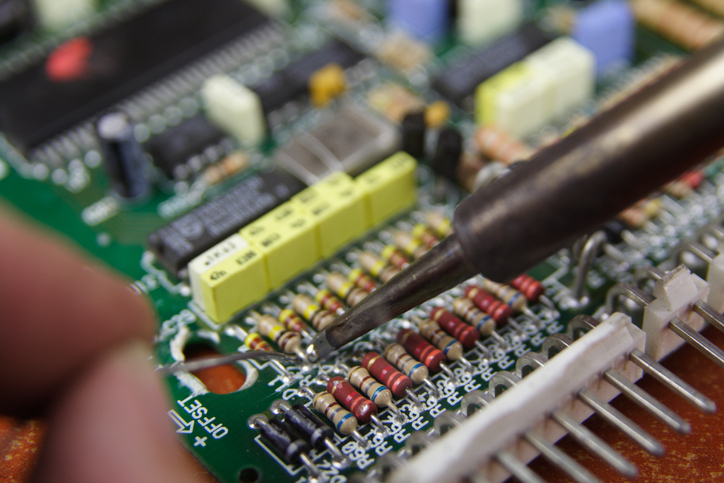

If you’re considering switching an existing electronic product design from through-hole technology to surface mount technology (SMT), you’ll want to...

When introducing a new electronic product design, many OEMs don’t fully understand the differences between IPC classifications -- or understand them...