Embedded Systems & IOT in Electronics Manufacturing – An Explainer

Perhaps without realizing it, you use embedded systems and IoT every single day of your life. “I use what?” you might’ve just asked.

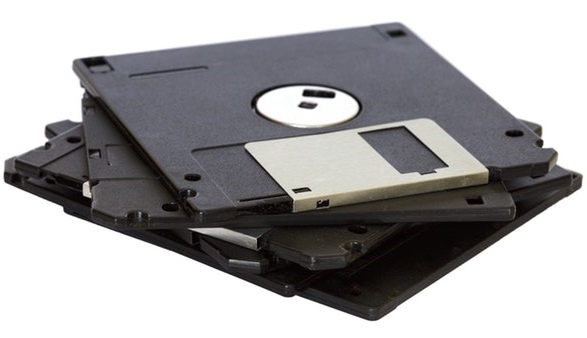

The most painful part of developing with electronics is knowing your success is fleeting. Eventually, all parts must die, or at least fade away into irrelevance. But there’s something you can do about it. Obsolescence management can guide you through this difficult process.

The most painful part of developing with electronics is knowing your success is fleeting. Eventually, all parts must die, or at least fade away into irrelevance. But there’s something you can do about it. Obsolescence management can guide you through this difficult process.

Here’s a rundown of the dying process in electronics, plus how the manufacturer makes it a little less -- or more -- painful.

Sadly, electronic components are becoming obsolete faster than ever before. Why?

Did that last point give you pause?

Until 10-15 years ago, the electronic components industry was driven by automotive companies. Today, it’s all about cell phones. If a parts manufacturer can get its chip into an iPhone design, a lot of money is coming.

Parts makers assume that modern consumers are constantly in the market for the “next new thing.” So makers of components for consumer tech often don’t bother to make anything that’ll last long. Today, the average life cycle of a new integrated circuit is under 2 years. Irritating, no?

These tech problems annoy us all, but humans are procrastinators by nature. We tend to let things slip from our minds until they become huge headaches.

Failing to manage aging electronic parts correctly can lead to:

Here’s what happens: A part goes obsolete, so brokers go out and buy stock in it. They want their profit while it lasts. As the chip or other component gets rarer, they raise the price.

Here’s another unpleasant scenario: Your part goes obsolete, and you’re desperate because you didn’t prepare. Since obsolete parts tend to end up in the black and gray markets, you may end up with a counterfeit component. If you place a fake component in your product unknowingly, it could stop working or, even worse, blow up in the field -- resulting in a huge monetary setback or even loss of life.

There are various notifications your part’s manufacturer may send out when its usefulness is coming to an end:

There are many reasons you might be left for dead without knowing it. Some are preventable; others aren’t:

While obsolescence is often out of your control, there’s plenty you can do on your own to fight other electronic component shortages.

And one final thought on shortages specific to obsolescence: It pays to work with a contract manufacturer that has an engineering arm. The contractor who’s putting together your circuit board can be your savior when it comes to a lot of these problems, actually. Many well-rounded providers offer life-cycle analysis and other obsolescence management services as part of their electronic manufacturing services.

So don’t leave your product for dead -- stretch its life out with these strategies and revive your supply chain!

For more on the benefits of obsolescence management, click the button below.

(Editor's note: This blog was originally published in May 2018 and was updated in June 2023 to reflect current information.)

Perhaps without realizing it, you use embedded systems and IoT every single day of your life. “I use what?” you might’ve just asked.

Change management is usually a requirement in the electronics industry. This specifically relates to changes needed after the initial design of your...

In 2006, the European Union rolled out a directive restricting the use of certain hazardous chemicals. This directive, Restriction of Hazardous...