Why Partner with an Electronics Contract Manufacturing Company?

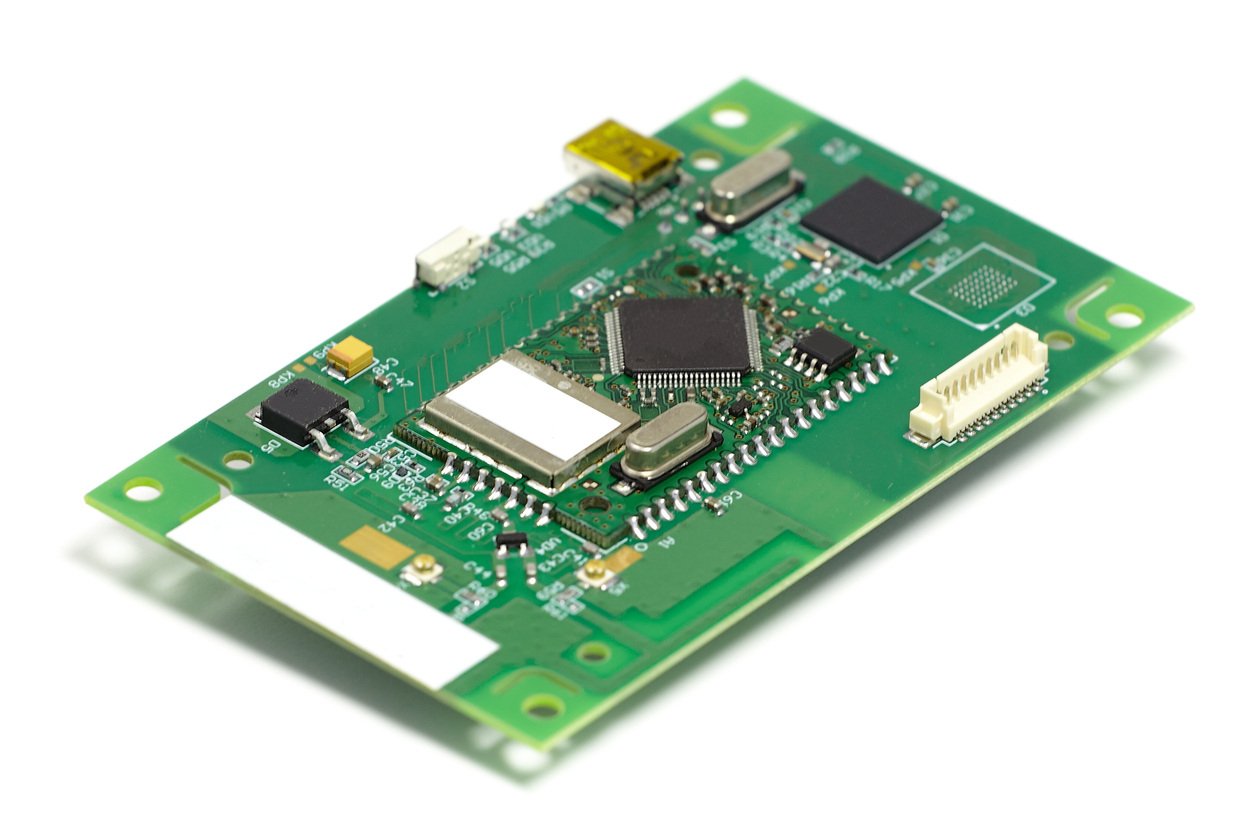

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

There’s a certain need for speed in manufacturing circuit boards -- the electronics industry demands it, and your end users demand it. But how quick is too quick?

There’s a certain need for speed in manufacturing circuit boards -- the electronics industry demands it, and your end users demand it. But how quick is too quick?

Many product makers on a tight schedule contract with quick-turn PCB houses rather than a full-service PCB contract manufacturer. While there are some situations where a PCB board house can make sense, in most cases you’ll be left unsatisfied.

There are four cases where it’s especially beneficial to take the long road to success with a full-service contractor:

It’s dangerous to do a rush job on contract manufacturing PCB assembly. The risks of working with a quick-turn house include:

If your assembly isn’t fully proven and you’re just getting to manufacturing it for the first time, hiccups and bugs are inevitable. Things may not work the way that you expect them to. Your design may not be manufacturable in its current form. It happens.

A simple board house may not give you the support you need to deal with these situations. Fortunately, many full-service ECMs (electronics contract manufacturers) insist on handling functional testing. A robust PCB design company will rarely just build to print.

When a full-service ECM gets your Gerber file, it will follow that to determine how to populate the PCBs -- and that’s only step one. However, quick turn board houses will often just populate and send it off.

In other words, they don’t even make sure it works. Their approach is one of, “If it doesn’t work the way you want it to work, that’s your fault.”

An all-in-one ECM will:

True ECMs will fully match the parameters you expect of the board so that when it leaves the factory, it’s doing what it should.

Board houses aren’t really there for a long-term relationship. They’re about getting contracts and fulfilling them as soon as possible – without really being concerned about problems with the product.

Sometimes, it just helps to have a second set of eyes, especially with a new product.

As the name implies, quick-turn houses want to turn around projects ASAP. To accomplish this, they often work closely with one or two component manufacturers -- like DigiKey or Mouser. Sometimes this is literally -- they’ll set up shop right next to a DigiKey or Mouser distributor.

You don’t have the option of using other component brands and types when you use these board houses. If you have a custom assembly, it may be a roadblock to working with such a company.

If your project is rife with obsolete components, most board houses won’t be willing to find alternatives.

A full-service ECM will instead look for alternatives through third-party obsolescence software. If switching in alternative components isn’t enough, the contractor can “respin” or redesign the board.

That way you’re not left to solve problems on your own. Instead of your product reaching end-of-life, you’re actually taking it into the next stage of its life.

Sometimes you can get away with a quick-turn service. Sometimes you just can’t help it. You can turn to a board house when you:

Quick-turn PCB manufacturers can get you places. But they need the path paved for them.

ECMs don’t follow a turn-and-burn strategy. They try to meet delivery times but also are deliberate about getting things right. You also get engineering help and customer interaction -- the feeling of comfort that comes from working with someone you have partnered with for years.

Don’t undervalue having a partner that truly understands your product. Over the years, an ECM may come to understand your product so well that they think of potential issues before you do -- and offer solutions before the problem becomes bigger.

You can certainly handle contract PCB assembly on a case-by-case basis with board houses. Just remember: Sometimes, in manufacturing, speed kills.

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

When talking with salespeople, design engineers, and other contacts within an electronic contract manufacturer, you may hear a lot of terms thrown...

1 min read

The decision on which electronics manufacturing supplier to choose can be a difficult one. The outcome of the quoting process often decides who...