Coronavirus & How Electronic Medical Device Manufacturers Can Cope

As you know painfully well, the coronavirus is causing growing demand for medical ventilators and other "life-sustaining" devices. As hospital visits...

When it comes to making a custom electronic cable and harness assembly, the little details matter. A faulty wire or a bad connection could ruin an expensive piece of equipment and slow down manufacturing processes.

Here’s everything you need to know about cable assemblies and harnesses, from design to … well, assembly.

Ever removed the electrical panel in your car and seen all the fuses and outlets? Well, to get that neat, organized box, there’s a whole string of wires and cables running from different components to that one central hub. All those wires and cables are meant to transmit electrical power and certain signals, and the whole system together is known as the cable assembly.

Some people use the terms wire harness and cable assembly interchangeably, but in reality, they are two different assemblies.

Wire harnesses are meant for interior work, like within a personal computer or small electronics. These wires are usually individually sealed, then wrapped in another casing.

Because of their applications in small electronics or internal systems, wire harnesses are not as durable as cable assembly.

Similarly, cable assemblies are bundles of wires or cables in one casing. The difference is that a cable assembly uses heavier casings because the assembly is used in harsher environments. The casing usually consists of heavy-duty thermoplastic rubber or vinyl because it needs to hold up against

But what goes into making a cable and harness assembly?

The first, and most important step, of any electrical manufacturing process is pre-planned design. The same goes for developing a cable and harness assembly.

Depending on the application, the engineers will have to take extensive measurements to know how much wire is needed between each connection. They also have to account for a little bit of “give” for each connection -- you don’t want to struggle plugging in your connectors and break your painstaking wire work.

Every assembly is different, so for each new project there comes a new blueprint, but also new, exciting challenges!

Prototyping is a common practice in the electronics manufacturing industry.

Creating a test version of the final product is crucial in working out any kinks that weren’t ironed out in the design phase. Plus, prototyping gives engineers a chance to get their hands on the real thing, which helps them to come up with more efficient layouts or refine their blueprints.

Once the cable and harness design has been set in stone, it’s time to start putting the assemblies together.

There are a few key aspects of the manufacturing process that, unlike other electronics manufacturing, still rely on manual assembly. Some automation has been developed for cable and harness systems, but much of the work needs to be done by hand.

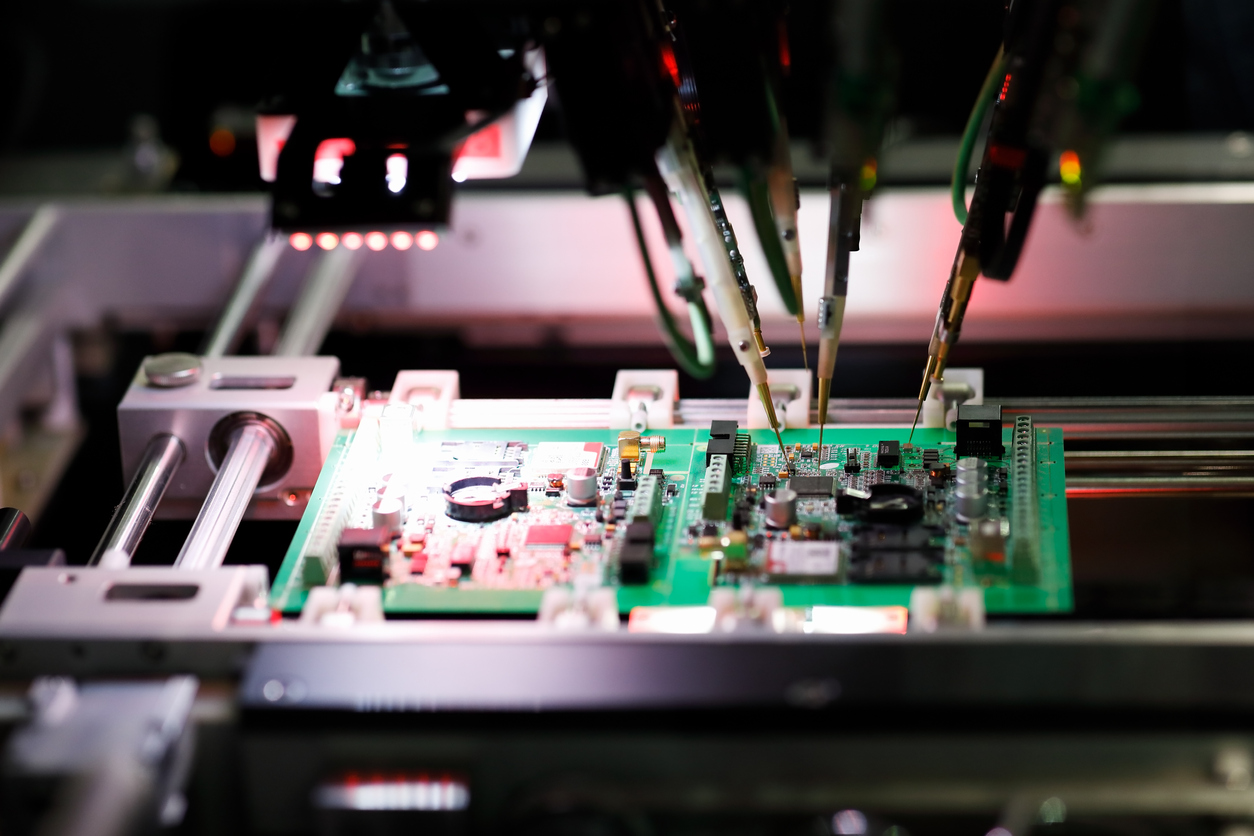

Time to slice some wire. This phase is largely automated, using wire-cutting machines to produce the correct lengths of wire in bulk.

Once the wire is cut, the casing is stripped back to reveal the core. Then, the exposed cores are fed into the necessary connectors. Some automation is available for this step, including crimping and soldering the wire into their proper connections.

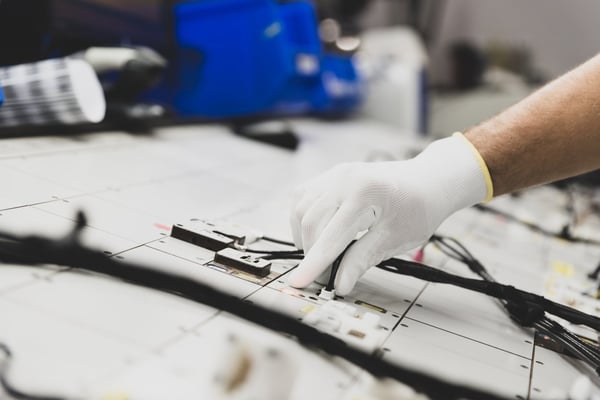

The prepared wires and their connectors are then gathered up and crafted into the harness itself. This step is where most of the manual labor comes in, because each wire needs fed through the harness, taped off, and measured to make sure the distances match the design specifications.

Manufacturing cable and harness assemblies can be rather time-consuming and expensive if you don’t have the right tools. Some electronics service providers are equipped with both the design and construction capabilities to see a project through from start to finish.

Tools needed for making a quality cable and harness assembly include:

When seeking an electronics manufacturing service provider, make sure they have the expertise and equipment to excel at cable and harness assemblies. Are they capable of:

Now you know the processes behind manufacturing custom cable and harness assemblies, and what to look for in a cable harness manufacturer. Before you decide on a partner, know your options!

Check out our manufacturing capabilities guide to learn more about what an electronic manufacturing services provider can do for you!

(Editor’s Note: This blog was originally published in June 2020 and was updated in July 2022.)

As you know painfully well, the coronavirus is causing growing demand for medical ventilators and other "life-sustaining" devices. As hospital visits...

OEM circuit boards are fundamental components in a wide range of consumer and commercial applications, from automobiles to household appliances and...

For many companies, the focus on printed circuit board (PCB) production is on-time-delivery and quality. However, just as important to a product’s...