Matric to Showcase Expertise at The Battery Show 2024

Join Matric atThe Battery Show 2024, a premier event for the battery and electric vehicle technology industries.

Forklifts are an integral part of any warehouse material handling operation. They enable the safe and efficient movement of goods from one location to another, allowing for more efficient storage, transport, and shipment of goods. By using forklifts in warehouse operations, businesses save time and money while increasing safety for staff members responsible for transporting items manually.

Forklift battery chargers are a crucial component in ensuring the smooth operation of your warehouse. Goods need to be stored and shipped quickly and without interruption, making it vital to maintain a reliable fleet of forklifts with a dependable source of power. By regularly maintaining your forklift battery chargers, you can increase productivity and optimize the performance of your fleet of forklifts.

Forklift chargers are an essential part of any warehouse material handling operation where forklifts are used. They provide the power necessary for the charger for a lift truck to be able to move heavy and large items throughout the warehouse.

Without a properly charged battery, the forklift will be unable to operate effectively, leading to decreased productivity and efficiency. The charger also ensures that the battery is kept in good condition over time which extends its life and ensures that it can continue to perform at its best. Proper maintenance and care of your fleet of forklifts by regularly charging their batteries will ensure maximum performance and reliability.

The battery is roughly 30% of the forklift cost. Therefore, it saves money to be proactive in proper care and maintenance. Each battery, when created, has roughly 1,500 charges before it will no longer be useful. This means a lifespan of five years, based on daily charging 300 days of the year, and with a few instances of fast charging mixed in.

The ideal window for charging a forklift battery is when there is 20-30% battery left — NOT when there’s 50-60% left. That is a waste of energy.

Batteries are also impacted by extreme temperatures, with a significant drop in performance when temperatures are above 92° F and below 30° F. However, there are batteries designed specifically for extreme temperatures, and those can maintain performance despite the extreme temps.

There are a few situations to avoid when it comes to your forklift battery, including:

When powering a forklift, there are options when it comes to batteries:

The wrong forklift battery charger can void your warranty, damage the battery, and ultimately cost you a significant amount of money when you are hoping to save. Forget about cutting a few corners, get the right charger for your forklift battery needs. It is important to match the charger voltage to the battery voltage. Also, it is key to choose a charger that helps optimize performance and keep the warehouse operations running smoothly.

Choosing the right forklift charger depends on various factors, including:

When considering the best forklift charger, it is important to assess your warehouse needs, including the size of your forklift fleet and the types of forklifts and batteries you keep on hand. It is also a good idea to take into account the charging rate needed for each battery, operational hours at your location, and the shifts your forklifts are used for, as well as the general energy consumption patterns for your facility.

When it comes to charging forklift batteries, processes and things to watch for differ based on the type of battery you rely on for power.

In terms of proper handling and storage of lead-acid batteries, the following are recommended safety precautions during charging:

Emergency Procedures and Protocols:

Lithium-ion batteries have a reduced level of maintenance without a need for water in the battery. However, that does not mean that the batteries can be trusted to maintain optimal performance without regular maintenance checks.

Maintenance concerns for Lithium-Ion Batteries include:

The integral role of forklift chargers in optimizing warehouse efficiency

Importance of selecting the right charger for your specific operational needs

Embracing innovative technologies for a more productive and sustainable future

Matric staff are prepped to outline the key components of unmanned vehicle charging — and the considerations to address first. Contact Matric today to get the ball rolling for better clarity on your warehouse charging needs.

Join Matric atThe Battery Show 2024, a premier event for the battery and electric vehicle technology industries.

An electric vehicle battery management system (BMS) is essential to keeping an EV running safely and reliably. It helps protect the battery and...

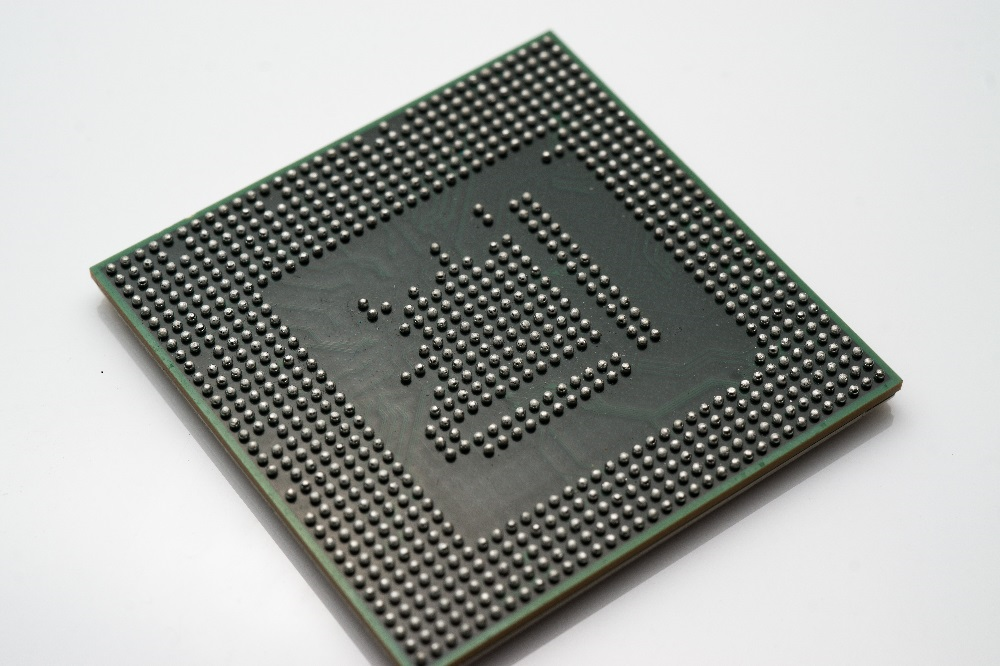

Ball grid arrays are a form of high-density, low-cost packaging in the PCB industry.