2025 Tariffs on Electronics from China: Design and Source Smarter

NOTE: This article was updated on July 3, 2025 to reflect recent information regarding tariffs.

1 min read

Matric Group

:

Nov 28, 2018

Matric Group

:

Nov 28, 2018

Maintaining an accurate inventory can result in an elevated manufacturing process, increasing efficiency in production, ensuring on-time delivery, and allowing for timely action in the event of bottlenecks.

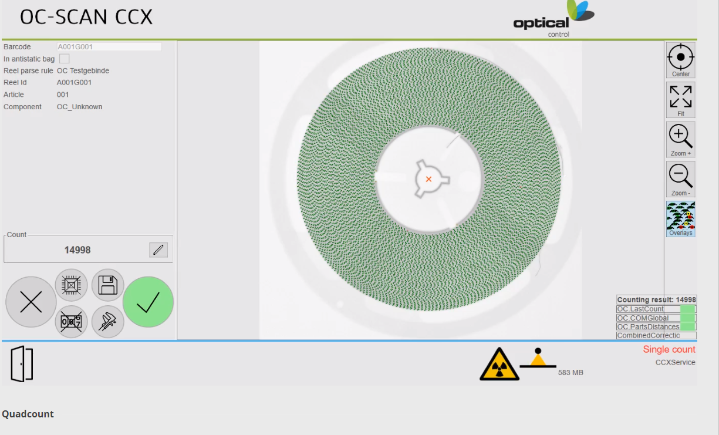

In electronics manufacturing, accurate component inventory management is critical. At Matric, we recently invested in an X-ray automatic component counter. This addition to our production floor further adds to our ability to maintain an accurate and efficient inventory process.

Since its arrival, we can’t say enough good things about this machine, an Optical Control OC-Scan CCX.3. Not only for the headaches it saves our associates during component inventory, but also for the positives it passes along to our customers.

Let’s take a look at some of those positives that make life easier for customers.

An automated inventory system provides, above all else, increased productivity. With exact component counts, an EMS provider can reduce downtime and the number of setups during runs. Once an order has finished production, an immediate post-order calculation of consumed material happens.

Basically, you should always have an accurate depiction of your inventory levels.

Component stock shortages delay orders all the time. With automatic component counts, you can more accurately predict needs for future orders, reducing the amount of special procurements and budget-hijacking additional purchases.

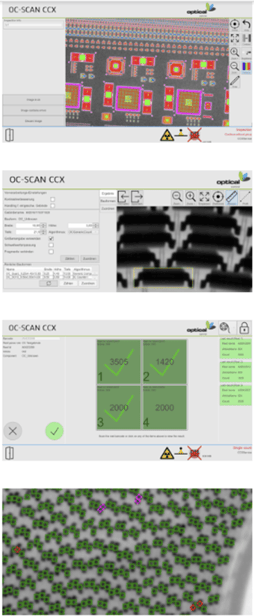

Reeled components in high-volume packaging can be difficult to count. Optical Control’s software is designed to make this process easier, giving you superior counting results.

A highly automated process, an x-ray counter provides a faster, more precise measurement than humans alone can provide. With “Quad Count,” counting is possible for up to four 7” reels at a time, which takes less than 20 seconds.

This maintenance-free system can run 24/7 and securely stores information in an on-site database, allowing for easy access.

Knowing exactly how much inventory you have can truly steady your ship. By reviewing the database, you can foresee bottlenecks before they arise. You’ll maintain a proper production timeline through precise material management and observance of confirmed delivery dates.

.jpg)

NOTE: This article was updated on July 3, 2025 to reflect recent information regarding tariffs.

Two things are fairly certain about the current electronic component shortage: It’ll end, and it’ll someday return.

If there's anything certain in the U.S.-China tariffs staredown, it's uncertainty.