How Much Does a PCB Prototype Cost?

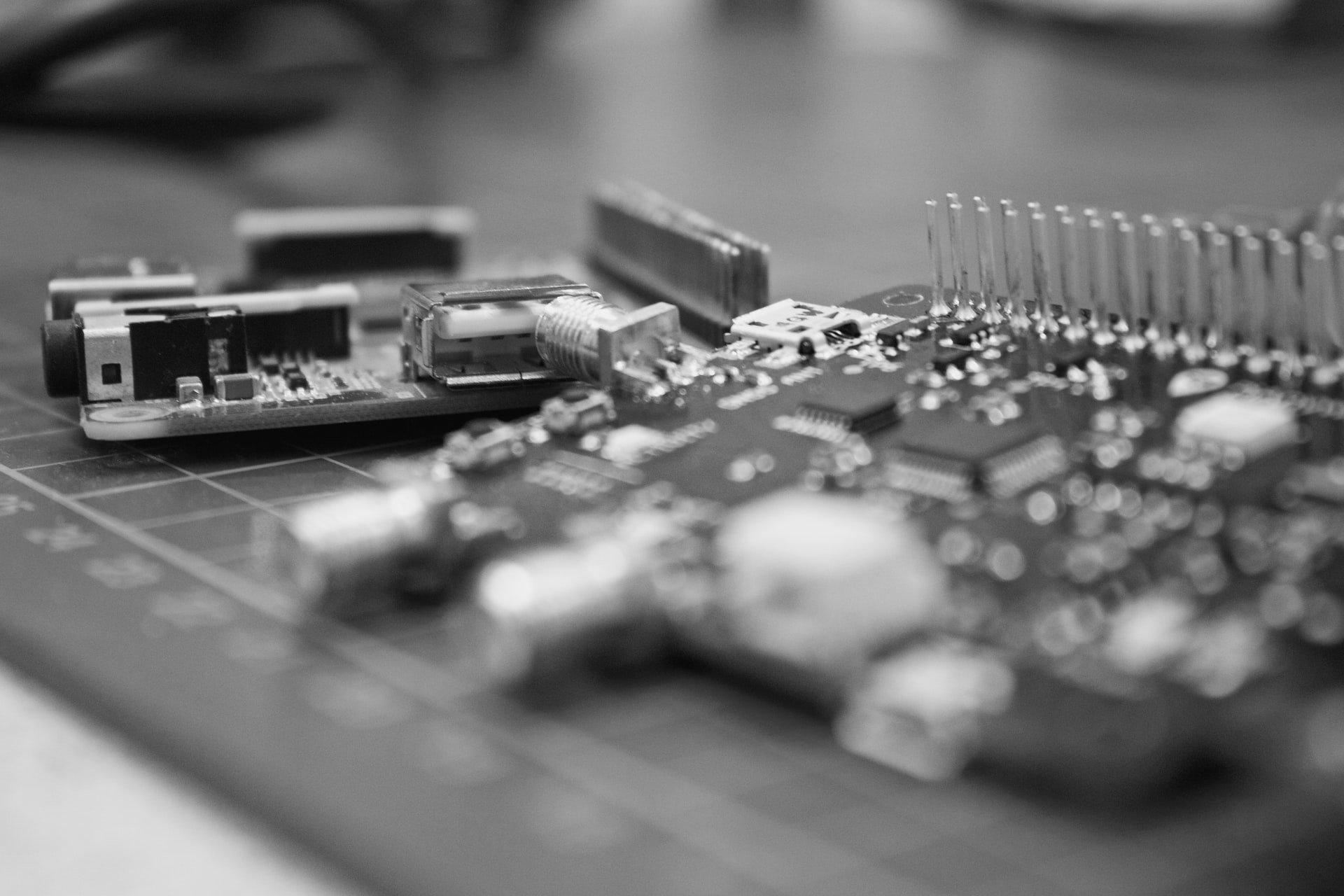

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

Prototyping is just as important to the electronics manufacturing process as designing, engineering, and testing. Ignore it at your own risk.

Original equipment manufacturers (OEMs) prototype by necessity because it tells you whether your design is truly ready to move forward into production.

While you may find yourself wondering if prototyping is something you really have to do, in most cases you definitely want to prototype, and here’s why:

There are a few situations where electronics contract manufacturers (ECMs) don’t prototype PCB assembly jobs -- such as really low-volume orders or simple designs. In all other cases, we encourage prototyping.

When you don’t prototype, you run various risks, including:

All of these situations will stretch out your lead time and production costs.

No matter how confident you are in your concept, you can never be certain it’ll do what you expect until you prove it in real life. With many new and innovative designs, it’s impossible to know what the outcome is going to be until you put all the pieces together.

You may have a design that needs to stick very closely to your specifications. Using a PCB prototype assembly service should show you that the contract engineering team did exactly what you asked.

If it fails from there, it’s your design to blame.

With many products, you are facing a variety of regulatory hurdles. Prototyping is the first step to getting past all those obstacles and moving on to testing.

Keep in mind that prototyping is only a single step to get to actual testing. It doesn’t guarantee that the product will work on the market. There are other tests to determine that. But prototyping is still an important step toward clearing your product with the FCC, UL, or whatever agency you’re dealing with.

There are so many things that can go wrong with a design, even one that looked lovely in CAD software.

For example, the battery life for the product might not be what you’d hoped for. At the prototyping stage, you have time to go back and fix the issue. Prototyping ensures you only make a few duds, instead of 100s or 1,000s.

No matter how amazing the concept, it still needs to be manufacturable. Prototyping gives the production department assurance that there are no issues that will make manufacturing impossible, or so expensive that it is unfeasible. Common issues include:

Typically, software for your electronics can be started using evaluation boards. PCB prototypes are necessary to complete the software and test all the unique electronic hardware designed on your board.

It’s impossible to give a specific price for prototyping because the amount of work involved varies greatly by the complexity of your project. The more complex it is, the more costly prototyping becomes.

Regardless of the cost of prototyping, it’s a drop in the bucket compared to locking up the market share with your awesome new product.

To recap, the greatest benefits of prototyping a PCB assembly are:

Prototyping isn’t reserved for high-tech vehicles or revolutionary consumer gadgets. It’s also a great practice for manufacturing printed circuit...

In an ideal world, getting a quote for prototype production from your electronics contract manufacturer (ECM) would go smoothly and quickly. But the...

The adage “If it’s not broken, don’t fix it” holds no ground in the realm of public transportation, mining equipment, and numerous other high-stakes...