A Closer Look at PCB Solderability Testing in Electronics Production

Solder is what makes the electrical connections work on your printed circuit board (PCB). Solderability, then, measures how well metal is wetted by...

5 min read

Matric Group

:

Mar 07, 2025

Matric Group

:

Mar 07, 2025

The tech world moves at lightning speed.

Bringing an electronic product to market requires more than just a great idea — it demands precision, efficiency, and flawless manufacturing.

Whether you’re launching the latest consumer gadget or developing mission-critical medical equipment, one essential component underpins it all: the printed circuit board (PCB). Yet, producing high-performance PCBs in-house is often too complex and costly for many companies.

That’s where turnkey PCB assembly steps in, offering a streamlined, all-in-one solution that takes you from concept to completion without the hassle of juggling multiple suppliers. By handling everything from component sourcing to final testing, turnkey PCB services help you bring products to market faster, reduce overhead costs, and ensure top-notch quality at every stage.

Let’s dive into how turnkey assembly can simplify your manufacturing process and help you bring exceptional products to life.

Turnkey PCB assembly is a comprehensive manufacturing solution where a single provider handles the entire PCB production process — from sourcing components and fabricating the board to assembling and testing the final product. The term “turnkey” means that the product is delivered ready for immediate use, eliminating the need for multiple vendors or complex supply chain management. This is also known as a box build.

Unlike traditional PCB assembly methods, where customers must coordinate between multiple suppliers, PCB turnkey solutions consolidate everything under one roof, simplifying project management and reducing lead times.

Companies can choose between full turnkey PCB and partial turnkey assembly, depending on their needs:

Turnkey PCB assembly offers a comprehensive solution for businesses looking to streamline their electronics manufacturing process. This approach eliminates the complexities of managing multiple suppliers, ensuring a more efficient and reliable manufacturing experience.

Key benefits of turnkey PCB assembly include:

One of the biggest advantages of turnkey PCB manufacturing is cost efficiency. By consolidating all aspects of production into a single PCB manufacturing company, businesses can:

Many companies underestimate the costs associated with managing multiple vendors. Handling procurement, inspections, and logistics separately can significantly inflate expenses. Turnkey contract manufacturing helps eliminate these inefficiencies, making it a more cost-effective solution.

Speed is crucial in electronics manufacturing, especially in consumer electronics, medical devices, and automotive industries. Turnkey PCB assembly accelerates product delivery by:

With turnkey contract manufacturing, businesses can get products into customers' hands faster, gaining a competitive edge. Reducing production cycles can mean the difference between market leadership and obsolescence in industries where technology evolves rapidly.

Quality assurance is a top priority in PCB turnkey services. Since all processes occur within a single manufacturing ecosystem, there is greater control over quality at every stage, including:

This level of quality assurance is difficult to achieve when working with multiple suppliers. Turnkey PCB manufacturing eliminates inconsistencies from using different vendors for various production stages.

A significant challenge in traditional PCB manufacturing is identifying design flaws late in the process, leading to costly revisions. Turnkey PCB manufacturing mitigates these risks by:

Many manufacturers also use advanced simulation software to predict performance issues before production begins, further reducing risks and ensuring a smooth PCB turnkey assembly process.

Managing multiple vendors can be overwhelming, leading to supply chain bottlenecks and production delays. With a turnkey manufacturing approach, businesses benefit from:

For companies requiring specialized components, a turnkey PCB manufacturing company often has preferred supplier relationships, ensuring high-quality parts are available even in cases of supply chain disruptions.

Whether you’re producing a small batch of prototypes or scaling up to high-volume PCB turnkey solutions, turnkey contract manufacturing offers flexibility. Manufacturers can quickly adjust production plans based on:

Companies can also request design modifications without the hassle of coordinating with multiple suppliers, making turnkey PCB manufacturing a more adaptable option.

The turnkey PCB assembly process is a carefully orchestrated sequence of steps, designed to transform your initial design into a fully functional product. Each phase, from design review to final packaging, is executed with precision and attention to detail, ensuring high-quality results.

The process begins with thoroughly evaluating the PCB design, including Gerber files, Bill of Materials (BOM), and assembly drawings. Engineers conduct a DFM and DFT (Design for Testing) analysis to optimize the design for manufacturability and performance.

A PCB manufacturing company procures high-quality components from reliable suppliers, ensuring they meet industry standards and the project’s specific requirements. Turnkey PCB manufacturing providers typically have well-established vendor relationships, reducing costs and lead times.

The PCB is manufactured according to specifications, including layer stack-up, material selection, and trace routing. Turnkey production providers ensure the board meets IPC-6012 standards for rigid PCBs or IPC-6013 for flexible PCBs.

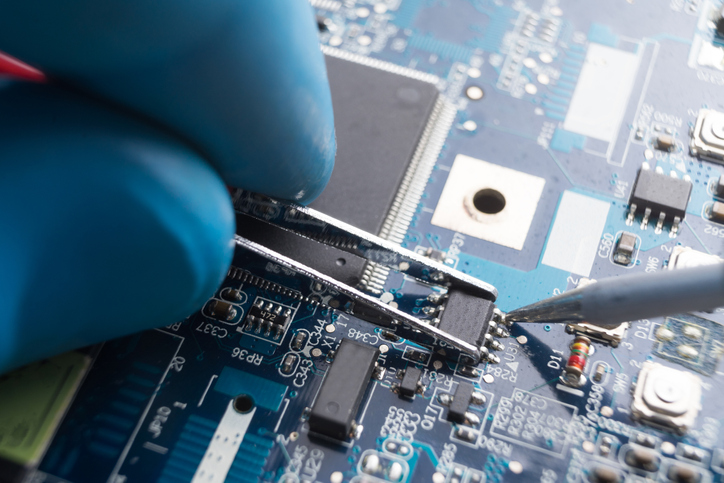

Components are placed and soldered onto the PCB using surface mount or through-hole technology. Advanced pick-and-place machines ensure precise assembly, while reflow soldering and wave soldering create secure connections.

Comprehensive testing ensures that the PCB functions correctly. This includes:

Once testing is complete, the PCBs undergo a final inspection before being packaged and shipped to the customer. Many turnkey PCB electronics providers offer customized packaging solutions to meet specific shipping and handling requirements.

Selecting a reliable PCB turnkey provider is critical for achieving high-quality, cost-effective manufacturing. Consider the following factors:

Turnkey PCB assembly isn’t just a manufacturing solution — it’s a strategic advantage. By choosing turnkey PCB assembly, you're not just selecting a service; you're also investing in a streamlined process that prioritizes efficiency, quality, and cost-effectiveness. This approach allows you to focus on innovation and product development, while a dedicated electronics manufacturing services provider manages the intricacies of PCB production.

Whether you’re scaling up for mass production or perfecting a prototype, turnkey PCB assembly offers the flexibility and reliability you need to stay ahead in the competitive tech landscape.

Ready to streamline your PCB production and bring your ideas to life faster? Explore how Matric’s manufacturing capabilities can support your next project.

Download our guide:

(Editors Note: This article was originally published in December 2019 and was updated in February 2025 to reflect current information)

Solder is what makes the electrical connections work on your printed circuit board (PCB). Solderability, then, measures how well metal is wetted by...

Electronics manufacture and testing are like squabbling siblings. PCB testing is a necessary expense that, when done correctly, prevents much larger...

1 min read

The decision on which electronics manufacturing supplier to choose can be a difficult one. The outcome of the quoting process often decides who...