INFOGRAPHIC: Conformal Coatings vs. Potting/Encapsulation

The electronics sector is one of the most dynamic industries, with virtually unlimited applications. This is why its growth is expected to remain...

4 min read

Matric Group

:

Apr 27, 2023

Matric Group

:

Apr 27, 2023

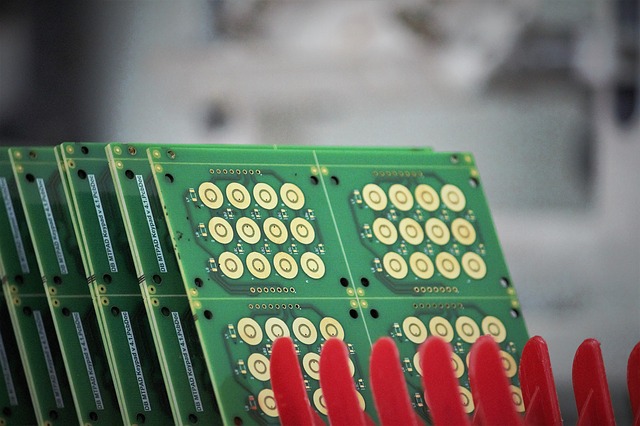

With the rise of IoT and technology in general, electronics are featured in many environments, exposing delicate electronic connections to potential hazards like extreme temperatures, moisture, and dust. These factors can damage components and compromise the assembly’s integrity.

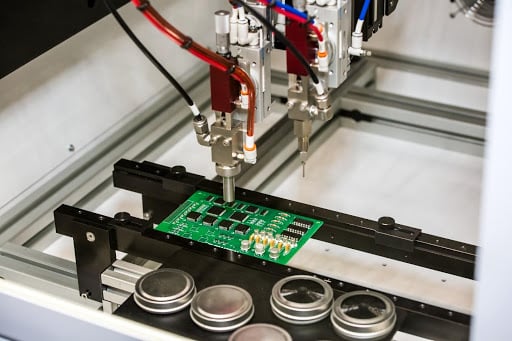

A proactive measure to safeguard your electronic assembly is the use of conformal coating during the printed circuit board (PCB) production process. This technique involves applying a thin, transparent film that adheres to the circuit board’s shape, shielding its components from harm.

When designing a PCB for potentially challenging environments, it’s crucial to determine if a conformal coating is suitable for your application. If so, you’ll need to evaluate the different types of conformal coatings available and select the most appropriate application method.

With that in mind, let’s delve into the various conformal coating options at your disposal:

As we explore the world of conformal coatings for PCB protection, it’s essential to understand the variety of options available. Each type of conformal coating offers unique characteristics, benefits, and potential drawbacks, making them suitable for different applications and environmental conditions.

Popular methods of PCB conformal coating include:

A simple application method, this is best for low-volume production, rework, and repair.

Brush coating is done by hand and tends to be thicker and less cosmetically appealing. This option is best for those without the tools to utilize other options or when working on a few boards at a time.

This method involves using an aerosol spray to apply the coating. Also better for lower-volume production, spraying can be time-consuming because all areas that don’t require coating need to be masked.

This method provides a superior surface finish and is cost-effective, but doesn’t offer deep board penetration.

“Dipping” involves submerging the board in a coating solution, then withdrawing it.

Good for high-volume production, this method is fast, accurate, and completely penetrates the board, coating the entirety of the assembly. However, masking must be perfect to avoid leakage, making many boards unsuitable due to design. Only boards that accept coating on both sides can be subject to this method.

This strategy uses automated robotic spray nozzles to apply conformal coating to specific assembly areas.

Another high-volume method, selective coating is fast and accurate and applies the coating directly to the areas of the board where it is required, eliminating the need for masking.

You must design your circuit board to be compatible with selective coating.

As we continue to dive into the realm of conformal coatings for PCB protection, it’s important to familiarize yourself with the diverse materials employed in the process. This knowledge can help you decide what material to select for safeguarding your electronic assemblies.

Conformal coating materials include:

| Pros | Cons |

| Easy rework | Difficult to maintain viscosity |

| Easy drying process | Flammable |

| Good humidity resistance | High probability of reversion under temperature and humidity stress |

| High fluorescence level | |

| Ease of viscosity adjustment |

| Pros | Cons |

| Useful to around 150fC [302fF] | Higher chloride contamination potential |

| High chemical and abrasion resistance | Process intensive, difficult to maintain viscosity |

| CTE closer to epoxy PCB substrate | Complex mix ratios |

| Good dielectric properties | Potential for high stress during temperature cycling conditions |

| Good humidity resistance | Difficult to rework and remove |

| High probability of reversion under temperature and humidity stress | |

| Lacks flexibility |

| Pros | Cons |

| Good dielectric properties | Difficult to maintain viscosity |

| Good moisture resistance | Flammable |

| Solvent-resistant | High probability of revision under temperature and humidity stress |

| Less reversion potential | Health and safety concerns |

| Abrasion-resistant | Potential for high stress during cycling conditions |

| Pros | Cons |

| High dielectric strength | Short pot life |

| Fair moisture and abrasion resistance | Does not protect against solvents or solvent vapors |

| Good moisture, humidity, and UV/sunlight resistance | If proper housekeeping is not followed, there is a potential for cross contamination |

| Low surface energy to enable effective penetration under components | Requires humidity (minimum 20% RH) to cure and only intermittent solvent resistance |

| Flexible, provides dampening and impact protection | |

| Stable over wide temperature range (in general, -40fC to 200fC) [104fF to 392fF] |

| Pros | Cons |

| Minimal added mass and low outgassing | Cannot be doped |

| Low environmental impact process | Masking required for no-coat areas |

| Biocompatibility allows use in medical applications | Parts are processed in batches in a vacuum chamber, not an in-line process |

| Excellent uniformity regardless of part geometry, no pinholes, fillets, or bridging | Coating removal and rework generally requires specific equipment, abrasion/microblasting most common technique |

| Chemical intertness/barrier properties -- insoluble in organic solvents, acids, or bases with very low permeability rates | Limited UV resistance and operating temperature limit, around 120fC [248fF] in the presence of oxygen |

| Pros | Cons |

| Low dielectric constant | Requires special liquids for polymer swelling |

| High glass temperature | Limited solubility which limits film thickness |

| Low surface energy | May require glass temperature annealing |

| Low water sorption | Requires special surface treatment for greatest adhesion |

| Good solvent, oil, and common acid resistance | Poor resistance to some acids and alkalines |

| Pros | Cons |

| Low dielectric constant, 2.28 | Parts are processed in batches in a vacuum chamber, not an in-line process |

| Low environmental impact process | Masking required for no-coat areas |

| High temperature stability (450fC) [842fF], and increased UV stability | The coating is deposited at a rate slower than the conventional poly-para-xylenes |

| Chemical intertness/barrier properties -- insoluble in organic solvents, acids, or bases with very low permeability rates | Coating removal and rework general requires specific equipment, abrasion/microblasing most common technique |

| Excellent uniformity regardless of part geometry, no pinholes, fillets, or bridging | Requires special deposition equipment different than that for the C, D, and N poly-para-xylene varieties |

Now that we’ve discussed conformal coating, you might be wondering the difference between conformal coating vs. encapsulation. Although both conformal coating and encapsulation aim to shield electronic components, they differ in various aspects, including their application, properties, and suitability for certain conditions.

Also known as potting, encapsulation involves fully encasing PCB or specific components into a thick layer of protective resin, providing a barrier against moisture, dust, chemicals, extreme temperatures, vibrations, and shock.

Encapsulation offers several benefits, including enhanced electrical insulation, vibration resistance, and protection against external factors. However, it also adds weight and bulk to the assembly, and once the PCB is encapsulated, it becomes difficult or nearly impossible to access or repair the components without causing damage to the board.

The right conformal coating will vary depending on the application of your PCBs. Deciding which coating can use can be a challenge, an electronic contract manufacturer can help you determine the best option for coating your board.

Don't forget to check out our free guide to SMD resistor and capacitor sizes!

Editor's Note: This article was first published in 2019 and has since been updated.

The electronics sector is one of the most dynamic industries, with virtually unlimited applications. This is why its growth is expected to remain...

When outsourcing your printed circuit board (PCB), electronics box build, or cable assembly to an electronics contract manufacturer, you expect a...

Box build assembly. Systems integration. Top level assembly.