Why Partner with an Electronics Contract Manufacturing Company?

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

Choosing the right electronic manufacturing services (EMS) supplier can play a big part in the success of your company. Pick the right partner and you can rely support that helps you achieve optimal results from your new product introduction. Pick the wrong EMS supplier and you are in for:

Choosing the right electronic manufacturing services (EMS) supplier can play a big part in the success of your company. Pick the right partner and you can rely support that helps you achieve optimal results from your new product introduction. Pick the wrong EMS supplier and you are in for:

Frustration

Hassles

Possible loss of capital

Negative impact on your business’s reputation

Fortunately, you can do a lot to ensure that your electronics contract manufacturer is the right fit. By conducting a careful search for suppliers for suppliers and asking the right questions, you’ll be able to verify the capabilities of potential suppliers and their suitability for your specific project needs.

Here are six questions you should ask before signing on the dotted line:

As the digital age evolves, the risks to your intellectual property are more significant than ever. It only takes one slip-up or act of carelessness to shoot a hole in your new product rollout that’s impossible to recover from.

If a company in China gets a hold of your design plans, they can turn around and build it for 10 cents an hour without paying for engineering and development fees. Then they can sell the product at a price with which you simply can’t compete. That’s why employees of companies like Apple can’t even talk to their dog about what they’re working on.

When you give the electronics contract manufacturer (ECM) the details to build an assembly, you are handing over extremely sensitive information. It’s critical that the ECM has systems in place to protect that information.

An non-disclosure agreement (often called NDA) should be in place for all your interactions with the EMS supplier. The ECM should be a paperless society, so no one can walk out the door with your files. All employees of a contract manufacturer should be required to sign the NDA so that they are on the hook to cover the IP.

If you’re making military or defense products, the EMS should also be certified with ITAR regulations -- important trade restrictions.

Basic aspects of a quality program include the ability to identify fake components and, of course, having the capability of placing them properly and precisely on the board. Does the contract manufacturer have testing and prototyping capabilities in-house? That’ll also determine the level of thoroughness you get.

Maybe most importantly, you need assurance that the EMS supplier is capable of ensuring and maintaining quality standards and regulations. Otherwise, there is no telling what you may end up with when your product arrives. A quality program should include certifications in the relevant industries, like:

ISO 9001 (aerospace)

ISO 13485 (medical devices)

Mining

And many others

Although it’s not a must-have, many businesses like to be within driving distance to do an audit of the EMS supplier’s facilities. If this is important to you, then make sure the electronic contract manufacturer is close enough to visit and that they welcome visits.

You’re totally within your boundaries in asking to see the machinery quality, facility cleanliness, etc.

Some board houses focus exclusively on simple, high-volume commodity orders and have no desire to do low-volume orders. Other EMS suppliers specialize in high-mix, low-volume orders that are more suitable for complex projects.

As a buyer, you need to be certain that the contract manufacturer is going to be able to meet your specific order requirements. Some simply can’t measure up -- or don’t want to.

Some well-rounded EMS companies can take on multiple -- or all -- steps of the manufacturing process to streamline your order.

They may be able to handle:

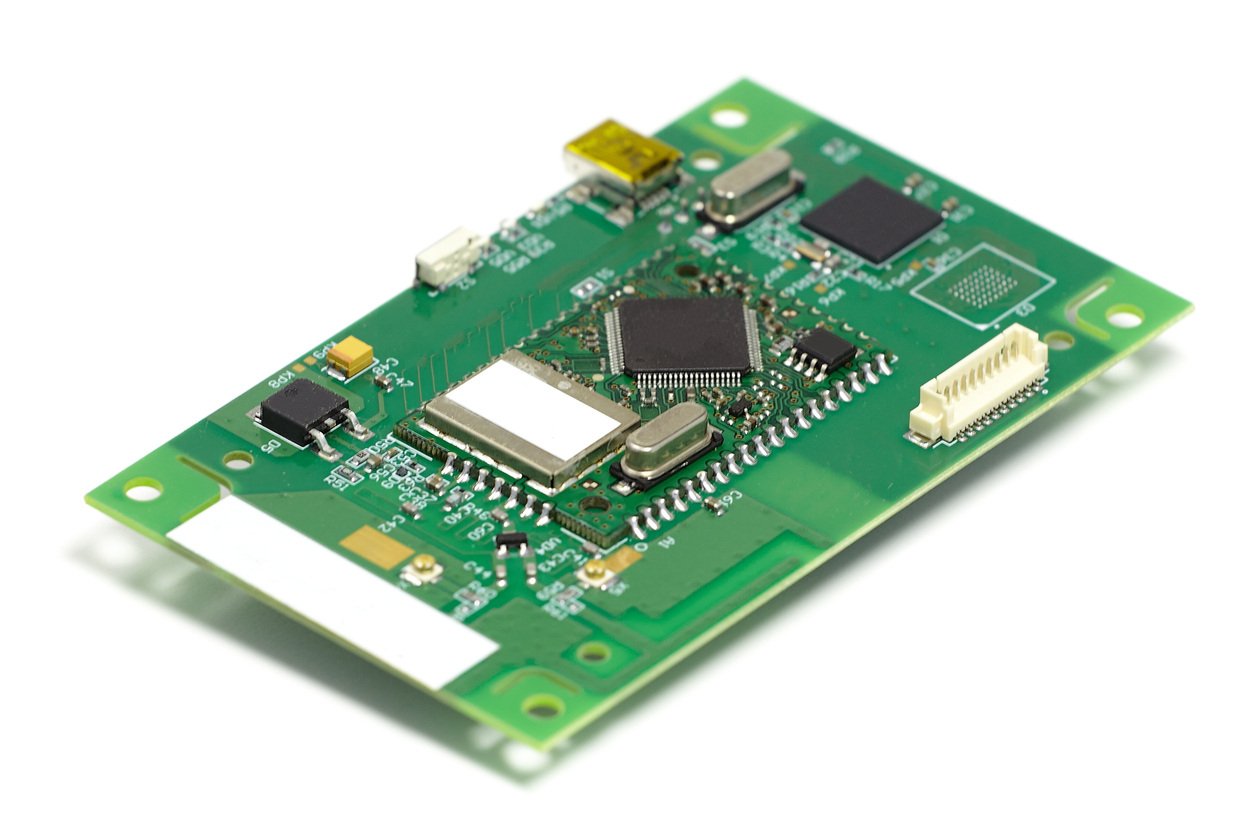

PCB design

PCB prototyping

PCB assembly

PCB testing & inspection

Wiring harnesses

Boxing

By giving you a complete final product, all you have to do is ship it to the end customer. Imagine the lead time, cost inefficiencies, and communication mix-ups you’ll cut down on.

Can the EMS troubleshoot your assemblies and make recommendations and help you succeed?

Some EMS suppliers are long-term, stable businesses with the deep pockets necessary to see a project through. Others … are practically working out of a garage.

Remember, the contract manufacturer typically has to go buy all your supplies, pay for labor, ship the product, and wait 30 days to get paid. That means the EMS supplier could be waiting as long as 6 months to get paid.

A financially sound ECM will be reliable and capable of giving you a clear picture of your costs from the start.

You’ll also want to verify that the EMS has been able (and willing) to invest in modern equipment -- not building your product on equipment from the Carter administration.

The whole point? Know what you’re getting into before working with an electronics contract manufacturer. They come in many flavors, based on:

Preferred volume

Quality/complexity capabilities

Certifications

Location and service radius

One-stop-shop capabilities

If you have any more questions about EMS companies, just ask one!

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

For those in the electronics manufacturing supply chain, RoHS compliance is a big deal. Hopefully you’ve treated it as such well in advance of the ...

“How will my idea go from conception to finished product at your company?” It’s a question we hear a lot, and a good one. It’s natural to want to...