All About MSHA (Mine Safety and Health Administration) Regulations

Just about any piece of electronics can be dangerous when they’re manufactured poorly. But when you’re manufacturing for the mining industry, you’re...

2 min read

Matric Group

:

Jul 16, 2020

Matric Group

:

Jul 16, 2020

In ordinary environments, these sparks are no threat to the people using the equipment. However, in areas filled with explosive gases and dust, these sparks can be a serious hazard. Under these circumstances, electrical equipment can only be used if special safety measures are put in place.

Electrical devices that are safe to use in hazardous, potentially explosive environments are called intrinsically safe. These devices are made using different methods, including explosion-proof, flame-proof, or intrinsic safety. .

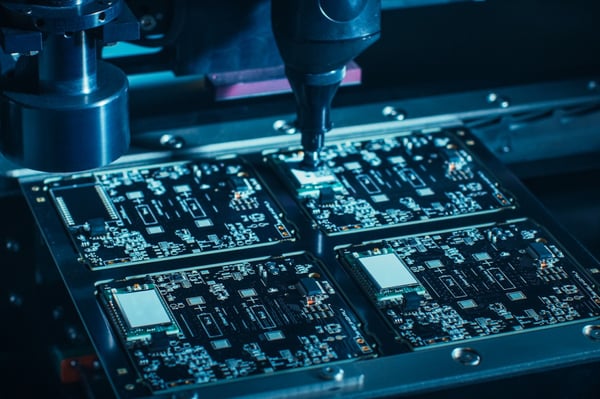

To make intrinsically safe components, electronics manufacturers must:

Here’s everything you need to know about intrinsically safe electrical device manufacturing.

Intrinsically safe products are explosion-proof because they limit the energy available, preventing ignition. Essentially, they're spark-proof. Intrinsically safe equipment in mines and petrochemical refineries are a necessity to protect both the employees and the community.

Several different agencies maintain the standards for intrinsic safety, like Underwriters Laboratories. Intrinsically safe design guidelines are strict, as they should be.

A good starting point for meeting intrinsically safe guidelines is to first check and make sure the product also meets RoHs compliance standards and IPC-6011 standards.

If an unsafe PCB is used in a hazardous environment, gases, fibers, fillings, vapors and dust in the air may ignite, potentially leading to explosions, injuries, and deaths.

There are many environments where unsafe PCBs can’t be used, including:

In all of these environments and more, unsafe PCBs can cause catastrophic accidents. Abiding by intrinsically safe design guidelines will lessen workplace danger.

Generally speaking, the best way to produce an intrinsically safe product is to follow intrinsically safe guidelines from an agency like UL, MSHA, ATEX, and others. There are many things that engineers can proactively do to comply with intrinsic safety standards and improve the safety of their designs. Below are a few methods that electronics OEMs use to ensure their products are safe.

Try splitting the power in a device into multiple circuits. This enables the electronics manufacturer to maximize the amount of power in an electrical device without putting too much power in a single circuit.

Enhanced voltage levels must be protected with voltage limiters. If not, the PCB may spark, running the risk of ignition.

When choosing batteries, like high-density, lithium-ion batteries, make sure they can withstand the conditions of their end-use environment. In addition, it's important to minimize the electrolyte leakage that occurs when a severe short-circuit occurs.

Components that run the risk of creating heat or sparks, such as fuses, need to be covered in a sealant, usually room temperature vulcanizing silicone (RTV). Sometimes, when coating a component, little pinholes or cavities can appear in the RTV, which need to be corrected to ensure a fire-safe design.

The enclosures engineers choose for their electronic equipment goes a long way toward protecting their PCBs. The proper design and material prevents the electrical circuit from exposure to flammable environments.

Intrinsically safe products must pass stringent qualification guidelines, which can be a lot to manage. Partnering with an experienced EMS can lessen the impact when it comes to intrinsically safe design guidelines.

Another important aspect of manufacturing PCBs that are up to code is testing. It’s better to test twice, sell once rather than have faulty components come back. Learn more about PCB testing with our free downloadable guide.

Just about any piece of electronics can be dangerous when they’re manufactured poorly. But when you’re manufacturing for the mining industry, you’re...

When reliable performance matters – whether in medical devices or handheld mining tools – every component in your design needs to contribute to...

For those in the electronics manufacturing supply chain, RoHS compliance is a big deal. Hopefully you’ve treated it as such well in advance of the ...