What Are PCB Functional Testing Services?

Electronics manufacture and testing are like squabbling siblings. PCB testing is a necessary expense that, when done correctly, prevents much larger...

There is no shortage of reasons to test a PCB assembly, and there is no shortage of ways to do it. Out of the many functional tests available, PCB microsection analysis has a pretty specific purpose.

There is no shortage of reasons to test a PCB assembly, and there is no shortage of ways to do it. Out of the many functional tests available, PCB microsection analysis has a pretty specific purpose.

Is it a test your electronics project needs? Quite possibly.

Let’s look at how a PCB microsection analysis works and what it tests for:

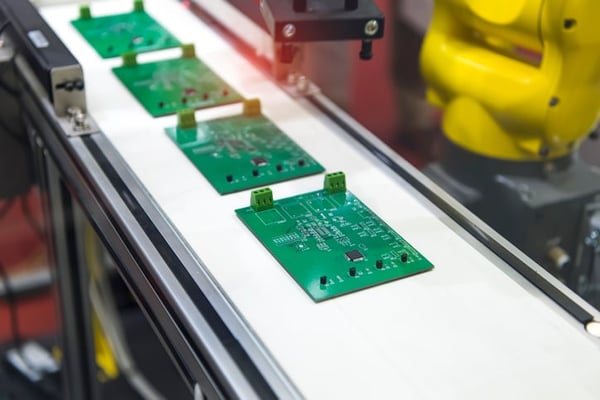

Functional testing, as opposed to some other tests, checks the entire assembly, helping prevent failure and shortened service life. It’s performed at the end of the manufacturing process.

Specifically, microsection analysis (also called a PCB cross section procedure) is the first choice for checking PCB plated through-hole integrity. It takes place in these five steps:

Microsection analysis is a destructive test. So it’s performed on a sample of PCBs, not the entire manufacturing run. The test allows evaluation of the plated through-holes and the lamination. It also examines a part of an assembled PCB for problems such as such as:

In other words, microsection analysis provides a rather comprehensive picture that helps identify and compensate for potentially costly imperfections.

Defective components can be removed, exposed by abrasion and compared to components that are performing the way they should.

Microsection analysis is not easy. The materials that make up a PCB are of different hardnesses, as are the media used for mounting.

Additionally, the prep work is exacting. It must be completed no more than 10% beyond the plated through-hole's center. This level of precision requires specialized equipment and trained personnel who should be IPC-A-600 and IPC-A- 610 certified. Consequently, it’s often performed in a laboratory.

Don’t forget this type of PCB testing is destructive, so you’ll have to factor those destroyed boards into your cost considerations.|

Class 1, Class 2, and Class 3 electronics manufacturers can all benefit from microsection analysis, but for many Class 1 and Class 2 applications, it might be unnecessary. This is not the case for Class 3 electronics, such as those used in medical and military applications.

Microsectioning can also be used in SEM (scanning electron microscope) analysis. In SEM analysis, an electron beam scans the sample’s surface to dig up information about topography and composition.

The best way to decide whether your electronic products and your company will benefit from microsection analysis is to talk with your ECM (electronics contract manufacturer).

Besides PCB microsection analysis, functional PCB tests include:

Your ECM can determine whether one test is enough or you should explore other options.

Find out which tests your ECM offers and whether they fit your specific project requirements. Then discuss the most economical and efficient way to accommodate for testing.

The right testing choices can actually improve your bottom line. Not to mention your company’s reputation of delivering a great product!

Electronics manufacture and testing are like squabbling siblings. PCB testing is a necessary expense that, when done correctly, prevents much larger...

PCB contamination testing is not for every project, but it’s a lifesaver for some.

When you order printed circuit boards (PCB), you know the pricey consequence of failure. The last thing you need financially is for your PCBs to...