3 min read

Extending Legacy Products with PCB Reverse Engineering

Legacy electronic systems often remain in service far longer than originally expected. Industrial controls, medical equipment, transportation...

3 min read

Legacy electronic systems often remain in service far longer than originally expected. Industrial controls, medical equipment, transportation...

2 min read

Let’s face it, soldering can be a challenging task. Even with years of training and the most advanced machinery, PCB soldering defects are sometimes...

4 min read

Printed circuit boards (PCBs) are the foundation of almost every electronic product. When one fails, the results can include product recalls, costly...

6 min read

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

4 min read

When reliable performance matters – whether in medical devices or handheld mining tools – every component in your design needs to contribute to...

3 min read

Working with small circuit board areas can increase the risk of various PCB defects, tombstoning in particular. While the grim nature of “tombstone”...

5 min read

Driven largely by technological advancements and the increasing demand for efficient trading solutions, the financial technology landscape is...

6 min read

Want to get smaller, lighter, or more powerful? (Who doesn’t?) In electronics, customers are demanding all three – at the same time. It might seem...

5 min read

OEM circuit boards are fundamental components in a wide range of consumer and commercial applications, from automobiles to household appliances and...

5 min read

Printed circuit boards (PCBs) have been instrumental in the rapid advancement of technology since their introduction in the 1940s. PCBs...

4 min read

PCBs are crucial to modern financial systems and play a critical role in the infrastructure that supports the global financial ecosystem. These...

2 min read

PCBs have been getting smaller for the past few decades, and few industries have taken more advantage of that than the medical industry. While that’s...

3 min read

Medical device companies looking for a PCB design and assembly partner have many important factors to consider, all with the end user’s well-being at...

3 min read

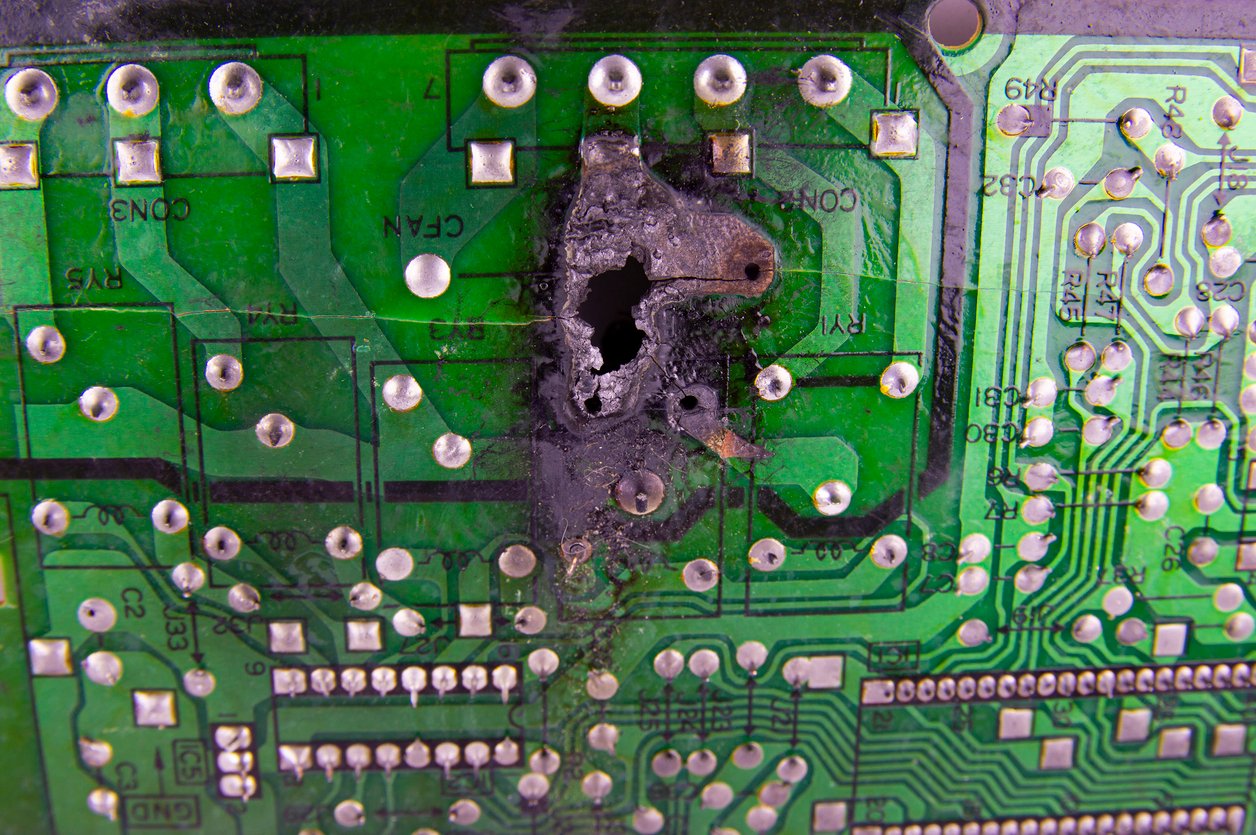

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...

2 min read

The Design-2-Part show for the Greater New York area will be held April 26-27 in Secaucus, NJ.

4 min read

Consolidating services is a great way to reduce costs, lead times, & confusion. Unfortunately, most electronics contract manufacturers (ECMs) don’t...

3 min read

At this point, we’re all familiar with light-emitting diode (LED) lights. From the bright, efficient bulbs replacing the old filament lamps, to the...

5 min read

“How will my idea go from conception to finished product at your company?” It’s a question we hear a lot, and a good one. It’s natural to want to...

4 min read

When designing solar-powered embedded systems intended for outdoor applications, durability, performance, and energy efficiency are a perfect storm...

4 min read

More opportunity, more money … and more problems.

4 min read

The benefits of new technologies in health care are awesome. Developers are showing off some amazing ideas for medical devices. It’s no surprise that...

6 min read

There are many areas in life where accepting mistakes as inevitable is a good thing -- electronics manufacturing is not one of them. The end goal...

3 min read

Optimizing PCB layout design for manufacturability is one of the most crucial aspects of your product’s development process. Key decisions made...

2 min read

Whether you’re in the electronics, healthcare, or manufacturing industry, it’s easy to get overwhelmed by the hodgepodge of standards regarding PCB...