Why Electronic Component Lead Times Are Rising -- & 3 Ways to Prepare

If your manufacturing projects involve electronics, you’re likely facing the challenge of extended electronic component lead times. Certain parts...

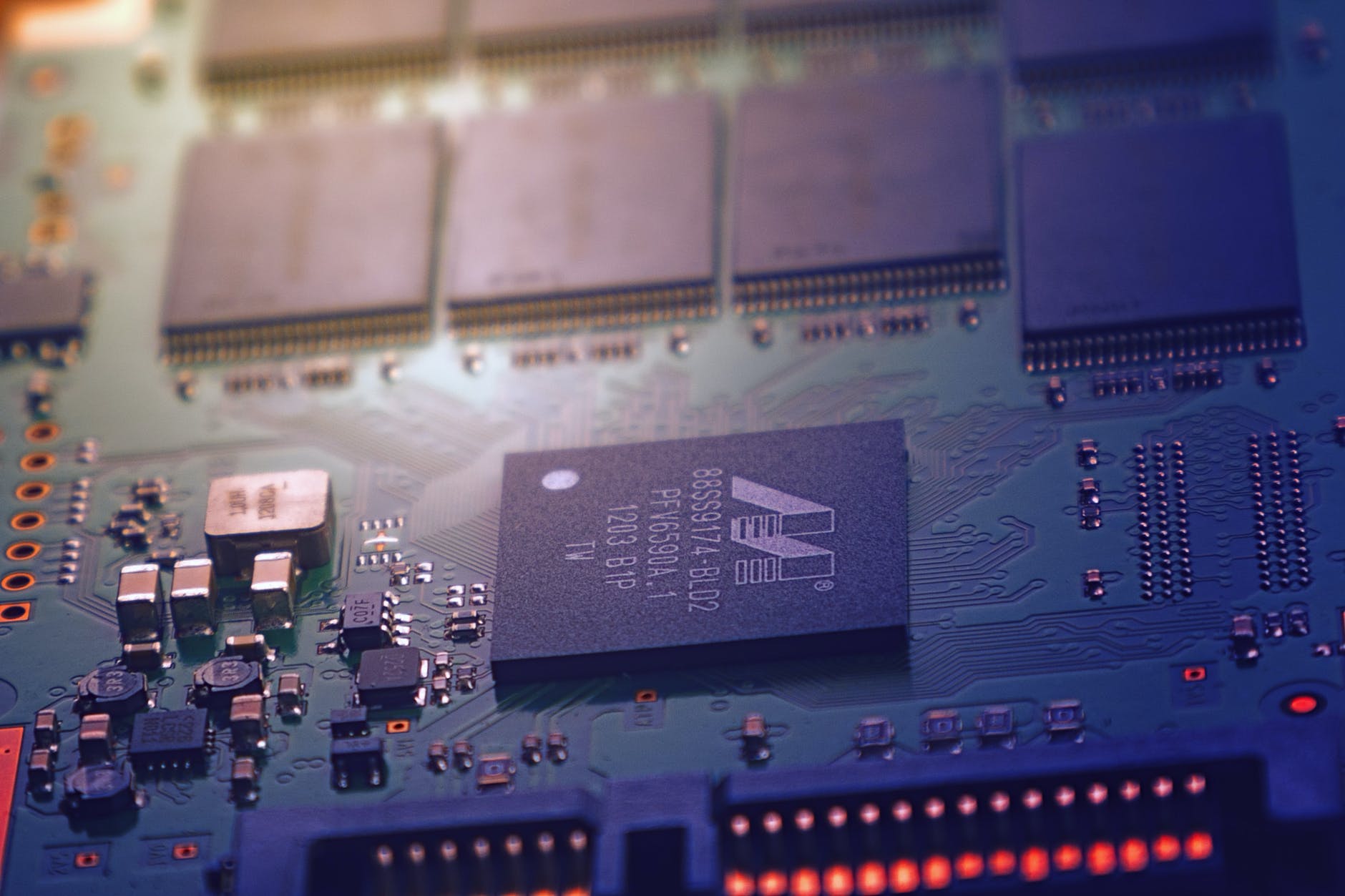

OEM circuit boards are fundamental components in a wide range of consumer and commercial applications, from automobiles to household appliances and IoT devices.

Through the years, PCB manufacturers have adapted to industry challenges by introducing a range of new technologies and practices. These advancements include PCB miniaturization, flexible printed circuits, and an increasing focus on green electronics.

PCB manufacturing embraces practices that conserve energy, lower carbon emissions, and use non-toxic, eco-friendly materials. We’ll cover the differences between lead and lead-free solder, compare their ease of use, and explore how your contract manufacturer can help your company stay compliant with RoHS guidelines which restrict hazardous substances in electrical and electronic equipment.

Lead solder (aka SNPB solder) is a metal alloy with lead (Pb on the periodic table of elements) and tin (Sn on the periodic table) as its base components. Many years ago, new U.S. plumbing systems banned lead pipes and any water supply pipes joined with lead solder. Later, the occupational risks of soldering with lead were also considered, and lead-based solder became a documented health hazard in the workplace. When inhaled, the dust and fumes generated by lead soldering practices are considered toxic.

For these reasons, lead solder continues to be phased out due to its negative environmental and health effects. But as a product manufacturer, you still want your contracted partners to deliver high-quality components with dependable, soldered connections and PCB circuitry.

Lead-free solder is a replacement for conventional 60/40 and 63/37 SnPb solder. In 2006 the Restriction of Hazardous Substances Directive (RoHS) was adopted by the European Union (EU), and the US followed suit by giving tax breaks to any company that reduced the use of lead-based solder. Today's lead-free solder will formulations that have a varied percentage of the following:

The end goal is to choose quality solder alloys that when combined with other trace metals will achieve excellent mechanical properties.

Considering soldering temperatures will depend on the alloy mix and quality, but typically 60/40 tin/lead solder will become liquid at 361°F. More often than not, the higher the tin content, the higher the melting point and product cost. Lead-tin solders are easier to work with; they flow well and reach working temperature quickly.

But, when it comes to safety, the risks of leaded solder are great and it should only be used when permitted by regulatory agencies. It must also be disposed of properly. Lead is harmful to the environment and is toxic to the body with the additional hazard of being so quickly absorbed into the bloodstream.

Lead-free solder paste will melt at higher temperatures of around about 422°F. Although the higher temperatures will necessitate a change in soldering practices, joints soldered with lead-free solder paste have proven to be reliable.

Because lead-free solder paste does not wet as well as leaded solder, expect solder joints to be different in appearance.

The reliability of any soldered joint or circuit run will hinge on reducing or eliminating soldering defects. To accomplish this, many factors must be considered, including:

All these factors, including the use of a quality solder paste, will play a role in manufacturing dependable PCBs. And when it comes to lead-free solders, it all boils down to choosing the right formulation and matching it with the right application. This is where your PCB fabricator is a valuable asset. Ideally, your partner will have extensive experience in RoHS material compliance.

When looking at solderability and the quality of lead-free solder vs. lead solder joints, expect a strong mechanical joint with lead-free solder. Lead solder forms a shiny and smooth solder joint for a higher appearance of quality. But, with PCBs and other internal electronics assembly, the consumer would rarely notice this difference.

The use of leaded versus lead-free solder paste will also have implications for the final product quality. But once again, when a PCB manufacturer implements tightly controlled soldering parameters, the effect is minimized. The design layout of the circuit board and the right component selection will overcome many quality control issues.

The choice of lead-free products for wave soldering or through-hole soldering is decided according to specific design parameters and product-use demands of the final assembled PCBs.

The higher temperatures associated with lead-free soldering mean proper board layout and component selection will be imperative to prevent metal decomposition or damage to sensitive electronic components. This is especially true during reflow when high temperatures are present for extended periods.

Frequently Asked Questions About Soldering & PCB ManufacturingBelow are frequently asked questions about lead and lead-free soldering and PCB manufacturing: What specific steps should a PCB manufacturer take to adapt to the higher temperatures required for lead-free soldering without compromising component integrity?To adapt to the higher temperatures required for lead-free soldering, PCB manufacturers should implement several key practices. First, they need to adjust their soldering equipment to accommodate the elevated temperatures, ensuring that soldering profiles are optimized for lead-free alloys. This might involve recalibrating reflow ovens and soldering stations to manage the increased thermal load. Additionally, manufacturers should use thermal management techniques to protect sensitive components from heat damage, such as improving heat dissipation through enhanced board design and using thermal buffers. Component selection should also be reconsidered to ensure that all parts can withstand the higher temperatures without degrading. Finally, preheating the PCB to reduce thermal shock and implementing rigorous quality control checks throughout the process can help maintain component integrity. How do the environmental and health regulations for lead-free soldering vary between different countries or regions, and what are the implications for international manufacturing?Environmental and health regulations for lead-free soldering can vary significantly between countries and regions. In the European Union, the Restriction of Hazardous Substances (RoHS) Directive mandates the use of lead-free solder in most electronic products, while the United States has adopted similar standards, although regulations can be less stringent and vary by state. Other regions, such as China and Japan, have also established their own regulations. For international manufacturing, these varying regulations mean that companies must ensure their products comply with local laws in each market where they are sold. This often involves coordinating with PCB manufacturers to adhere to specific guidelines and conducting thorough documentation and testing to prove compliance. Failure to meet these standards can result in legal penalties and market access restrictions. What are some practical challenges or limitations of using lead-free solder in high-frequency or high-precision electronic applications compared to leaded solder?Using lead-free solder in high-frequency or high-precision electronic applications presents several challenges. Lead-free solders typically have a higher melting point and different thermal and mechanical properties compared to leaded solders, which can affect signal integrity and component performance. For high-frequency applications, the increased solder joint resistance and reduced wettability of lead-free solders may impact signal transmission and cause interference. Additionally, the physical characteristics of lead-free solder can lead to differences in joint reliability, potentially resulting in increased risk of thermal fatigue or joint cracking. Manufacturers must carefully design PCBs and select components to mitigate these issues, often requiring more advanced materials and processes to achieve the same level of performance and reliability as with leaded solders. |

Quality consumer products demand good solder joints that don't introduce hidden resistance into the circuit or act as a heat intermediary that may promote thermal-mechanical fatigue. When you specify lead-free solder to be used in PCB manufacturing, there is a reduced chance of cold, dry joints that lack mechanical strength.

Your PCB manufacturer should help you handle all RoHS material compliance issues that affect your electronic PCBs. As the US markets are experiencing a gradual change to lead-free soldering practices, many companies are following the EU's RoHS lead with restrictions on lead use in electronics. This means your devices can be manufactured in America and sold in Europe.

A single modification in soldering materials and/or techniques can change the entire PCB/device assembly and manufacturing process. Your PCB contractor's goal is to ensure your PCBs and final products are manufactured efficiently and economically, without sacrificing time to market.

To learn more about other electronics manufacturing regulations that may impact your design, download our free e-book below:

(Editor’s Note: This blog was originally published in November 2020 and was updated in August 2024 to reflect current information.)

If your manufacturing projects involve electronics, you’re likely facing the challenge of extended electronic component lead times. Certain parts...

So, you’ve made the choice to design a custom PCB for your design. Instead of buying off the shelf electronics.. but what’s next?

At this point, we’re all familiar with light-emitting diode (LED) lights. From the bright, efficient bulbs replacing the old filament lamps, to the...