3 min read

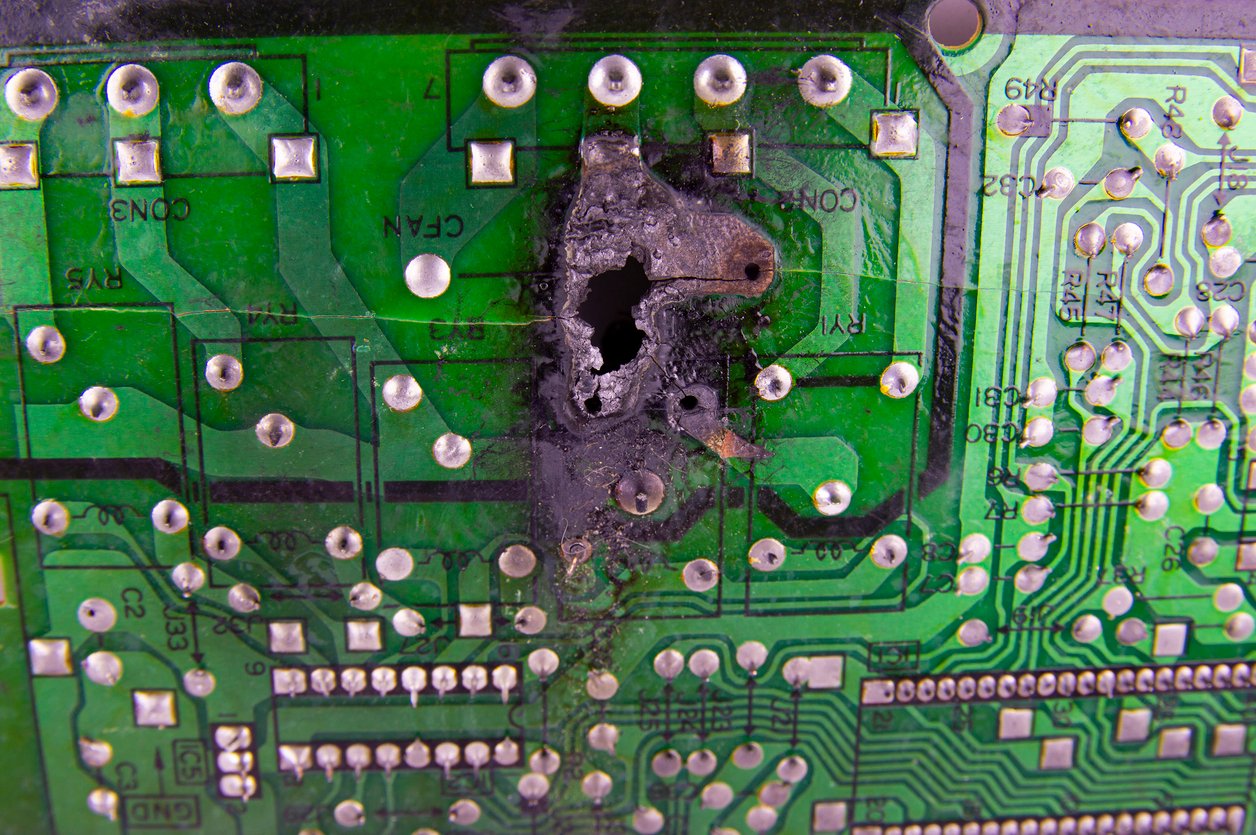

Industrial PCB Repair, Remanufacture, or Redesign? How to Decide

OEMs often rely on electronic products and systems that remain in service for many years. Over time, however, these systems can become increasingly...

3 min read

OEMs often rely on electronic products and systems that remain in service for many years. Over time, however, these systems can become increasingly...

6 min read

When you order printed circuit boards, you already understand the costly consequences of failure. The last thing you need is for your PCBs to...

2 min read

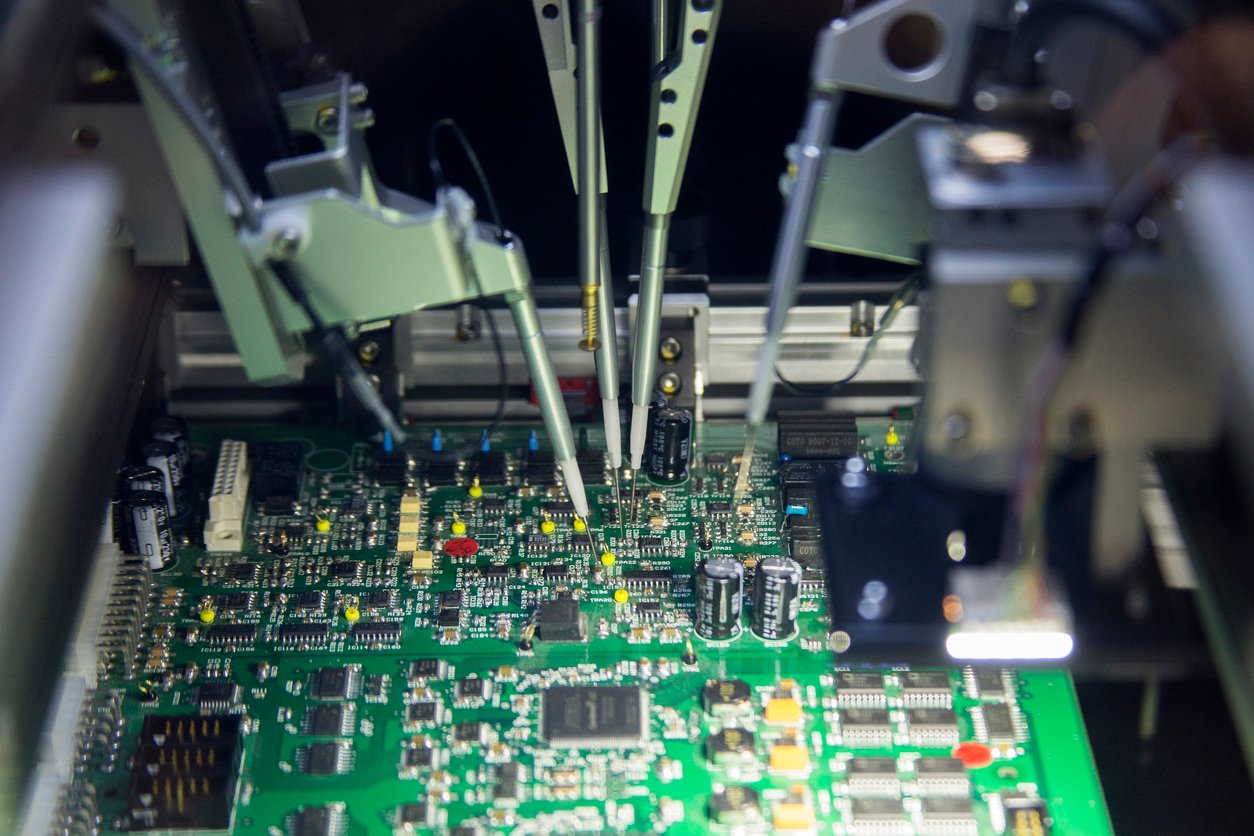

Testing and inspection are vital parts of electronics contract manufacturing, for obvious reasons. Before that shipment of PCBs arrives on your...

2 min read

Solder is what makes the electrical connections work on your printed circuit board (PCB). Solderability, then, measures how well metal is wetted by...

3 min read

PCB contamination testing is not for every project, but it’s a lifesaver for some.

4 min read

Printed circuit boards (PCBs) are the foundation of almost every electronic product. When one fails, the results can include product recalls, costly...

4 min read

PCB design can be challenging. The complexity of your project and the potential consequences of PCB failure may require thorough, high-level testing...

6 min read

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

5 min read

The electronics manufacturing supply chain is a major risk for many OEMs. Challenges in this area include environmental and global regulations, which...

6 min read

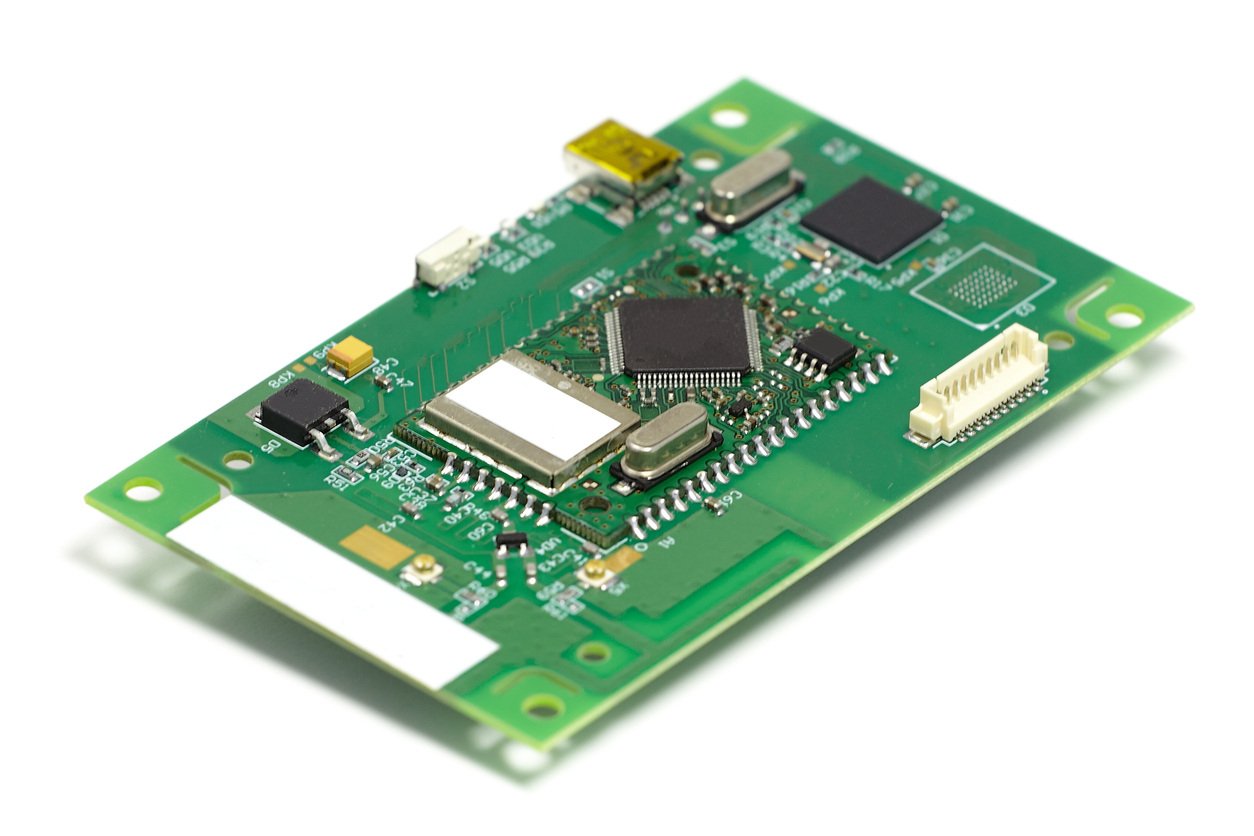

Want to get smaller, lighter, or more powerful? (Who doesn’t?) In electronics, customers are demanding all three – at the same time. It might seem...

3 min read

In the demanding field of printed circuit board (PCB) fabrication and manufacturing, closely adhering to industry standards is crucial for an OEM's...

2 min read

(Photo courtesy U.S. Air Force) Electromechanical PCB box build assembly services are one of the most important offerings of electronics contract...

2 min read

A first article inspection for electronics products is a verification process that documents and certifies the accuracy of each and every facet of...

3 min read

Deciding on the best testing method for your printed circuit board can be a daunting task. There are plenty of factors to take into consideration,...

3 min read

The adage “If it’s not broken, don’t fix it” holds no ground in the realm of public transportation, mining equipment, and numerous other high-stakes...

3 min read

In 2006, the European Union rolled out a directive restricting the use of certain hazardous chemicals. This directive, Restriction of Hazardous...

4 min read

Printed circuit board (PCB) manufacturing is a process that requires precision and reliability. As technology advances, laptops and smartphones are...

4 min read

If there's one thing that takes center stage in the aerospace industry, it's safety. This, of course, comes hand in hand with high-quality components.

4 min read

Today a growing number of original equipment manufacturers (OEMs) outsource some of their work to electronics contract manufacturers (ECMs). The ECMs...

5 min read

“How will my idea go from conception to finished product at your company?” It’s a question we hear a lot, and a good one. It’s natural to want to...

2 min read

The IPC standards chart (or tree, in some circles) provides guidelines for the production and assembly requirements of electronics manufacturing...

3 min read

Massive amounts of money are at play when it comes to power distribution electronics. The electronic product development life cycle frequently sparks...

4 min read

Just about any piece of electronics can be dangerous when they’re manufactured poorly. But when you’re manufacturing for the mining industry, you’re...

6 min read

There are many areas in life where accepting mistakes as inevitable is a good thing -- electronics manufacturing is not one of them. The end goal...