Guide to Making an Electronics Box Build Assembly

If you’ve put in the hard work of designing an electronic product, chances are you have high expectations for its success with your target market....

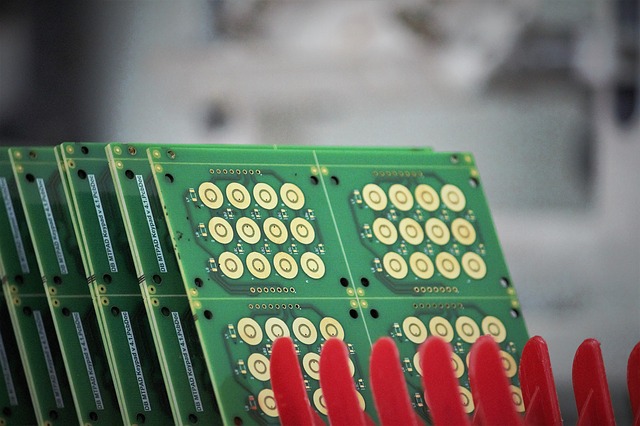

As with most things you can purchase, there’s a strenuous relationship between cost and quality with PCB assemblies. However, there is a happy medium to be found between the two, and these tips can help reduce PCB assembly costs without sacrificing quality.

Reducing cost is possible from the very first step in the process. Your bare PCB design can be optimized to prevent errors and reduce cost. You can subject your PCB’s to a design-for-manufacturing (DFM) test, offered free of charge by some manufacturers, to discover possible areas of concern.

If you are designing your board in-house, free software like Eagle is available to produce your schematic. You can read about some of its benefits and comparisons to similar software here.

Component sourcing requires a lot of time and dedication. Issues like obsolete parts cause headaches and complicate matters further. For that reason, it makes sense for smaller companies to rely on manufacturers to handle these duties.

Most PCB assemblers offer some sort of strategic sourcing service and can usually procure components at wholesale prices.

The bill of materials is simply a list of parts and components used on a PCB. It contains critical information like part number, manufacturer’s name, quantity, and component replacements.

Be sure to accurately include all necessary information when submitting your bill to reduce back-and-forth time.

Inspection services usually add to cost, but the benefits are far more important. Many manufacturers offer in-house inspection, saving you from outsourcing to another third party company. The use of in-line inspection equipment or burn-in testing helps assure the quality of your product before it ever leaves the manufacturing floor.

Research which type of inspection equipment is best for your assembly. Services burn-in test, automated and x-ray inspection are all options that depend on your board’s component type, layer count and your own preference.

(Editor's note: This blog was originally published in May 2018 and was updated in October 2023 to reflect the most up-to-date information.)

If you’ve put in the hard work of designing an electronic product, chances are you have high expectations for its success with your target market....

Box build assembly. Systems integration. Top level assembly.

More manufacturers these days are realizing the benefits of using external PCB assembly services versus a DIY approach. Allowing an electronics...