Understanding PCB Contamination Testing for Reliable Builds

PCB contamination testing is not for every project, but it’s a lifesaver for some.

Electronics manufacture and testing are like squabbling siblings. PCB testing is a necessary expense that, when done correctly, prevents much larger and more embarrassing damage control when your product goes to market.

Electronics manufacture and testing are like squabbling siblings. PCB testing is a necessary expense that, when done correctly, prevents much larger and more embarrassing damage control when your product goes to market.

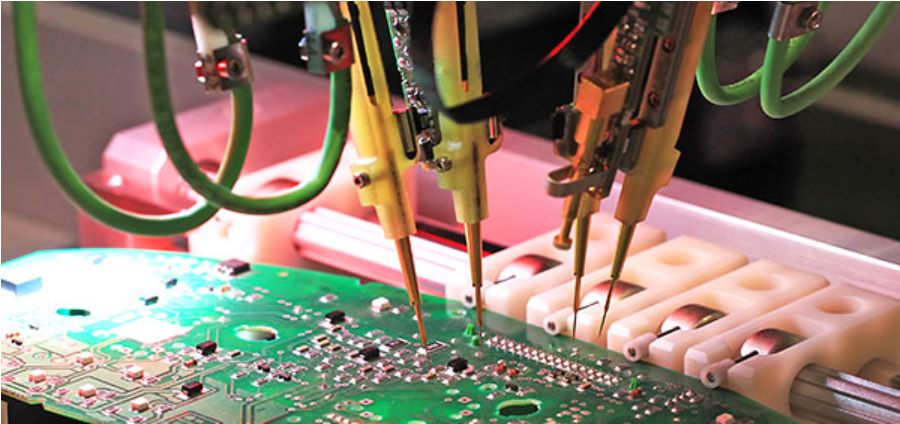

Functional PCB (printed circuit board) testing is performed at the end of the manufacturing process to ensure that the manufactured part will not fail immediately or have a shortened service life.

Let’s distinguish between PCB functional testing services and other PCB testing, then get into the specifics and advantages of each.

Functional types of PCB testing include:

Why ask for functional testing instead of another type of PCB test? Functional PCB testing has some clear benefits, such as:

PCB functional test systems examine the whole assembly, not just its components. This kind of circuit board testing simulates the environment in which the actual assembly will be required to perform. With functional testing, it’s possible to test up to 100% of the products before an ECM ships them to an original equipment manufacturer (OEM, AKA you).

Here are some popular PCB functional tests and how they do their job.

Also known as AXI, automated X-ray inspection for PCBs involves 2D or 3D digital images that show every layer of the board. So, the inspection is completed in one move. The procedure allows a look at the workings of the entire board. A schematic provides a reference for comparison.

Among the advantages of AXI are:

AXI does require operators with training and experience, but that’s a nonissue if you’re working with a contract electronics manufacturer you trust. The test can result in significant time and cost savings in spite of the additional personnel expenditures.

RELATED POST: Auto Inspection Makes Your Contractor Productive

Sometimes called cross-sectioning or metallographic preparation, PCB micro-section analysis takes a 2D sample that reveals inner workings. The test helps identify:

Micro-sectioning is destructive to a device under test (DUT), but with it, a component that isn’t performing properly can be removed. The component is then put into a curing epoxy, exposed by means of abrasion, and compared with a functioning component.

With a closer look, a technician can see:

PCBs can be contaminated in more ways than we care to admit, including:

The results of contamination can include, among others:

PCB contamination happens frequently. So testing for it is essential to proper component performance.

Known also as resistivity of solvent extract, or ROSE, testing, contamination testing is designed to find the bulk ionics and contaminate boards. The process involves a zero-ion or other ionic testing unit drawing ions on the board into a solvent. The ionic contamination is then measured and plotted on a curve to compare it to industry standards.

RELATED POST: All About PCB Contamination Testing

Testing component and PCB pad solderability can help:

This test is great for a variety of production factors:

RELATED POST: All About PCB Solderability Tests

Although designed to identify faults and discontinuities in metallic cable connectors and other electrical paths, it also works for PCB testing.

Specialized TDRs can be used to locate failures in high-frequency boards, particularly those that act like transmission lines. The instrument spots reflections revealing unsoldered pins of a ball grid array, short-circuited pins and more.

Peel Test

Peel TestAs a general rule, peel tests intended for flexible adhesives measure resistance to highly localized stresses. Specific to PCBs, this test measures the strength needed to peel laminate from the board.

Also called a thermal stress test, he float test determines the amount of heat-related stress a board’s holes can withstand. This includes both the range of temperature and the number of heating-cooling cycles a board can handle.

The test can sniff out potential delamination and bad solder joint connections.

Work with your electronics contract manufacturer on a case-by-case basis to determine whether you need functional testing or a more intensive (and expensive) test -- or both.

There are many other PCB assembly testing methods that may be a better match than what's listed above. These include:

To figure out which combination of in-circuit and functional tests will help ensure the highest quality for your PCBs, talk to your electronics manufacturing services provider early and often. Doing so in the design phase will ensure the design is not only able to be manufactured, but also is compatible with the tests ideal for your project. Bonus points for your electronic manufacturing solutions partner if it has both testing and design assistance capabilities!

PCB testing pique your interest? Learn more about testing, prototyping and inspection with this free e-book!

(Editor's note: This article was originally published in June 2019 and was recently updated.)

PCB contamination testing is not for every project, but it’s a lifesaver for some.

When you order printed circuit boards, you already understand the costly consequences of failure. The last thing you need is for your PCBs to...

Deciding on the best testing method for your printed circuit board can be a daunting task. There are plenty of factors to take into consideration,...