LED PCB Design for Safety

At this point, we’re all familiar with light-emitting diode (LED) lights. From the bright, efficient bulbs replacing the old filament lamps, to the...

When reliable performance matters – whether in medical devices or handheld mining tools – every component in your design needs to contribute to safety and functionality. Reverse polarity protection helps printed circuit boards (PCBs) handle unexpected issues like incorrect connections or power fluctuations, safeguarding both the device and the people relying on it.

Incorporating thoughtful protection strategies allows you to build equipment that endures the challenges of demanding environments. This guide explores how reverse polarity protection methods, like diodes, can support dependable and long-lasting designs.

Reverse polarity protection is crucial for devices using direct current (DC) power, especially when there's a risk of misconnected batteries or incompatible adapters.

To better understand reverse polarity, consider daily-use items like car batteries. Reversed poles occur when you connect the negative cable with the positive, and vice versa. This can damage the battery and other electrical components.

If a battery-powered device is connected incorrectly, the reverse flow of current can energize parts of the circuit that shouldn’t be live, which may lead to unexpected behavior or, in rare cases, a risk of electric shock. Reverse polarity can lead to damage or even failure of PCBs, which can be difficult to identify visually. While the consequences of reverse polarity may not be severe for a laptop, they can be fatal when it comes to life-sustaining medical equipment.

It’s important to note that reverse polarity doesn’t apply to devices with alternating current (AC) connections.

To protect against reverse polarity in PCB design, it’s helpful to understand the situations that can lead to these problems. Some typical causes include:

|

Incorrect Battery Connection |

Connecting a battery with the wrong orientation can lead to reverse polarity, potentially damaging the connected electronic device |

|

Incompatible Power Adapters |

Using an AC/DC wall adapter with an incorrect polarity connector may result in a reverse polarity situation, causing damage to the device, or circuit |

|

Wiring errors during assembly |

Mistakes in the wiring or assembly of a PCB can result in reverse polarity, particularly when power connections are involved |

|

Component misplacement or orientation |

Incorrectly placing or orientating components on a PCB can inadvertently cause a reverse polarity condition |

|

User errors |

Improper handling or connection of electronic devices by users can also lead to reverse polarity issues. |

Recognizing the signs of reverse polarity and understanding its potential impact on circuits and components can help develop effective protection strategies. Some symptoms and consequences of reverse polarity include:

To protect against reverse polarity, circuits need to be designed to handle voltage fluctuations without sustaining damage. While many modern devices are built to prevent incorrect plug connections, this alone doesn’t fully address the problem. PCB damage can still happen during development and testing, highlighting the importance of thoughtful design.

There are two primary methods for protecting PCBs from reverse polarity consequences:

While neither solution is foolproof, both can significantly reduce potential harm and provide users with security.

Placing a reverse polarity protection diode in series with the electrical supply line provides a “shut-off” mechanism to halt the voltage flow. It doesn’t fix the reverse polarity, but it does stop it from doing more harm.

Essentially, the diode separates what remains of the circuit from the reverse polarity. When the anode voltage is lower than the cathode voltage, the diode won’t carry current.

Though effective and inexpensive, there are a few negatives to the reverse polarity diode approach. For example:

A Schottky diode presents neither of the problems associated with a reverse polarity prevention diode and is, therefore, the better solution. However, there is at least one shortcoming.

The Schottky diode allows much greater reverse current and voltage across the load. On the other hand, the reverse current is low enough that it shouldn’t be a big concern.

Frequently Asked QuestionsHere are some of the most frequently asked questions about reverse polarity protection: Q: How do I determine whether a protection or Schottky diode is better for my specific application?

A: Choosing between a protection diode and a Schottky diode depends on the specific requirements of your device. If cost is a major concern and the circuit’s power consumption is relatively low, a standard protection diode can be a suitable choice. However, a Schottky diode is often the better option for applications where efficiency and reduced voltage drop are critical, such as in high-performance or battery-operated devices. It’s also important to consider your device’s current and voltage ratings and consult with your electronics contract manufacturer to select a diode that aligns with the device’s operational demands. Q: How should a diode be oriented for reverse polarity protection?A: Installing a diode for reverse polarity protection starts with placing it in the appropriate orientation so it blocks unwanted current flow. A standard protection diode is typically installed in series with the power supply line. A Schottky diode should be placed similarly, considering its reduced voltage drop advantage. Testing the circuit after installation confirms that the diode is functioning correctly. Q: Are there additional methods or technologies beyond diodes for reverse polarity protection?

A: Yes. While diodes are commonly used, other methods for reverse polarity protection exist. For example, a P-channel MOSFET protects without the energy loss associated with diodes. Some modern devices incorporate smart ICs that automatically detect and correct reverse polarity issues. Mechanical solutions, such as polarized connectors, can also prevent incorrect connections from occurring in the first place. Each method comes with its own set of benefits and limitations, so evaluating the device's specific needs and operating conditions is crucial when considering alternatives. |

Protecting your PCBs from reverse polarity is crucial for keeping equipment safe and reliable, especially for critical uses like medical devices or mining tools.

A Schottky diode is often a smart choice, but thoughtful planning and proper installation go a long way in creating dependable designs.

The best approach is to prevent reverse polarity from happening in the first place, with diodes providing an added layer of protection.

Navigate the complexities of manufacturing standards with our free guide – your go-to resource for staying on track.

Editor's Note: This blog was originally published in June 2020 and was recently updated to reflect current industry trends.

At this point, we’re all familiar with light-emitting diode (LED) lights. From the bright, efficient bulbs replacing the old filament lamps, to the...

When turned on, electrical equipment generates sparks. Some equipment generates heat that can lead to ignition, while electric arcing occurs between...

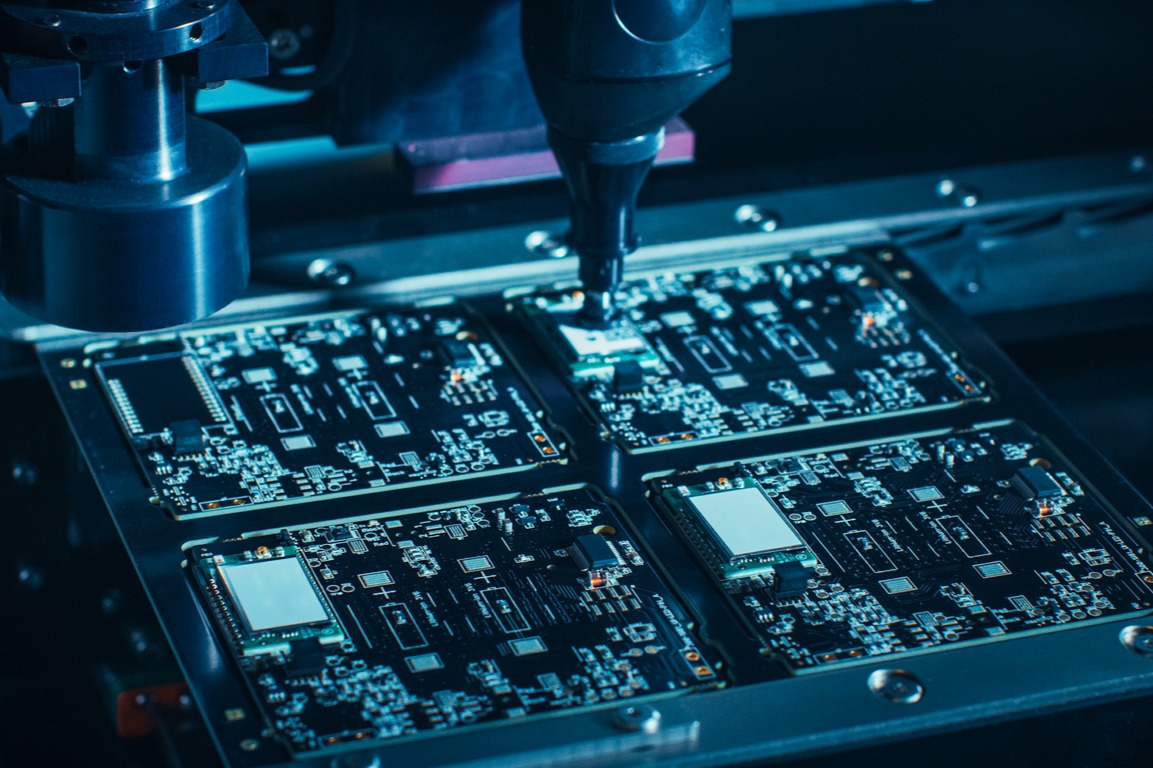

As electronics have become increasingly embedded in our day-to-day, the manufacturing process for printed circuit boards (PCBs) has adapted....