3 min read

Knowing the Importance of the IPC 6011 Standard in PCB Manufacturing

In the demanding field of printed circuit board (PCB) fabrication and manufacturing, closely adhering to industry standards is crucial for an OEM's...

3 min read

In the demanding field of printed circuit board (PCB) fabrication and manufacturing, closely adhering to industry standards is crucial for an OEM's...

7 min read

In the digital age, where transactions are often completed with a mere tap or click, the seamless operation of financial systems has become a...

3 min read

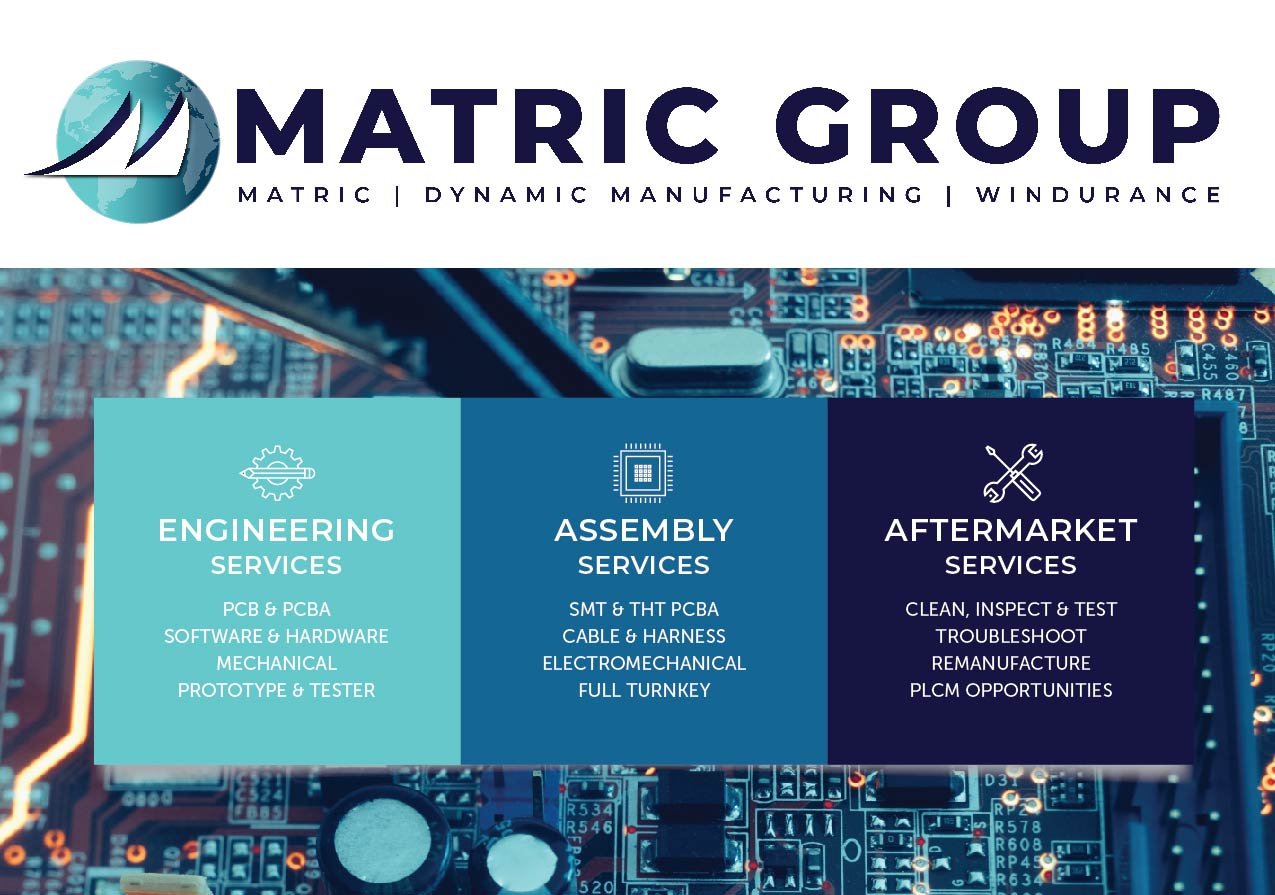

If you’re looking for an electronics contract manufacturer, what are the most important factors you consider? Is it the price or quality of the...

2 min read

(Photo courtesy U.S. Air Force) Electromechanical PCB box build assembly services are one of the most important offerings of electronics contract...

3 min read

Medical device product life cycle management is a challenge at the best of times. It becomes even harder when supply chains are disrupted (such as...

2 min read

Global supply chain shortages mixed with bottlenecks in the shipping industry and labor shortages have triggered serious problems in nearly every...

2 min read

A first article inspection for electronics products is a verification process that documents and certifies the accuracy of each and every facet of...

2 min read

PCBs have been getting smaller for the past few decades, and few industries have taken more advantage of that than the medical industry. While that’s...

3 min read

Medical device companies looking for a PCB design and assembly partner have many important factors to consider, all with the end user’s well-being at...

2 min read

As with most things you can purchase, there’s a strenuous relationship between cost and quality with PCB assemblies. However, there is a happy medium...

3 min read

Deciding on the best testing method for your printed circuit board can be a daunting task. There are plenty of factors to take into consideration,...

1 min read

Fall in the Northeast means a lot of fun activities in your personal life and year-end planning and reporting in business. It also can mean a lot of...

5 min read

As young people enter the workforce, it is important to develop and possess certain qualities in order to be successful. Employers expect individuals...

3 min read

Understanding your marketing is key to a successful product run. That applies not only to your customers, but their home country as well.

2 min read

In the constantly evolving world of technology, safety remains a top concern among engineers during development. Whether it’s a sensor in your car,...

3 min read

The most painful part of developing with electronics is knowing your success is fleeting. Eventually, all parts must die, or at least fade away into...

3 min read

While there are many common printed circuit board defects, one of the most notorious is burnt components. It's also, unfortunately, one of the most...

3 min read

The adage “If it’s not broken, don’t fix it” holds no ground in the realm of public transportation, mining equipment, and numerous other high-stakes...

4 min read

With the rise of IoT and technology in general, electronics are featured in many environments, exposing delicate electronic connections to potential...

2 min read

The Design-2-Part show for the Greater New York area will be held April 26-27 in Secaucus, NJ.

6 min read

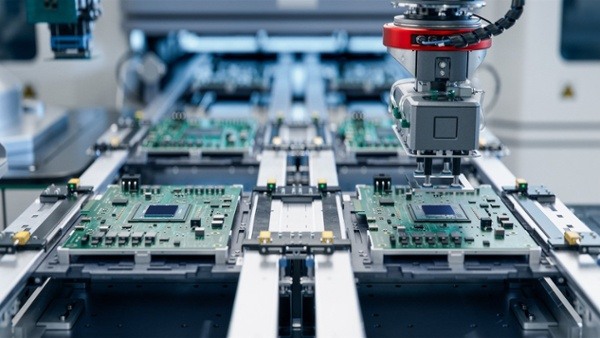

The world of PCB assembly capabilities is changing rapidly, and forecasters expect PCB manufacturing capabilities to expand for the next 10 years....

3 min read

When an OEM is sourcing out work -- let alone aerospace electronics manufacturing -- it’s likely to come across companies that boast about all sorts...

3 min read

In 2006, the European Union rolled out a directive restricting the use of certain hazardous chemicals. This directive, Restriction of Hazardous...

2 min read

As today’s electronics designs become smaller and more complex, more engineers are relying on surface mount technology. After the 1980s, this...

3 min read

Among the serial data interfaces -- SPI, Flex I2C, and many more -- available for electronic equipment, two stand out for their longevity. In spite...