7 No-Brainer Reasons to Prototype Your PCB Assembly

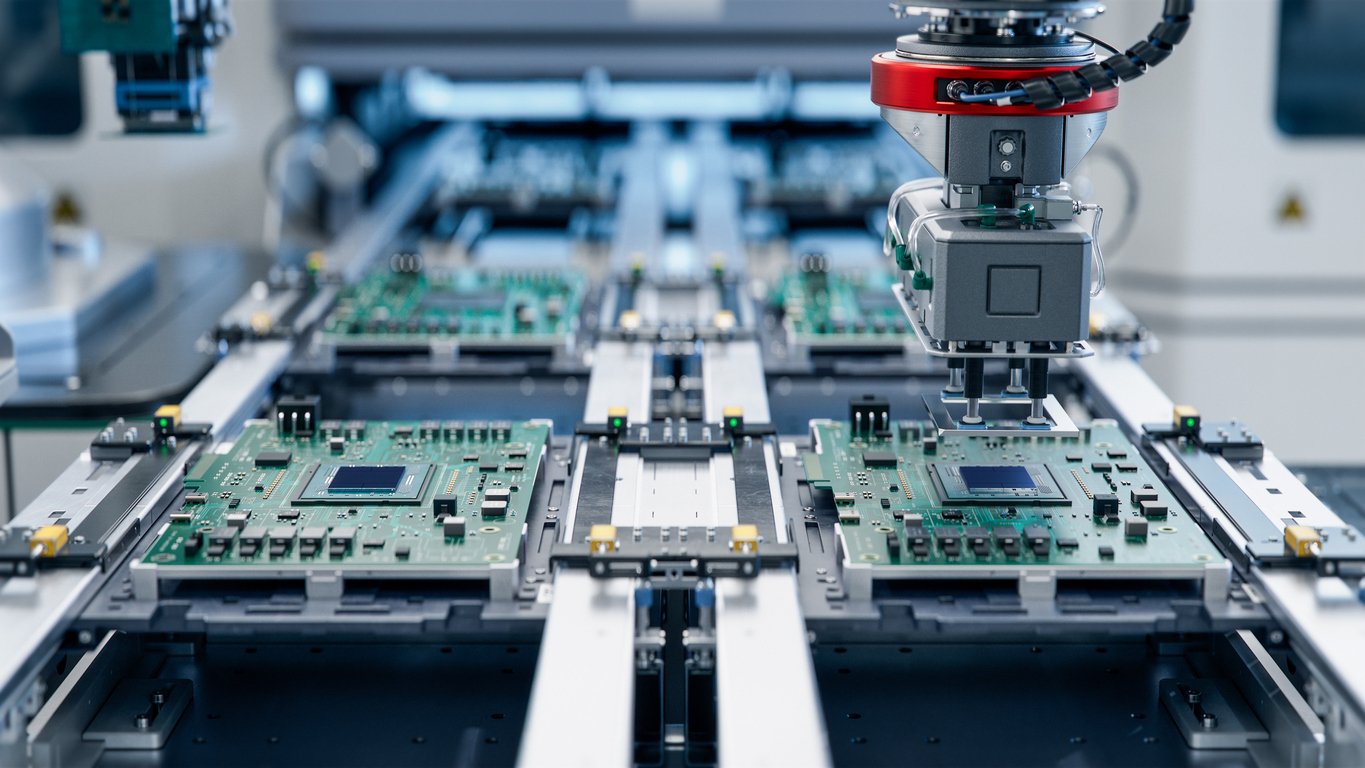

Prototyping is just as important to the electronics manufacturing process as designing, engineering, and testing. Ignore it at your own risk.

2 min read

Matric Group

:

Feb 21, 2020

Matric Group

:

Feb 21, 2020

Change management is usually a requirement in the electronics industry. This specifically relates to changes needed after the initial design of your project. In the electronics industry, an engineering change order (ECO) is the most common example of change management.

Change management is usually a requirement in the electronics industry. This specifically relates to changes needed after the initial design of your project. In the electronics industry, an engineering change order (ECO) is the most common example of change management.

Most businesses have an ECO process. But any good business is always looking to improve on it. Fortunately, there are numerous ways they can achieve that goal.

Let’s take a look at some commonplace ECO issues and ways you can streamline the process to keep you and your electronics contract manufacturer very happy.

The engineering change order procedure goes by several other names:

They all point toward the same thing: The electronic product maker is either asking about or demanding a change in process or equipment. In the case of electronics, an ECO may also be wise when components in your product are nearing end-of-life status or production costs are running too high.

If you manage them poorly, engineering change notice procedures can vastly increase costs. Use the tips below to be quicker, faster, and more flexible in your manufacturing process:

This issue permeates into other areas of business as well, but the use of paper ECOs can really inhibit your company’s level of communication. While hard copies are nice to have in some occasions, the ability to access digital notices can make life much easier in terms of sharing the notice and making notes and amendments. It also gives you the ability to archive ECOs for future reference, so you know what changes have been made in the past.

To remedy this problem, Matric Limited and Dynamic Manufacturing have installed nearly 200 digital workstations across their respective facilities. These remote desktop environments allow seamless sharing of ECOs and the ability to access the same information from anywhere on site. This also helps in the protection of intellectual property, reducing the chances of hard copies lying around or leaving the facility.

In all, the move to digital is a logical and increasingly necessary step. It connects your manufacturing floor with engineering, resulting in quicker and higher quality communication and making the whole change order process much more efficient.

Once you’ve determined the engineering change notice process is necessary, you can streamline it from the very beginning. If you present your manufacturer with the proper information up front, it can reduce a lot of the back-and-forth that bottlenecks the process and simply allows the manufacturer to get to work.

Use this engineering change note format to remember the information you should always supply your manufacturer up-front:

Use this engineering change notice template to get things right the first time. Disconnects between drawings, ambiguous markings, unintended omissions, and unintended additional changes can cost your company major time and money.

Spend additional time at the outset of the ECN process, confirming the accuracy of the information before its shared with manufacturing. This will reduce the headaches that come with unexpected issues down the line.

Lead times and electronic component availability are critical in many industries. For example, an engineering change order for medical devices is extra-important because any snag in producing life-saving equipment could result in a deadly shortage.

Obsolescence management is a huge part of maintaining uptime in production. To learn more about how inventory management and forecasting can make change management much easier, Click below:

(Editor's note: This article was originally published in July 2018 and was recently updated.)

Prototyping is just as important to the electronics manufacturing process as designing, engineering, and testing. Ignore it at your own risk.

When you’re looking for a PCB engineering services provider, there are, of course, multiple things to consider. “Will they be able to meet my...

Legacy electronic systems often remain in service far longer than originally expected. Industrial controls, medical equipment, transportation...