Capabilities of an Electronic Manufacturing Services Company

Consolidating services is a great way to reduce costs, lead times, & confusion. Unfortunately, most electronics contract manufacturers (ECMs) don’t...

6 min read

Matric Group

:

Mar 21, 2025

Matric Group

:

Mar 21, 2025

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must function flawlessly — and that’s before your product even reaches your customers.

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must function flawlessly — and that’s before your product even reaches your customers.

That’s where an electronics contract manufacturing company becomes invaluable. Whether you’re an original equipment manufacturer (OEM) looking to scale production or need specialized expertise, the right electronic manufacturing services provider helps design, build, and deliver high-quality electronic assemblies with confidence.

These companies do far more than assemble components. They serve as an extension of your team — offering design support, precision manufacturing, rigorous testing, and even aftermarket services that keep your products performing long after they’ve shipped.

Let’s break down what to expect when partnering with an electronics contract manufacturing company, the services they provide, and why choosing the right partner is critical to your product’s success:

Electronic manufacturing services cover the full spectrum of product development and production for electronic assemblies. These services vary by supplier, but a qualified electronic products manufacturer should offer:

Whether your project is a complex industrial control system or a consumer device, working with an EMS contract manufacturer provides flexibility and expert guidance through every stage of production.

Here’s a closer look at what electronics contract manufacturers do:

A skilled electronics contract manufacturing company helps turn your product concept into a manufacturable, high-performing design. From PCB layout to custom enclosures, engineering support ensures your product meets functional, cost, and quality goals.

Top EMS partners also advise on materials — from stainless steel and aluminum to injection-molded plastics — to create durable, well-designed housings that complement your electronics.

Services include:

Selecting the right electronics contract manufacturing company means looking beyond capabilities and evaluating their commitment to quality and compliance. Industry certifications ensure your EMS partner meets rigorous standards for safety, reliability, and regulatory requirements.

Common certifications to look for include:

Common certifications to look for include:

A well-certified EMS partner minimizes risk, prevents costly delays, and protects your product’s integrity — from design through production.

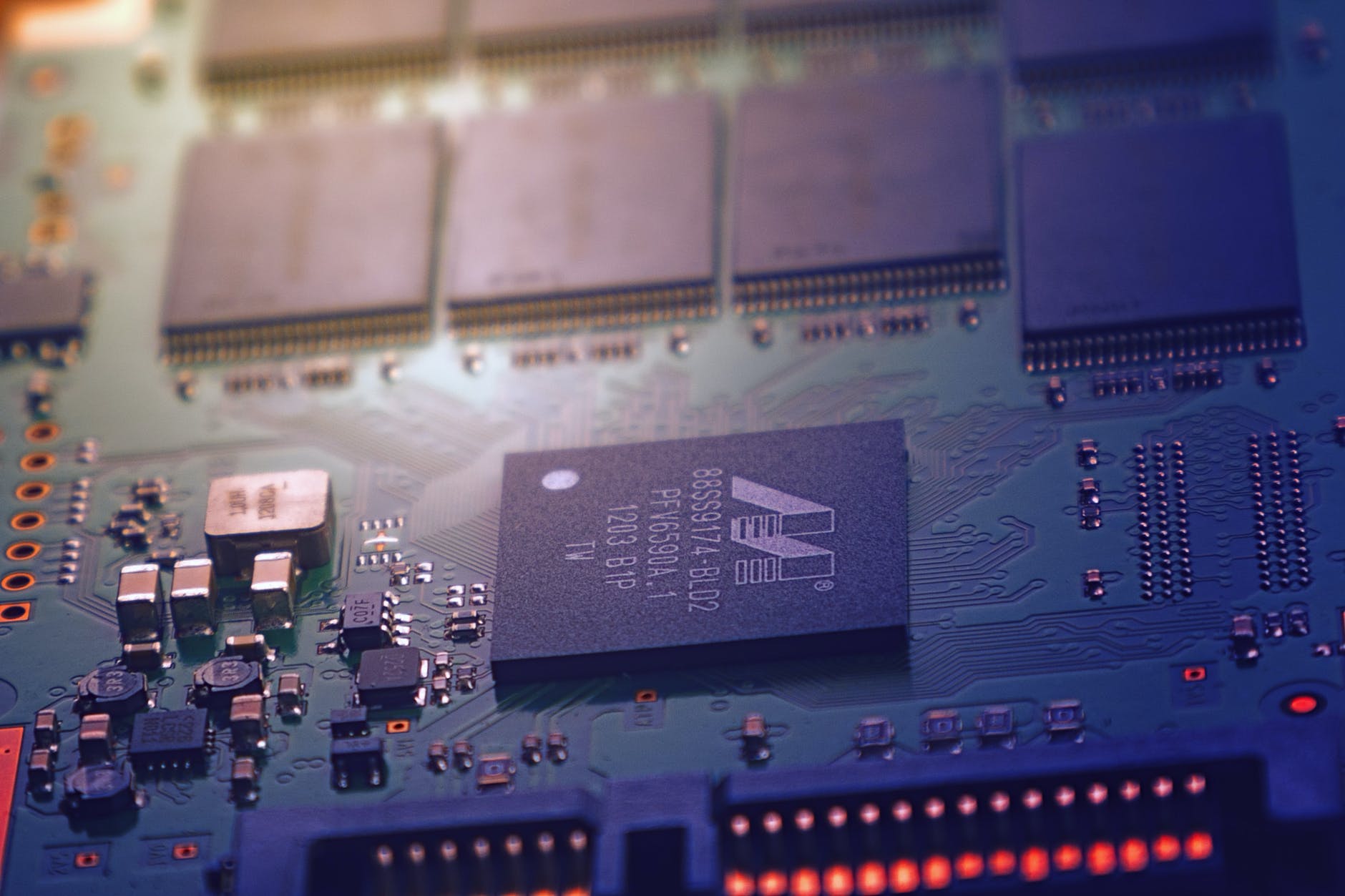

Printed circuit board (PCB) assembly involves soldering components like transistors, resistors, and integrated circuits onto a bare board using either surface mount technology (SMT) or through-hole technology. SMT is the industry standard for modern electronics, offering greater precision and efficiency, while through-hole is still used for components requiring extra durability.

Many electronics contract manufacturing companies also specialize in upgrading older through-hole designs to SMT, extending product lifespan and improving performance. Advanced EMS providers integrate state-of-the-art machinery for increased speed, accuracy, and reliability.

To ensure quality and functionality, a complete EMS partner will offer in-house testing services — verifying that every assembled PCB meets performance and compliance standards.

A full-service electronics contract manufacturing company should provide custom cable assembly and mechanical subassembly services, essential for industries like mining, medical, instrumentation, and industrial controls where reliability is critical.

Experienced EMS providers can engineer, build, and test a wide range of assemblies, including:

Manufacturing often involves precision hand soldering, so it’s important to work with a vendor certified to IPC standards. Many EMS providers also offer injection over-molding, creating rugged assemblies protected from environmental hazards. Over-molding enhances durability by encasing components in materials designed to resist moisture, chemicals, and abrasion — ideal for demanding applications.

Cable assemblies should undergo functional and pull testing to ensure performance and durability. Testing services may include:

These tests confirm that each assembly meets performance requirements and is ready for real-world use.

A full-service electronics contract manufacturing company offers electromechanical assembly services — commonly known as box builds — to support complex product integration. These assemblies house electronic components within durable enclosures made from materials such as:

An experienced electronic manufacturing services provider ensures every assembly meets functional and environmental demands, often supported by a dedicated final assembly team.

Electromechanical services may also include:

Potting involves filling assemblies with protective compounds to enhance durability. Heat shrink tubing adds a vital layer of insulation — essential for electronics used in harsh or hazardous settings like mining or industrial facilities.

All electromechanical assembly is performed with intrinsic safety in mind, protecting product integrity and end-user safety from the design phase through production.

Partnering with an experienced electronics contract manufacturing company gives you access to specialized design and engineering expertise — even if you don’t have those resources in-house. A capable EMS partner can assist at any stage of development, or take the lead from concept to production.

Design services often include:

The right partner also helps with costing exercises, identifying alternative materials or components that reduce costs without compromising quality — a valuable resource when navigating supply chain challenges.

Comprehensive contract design support ensures your product is fully optimized for performance, production, and regulatory approval — ready for a smooth transition to manufacturing.

Reliable testing is critical to electronic assembly manufacturing, protecting your product, supply chain, and reputation. Before a shipment leaves the facility, your electronics contract manufacturing company should verify every PCB assembly meets your specifications and performance requirements.

Skipping or minimizing testing can lead to:

A capable EMS partner offers a full range of PCB testing services, from basic inspections to advanced functional testing, including:

Comprehensive testing confirms your assemblies are fully functional and ready for the next phase — saving you time, money, and frustration. Learn how:

Bringing a new electronic product to market without proper prototyping can be costly. PCB prototyping allows you to test and refine your design before committing to full production, minimizing risks and unexpected expenses.

Prototyping serves several key purposes:

Typical PCB prototyping stages include:

A reliable electronics contract manufacturing company supports your product long after it leaves the production floor. Comprehensive aftermarket services help extend product life, maintain performance, and protect your investment — keeping your supply chain moving and your customers satisfied.

When evaluating an EMS partner’s aftermarket capabilities, look for experience, technical expertise, and the right equipment to handle complex repairs and upgrades. A strong partner should offer:

An experienced EMS partner can service the products they manufacture and third-party and legacy equipment, even suggesting design improvements if repeated failures are identified. This proactive support helps prevent downtime, improves reliability, and keeps your products performing at their best.

Component obsolescence is a growing challenge in electronics manufacturing. As parts reach the end of their lifecycle, OEMs risk supply chain disruptions, redesigns, or production delays. A knowledgeable electronics contract manufacturing company helps mitigate these risks with proactive obsolescence management strategies.

An experienced electronic manufacturing services provider will monitor component availability and provide timely recommendations, such as:

An experienced electronic manufacturing services provider will monitor component availability and provide timely recommendations, such as:

To support long-term product success, EMS contract manufacturers should offer life-cycle analysis — evaluating environmental impact, supply chain stability, and component availability. This process helps identify potential risks early, enabling the selection of alternative components or redesigns before production begins.

Effective obsolescence management doesn’t just protect your product after launch — it ensures that supply chain stability and product support are baked into your design and manufacturing processes from the start.

Outsourcing to an electronics contract manufacturing company offers a range of benefits:

At Matric Group, we help OEMs bring their products to market with full-service electronic manufacturing services — from design and prototyping to assembly, testing, and aftermarket support. Backed by decades of experience and industry certifications, we’re ready to be your long-term manufacturing partner.

Contact us today to learn how we can support your next project.

(Editor's note: This article was originally published in May 2018 and was updated in March 2025 to reflect updated and current information)

Consolidating services is a great way to reduce costs, lead times, & confusion. Unfortunately, most electronics contract manufacturers (ECMs) don’t...

“How will my idea go from conception to finished product at your company?” It’s a question we hear a lot, and a good one. It’s natural to want to...

So, you’ve made the choice to design a custom PCB for your design. Instead of buying off the shelf electronics.. but what’s next?