Story of an American Electronics Manufacturer Pt. 1: The 1970s

The year is 1971. Carole King's' hit single "I Feel The Earth Move" is playing through a Plymouth Volare as two electrical engineers/teachers enter a...

3 min read

Matric Group

:

Aug 25, 2021

Matric Group

:

Aug 25, 2021

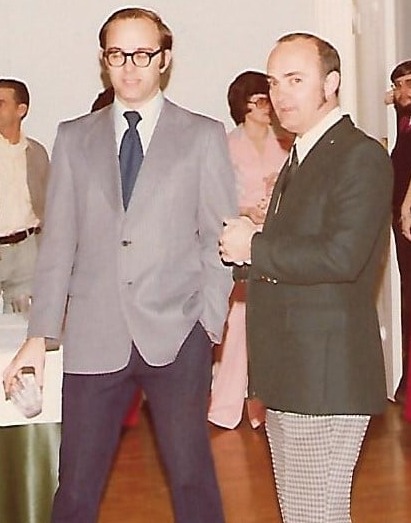

As we continue the countdown to Matric's 50th anniversary, let's recap so far the 1970s and how it all started. In part one of this series, we discussed how a shared passion for Ham Radios led two electrical engineers turned vo-tech teachers, Lee Richey and Andy Maitland, to open a new business that designed, manufactured, and repaired electronic devices.

Their products ranged from their PADDLE Model 11A, a small morse code device, to radio-controlled multiplex systems used in the mining industry.

Up next… The 1980s - from the first space shuttle launch to actor turned politician Ronald Reagan's presidential election to the release of Windows; it is safe to say the 1980s was a decade that pushed all kinds of boundaries. That couldn't be more true for Matric Limited.

For Matric Limited, the 80s started with gross sales over $275,000 and a 12.8% wage and salary increase. In May of 1980, they invested in a mainframe system to use in production and assist with quoting but quickly realized they had no idea how to spec the equipment for the needed work.

It was purchased primarily for business applications, i.e., quoting, purchasing, etc., it was not used for engineering or production.

So in 1983, ENTER – KAPROS (Fig. 1) on every desk, networked throughout and a Condor database! Although the original purchase of the mainframe ended up being a slight financial loss, the knowledge obtained positioned Matric as one of the first companies locally to understand this up-and-coming new technology. With that knowledge, they expanded yet again.

ENTER - Computer Showcase, The Learning Center, & CSOnline. A retail computer store and training facility specializing in residential and commercial systems, educational training, and industrial hardware, software, and installation.

However, all of this took place while recovering from a tremendous loss. In October of 1982, a fire broke in the production and engineering trailer. The fire resulted from a flow solder machine that had just been installed.

Matric had already outgrown the 2500 sq. ft. building and were using two trailers to handle the overflow while another 7,500 sq. ft. addition was under construction. Everyone worked in tight quarters during the recovery and even assisted with finishing the newest addition.

In May of 1983, Matric sold a radio remote control system to a company in Delaware, who sold it to a company in Ireland, who in turn sold the equipment to the Iraqi government. The system was used to raise a net to catch wounded aircraft at the end of runways at Kut and other airforce bases. Someone in the supply chain had changed the frequency requirements in the crystals (Fig. 2) used in the system, which caused the equipment to become unusable.

The crystal replacement could not be accomplished by the Irish company that sold the equipment, so Matric was called upon to troubleshoot. When Lee Richey, the president of Matric, flew there to assess and replace the crystals, the crystals weren't there. The Iraqi government requested Lee stay until the system was operational. Andy Maitland, vice-president of Matric and Lee's wife and Matric's secretary Jane, pulled every string possible locating and shipping the crystals so Lee could return home safely. He was back in the states in late May 1983.

As the 1980s continued, Matric's list of products and company list grew substantially. A unique radio product called the Matric Herald (Fig. 3,) a radio made by Kachina and modified specifically by Matric for the mission field needs, achieved some success.

As this product was in demand, in July of 1984, it led to an invitation by the United Methodist Church in Zaire, who had obtained a grant from USAID to install non-directional solar-powered beacons to aid the communication for mission pilots. Lee and Jane made a 5-week trip to Zaire to do the installation. Unfortunately, a few years later, The project was destroyed by rebels, and the missionaries were evacuated safely from the area. Zaire is now called The Congo.

Nearing the end of the 1980s, with gross sales over $2.4 million, Matric Limited continued to make investments in the business to assure a solid future for the company.

Joy Mining business markedly continued to increase their business. An opportunity to invest $600K in acquiring the inventory and board designs of the RCA Microboard line was a major step forward in expanding capabilities. Shortly thereafter, a substantial low-interest business loan was obtained to purchase new Surface Mount Technology or (SMT) equipment. Satisfied customers, a quality employee base, and biblical management principles enabled the company to become a world-class provider of THT and SMT assembly, engineering, and aftermarket services. Up next, the 1990s!

COMING SOON: PART 3 "THE 90s"

The Hubble Space Telescope launches. The Gulf War begins. The World Wide Web debuts and...

If you need help choosing the right electronic manufacturing services company to partner with, or have any questions about machine capabilities, check out our capabilities/services brochure below:

The year is 1971. Carole King's' hit single "I Feel The Earth Move" is playing through a Plymouth Volare as two electrical engineers/teachers enter a...

(Editor’s note: This is part 3 of a six-part series on the history of Matric Group, from a $20 investment in 1971 to a $60+ million business today.)

When designing solar-powered embedded systems intended for outdoor applications, durability, performance, and energy efficiency are a perfect storm...