The Cost of PCB Repair Services Vs. E-Wasting Your Budget

Plastic waste may snag all of the headlines, but it's not the only type of waste overwhelming landfills and contaminating soil and water.

3 min read

Matric Group

:

Dec 08, 2025

Matric Group

:

Dec 08, 2025

There’s no perfect playbook to establishing and maintaining major transportation projects like subways, bus systems, and other transit developments.

There’s no perfect playbook to establishing and maintaining major transportation projects like subways, bus systems, and other transit developments.

One potential problem to consider before the first train leaves the station is the inherent limit of the electronics you use. No matter how well you build them, they will wear out and they will become obsolete. Long-term projects like these mean you have to think about the replacements long before the original system is retired.

Where you can get a few significant wins is with advanced electronics remanufacturing and PCB repair services. Extending the lifespan of your current PCB assembly is almost always more cost-efficient than nuking your legacy design and starting all over.

Partnering with an electronics remanufacturing company from the beginning can help you be proactive. Here are seven ways a contractor can help you identify issues and stay ahead of the curve:

Do the electronics you make for the transportation industry need to last a decade or two -- or more? If any of the issues below sound like your company, you may need to team with a new (or better) electronics manufacturer.

There’s the bad news. Now let’s get to the good news -- the transportation industry is a perfect fit for aftermarket electronic services.

Here’s your ticket to long-term design success with the right electronics contract manufacturer (ECM):

A skilled PCB refurbishment company should have multiple tricks up its sleeves for managing inventory. We recommend partnering with a contractor that uses third-party component database software like SiliconExpert.

An electronics contract manufacturer can offer you an NCNR (non-cancelable, non-returnable) order so you can partner with the ECM on the investment in components. The contractor may also be able to maintain a set level of inventory on its own.

PCB repair techniques and other aftermarket services keep electronics working as intended for years.

By having repairs done along the product’s lifetime, you can keep designs consistent. You won’t risk needing to get further certifications – which can be time-consuming and costly -- and can keep maintenance quick and easy.

“Remanufacturing” can mean a lot of things. Some aftermarket electronics refurbishment companies do them all:

All of these come up at one point or another in transportation electronics. An aftermarket services partner should prove capable of keeping your people-movings running smoothly, no matter the method needed.

Your options for making major improvements to a transportation system are limited to the funding available. Until you get your next round of funding, you need to love the one you’ve got.

PCB board repair and other repair services can help you achieve that goal, stretching out your budget far more effectively than a total rebuild.

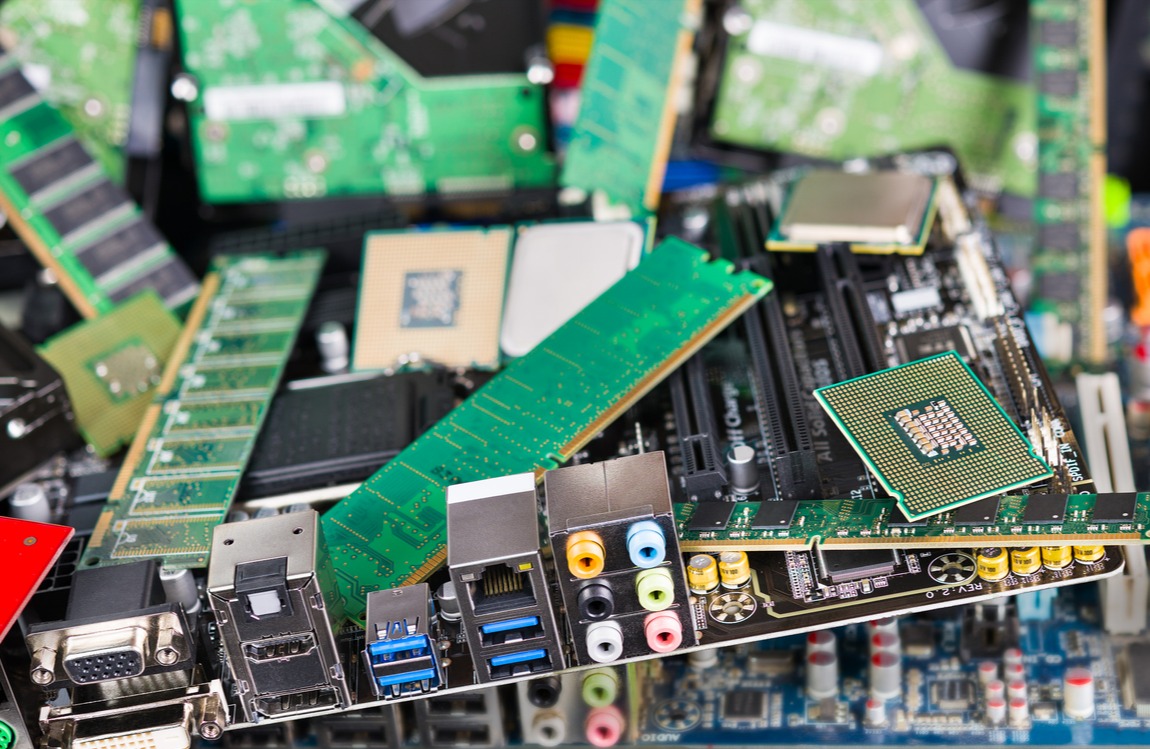

The more you repair, the less you throw away.

PCB troubleshooting is usually capable of identifying a solution that involves switching out as few components as possible. Some electronics manufacturers offer PCB testing services not only for new products, but existing ones as well.

Downtime is a killer for the transportation electronics industry. PCB calibration, refurbishing, and the like are the easiest way to minimize disruption of your service.

A good electronics remanufacturing partner is responsive, keeps the communication lines open, and understands the urgency of your situation.

A reputable remanufacturer and repair specialist may offer other services you don’t even know about yet.

Check with a potential remanufacturing partner to see if it also offers:

With the right arrangement, you can consolidate lead times and cut delivery/transportation costs by using single-source manufacturing.

Too many transit agencies miss out on real savings by using PCB aftermarket services only after a failure. Matric Group takes a proactive approach, helping you plan ahead with remanufacturing and repair services designed to extend the life of legacy equipment and reduce costly downtime.

With proven in-house capabilities and deep experience supporting long-life products, Matric Group can help you keep critical systems running reliably for years longer. The result is fewer surprises, better performance, and lower total cost of ownership, even decades after the original equipment was deployed.

Plastic waste may snag all of the headlines, but it's not the only type of waste overwhelming landfills and contaminating soil and water.

There’s a certain need for speed in manufacturing circuit boards -- the electronics industry demands it, and your end users demand it. But how quick...

Consolidating services is a great way to reduce costs, lead times, & confusion. Unfortunately, most electronics contract manufacturers (ECMs) don’t...