Obsolescence: A Pain in Medical Device Product Life Cycle Management

Medical device product life cycle management is a challenge at the best of times. It becomes even harder when supply chains are disrupted (such as...

2 min read

Matric Group

:

Jan 25, 2024

Matric Group

:

Jan 25, 2024

Global supply chain shortages mixed with bottlenecks in the shipping industry and labor shortages have triggered serious problems in nearly every industry. With price increases and supply shortages, electronics obsolescence is becoming an inevitability throughout many markets.

Rising demand has decimated inventory, forcing OEM manufacturers to second-guess their current product lineup and which devices they still service.

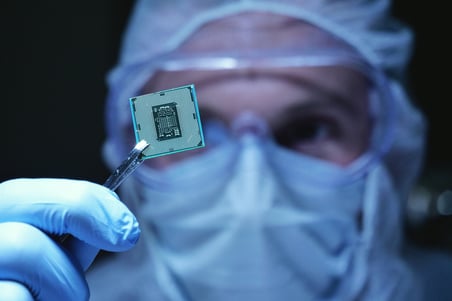

This is especially problematic for the medical field and for medical devices that are heavily reliant on their printed circuit boards (PCBs), and chips.

With no clear idea of where to source replacement parts, many medical professionals have turned to on-shore electronic contract manufacturing.

Most medical and electronic Printed Circuit Boards (PBCs) are produced overseas, however, even under ordinary circumstances, this leads to extended shipping times, translation difficulties, and potential issues during transit.

Further, when errors in manufacturing occur, parts are defective, or a wrong component is shipped, delays can stretch out months, and in some cases, years.

With the COVID pandemic still raging in some parts of the world, these problems have only been exacerbated by staffing shortages, global parts shortages, and shipping backlogs. Nearly every industry saw massive delays and increased shipping rates in overseas manufacturing.

In particular, for the medical industry, the global component shortage has delayed some orders 8-10 months, with legal and medical issues compounding, and medical device OEMs have had to face serious concerns over device obsolescence.

The shortages and bottlenecks in the supply chain have made obsolescence risk mitigation much more difficult. Some medical device manufacturers may need to plan several years ahead to ensure their equipment does not become unserviceable.

While obsolesces in medical devices is a major problem for medical professionals and healthcare organizations, the patients are those who suffer the most.

But the good news is that coping with these growing difficulties is no longer complex, thanks to domestic electronics contract manufacturers. While ECMs (electronics contract manufacturers) can’t solve these problems overnight, finding a reputable ECM with experience in the medical industry can protect your patients and reduce the risk of obsolescence.

More and more medical device manufacturers are turning to ECMs to produce the electronic components in their devices. The advantages of working with onshore ECMs are straightforward: They help maintain inventory and ensure timely shipments.

But that’s just the start of what an on-shore ECM can provide a medical device manufacturer. Domestic ECMs also offer:

A Single Point of Contact: If you have a problem, one phone call can set the solution in motion

Faster Concept To Finish Processing: With shorter shipping routes, fewer checkpoints, and simple contact lists, new designs can find their way to the production floor more quickly

No Loss in Translation: Translation inefficiencies lead to all manner of problems including the wrong electronic component being shipped

Reverse Engineering: If you’re working to understand a piece of equipment to perform on-site repairs, having a domestic ECM makes things much easier

On-Site Engineers: With engineers on-site at your original equipment manufacturer, you can work with them to solve technical problems and optimize your equipment

Vetted Suppliers: With foreign ECMs, you don’t always know who supplies materials. You may be working with a dispatcher who routes your order to a supplier you might not ordinarily want to work with. With local ECM, you work with the suppliers you trust most

Local ECMs are more able and willing to provide technical support when something goes wrong. In the medical industry, having a good medical device electronics design is just part of the equation. For competitive functionality, you need an ECM close enough to provide the services you need.

At Matric, we take pride in our ability to manufacture, design, engineer, and remanufacture electronic goods. We are optimally positioned to help you avoid and mitigate foreseeable obsolescence issues. Best of all, our domestic supply capabilities and willingness to help mean your obsolescence management needs will never get lost in translation.

Contact us today with any questions, or click below to learn more about Matric’s services and manufacturing capabilities:

(Editor's Note: This blog was originally published in April 2022 and has been updated in January 2023 with the most current information.)

Medical device product life cycle management is a challenge at the best of times. It becomes even harder when supply chains are disrupted (such as...

More opportunity, more money … and more problems.

Medical device companies looking for a PCB design and assembly partner have many important factors to consider, all with the end user’s well-being at...