6 min read

PCB Testing Methods: How to Test a PCB & Ensure Circuit Board Reliability

When you order printed circuit boards, you already understand the costly consequences of failure. The last thing you need is for your PCBs to...

6 min read

When you order printed circuit boards, you already understand the costly consequences of failure. The last thing you need is for your PCBs to...

3 min read

There’s no perfect playbook to establishing and maintaining major transportation projects like subways, bus systems, and other transit developments.

2 min read

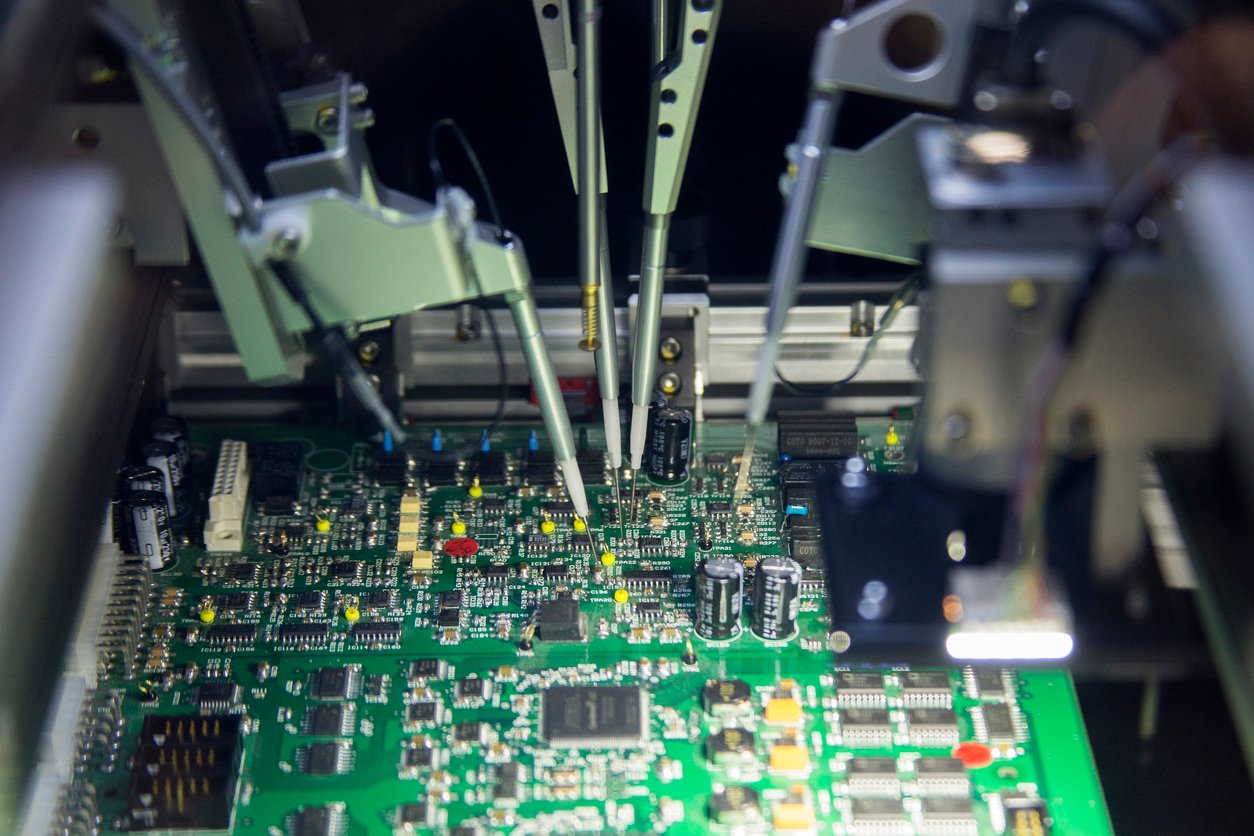

Testing and inspection are vital parts of electronics contract manufacturing, for obvious reasons. Before that shipment of PCBs arrives on your...

2 min read

Solder is what makes the electrical connections work on your printed circuit board (PCB). Solderability, then, measures how well metal is wetted by...

3 min read

PCB contamination testing is not for every project, but it’s a lifesaver for some.

4 min read

In electronics manufacturing, printed circuit boards are categorized based on the IPC Class Definitions: Class 1, Class 2, and Class 3.

2 min read

Let’s face it, soldering can be a challenging task. Even with years of training and the most advanced machinery, PCB soldering defects are sometimes...

4 min read

Electronic component shortages didn’t fade away in 2024 – and they’re still making life complicated in 2025. Lead times have improved since the worst...

3 min read

Major regulation changes have come to electronics in recent years, and it’s important for everyone to take note, including U.S. manufacturers who...

.jpg?width=788&height=443&name=iStock-1373244125%20(2).jpg)

6 min read

NOTE: This article was updated on July 3, 2025 to reflect recent information regarding tariffs.

4 min read

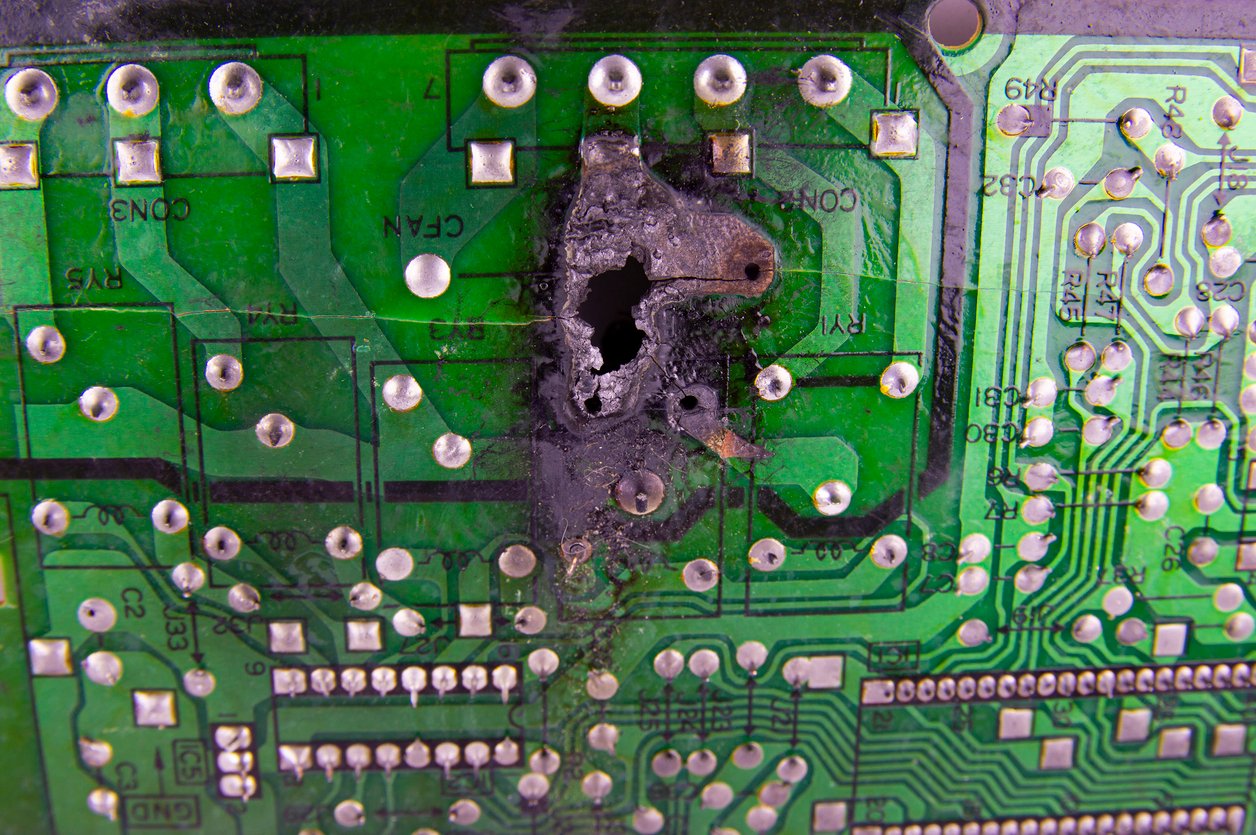

Printed circuit boards (PCBs) are the foundation of almost every electronic product. When one fails, the results can include product recalls, costly...

4 min read

PCB design can be challenging. The complexity of your project and the potential consequences of PCB failure may require thorough, high-level testing...

6 min read

Bringing a new electronic product to market is no small feat. From intricate circuit board designs to complex cable assemblies, every detail must...

4 min read

When reliable performance matters – whether in medical devices or handheld mining tools – every component in your design needs to contribute to...

5 min read

The tech world moves at lightning speed. Bringing an electronic product to market requires more than just a great idea — it demands precision,...

3 min read

Working with small circuit board areas can increase the risk of various PCB defects, tombstoning in particular. While the grim nature of “tombstone”...

5 min read

When building the next generation of electronic products, the last thing you want is to be sidelined by production issues, faulty boards, or...

5 min read

The electronics manufacturing supply chain is a major risk for many OEMs. Challenges in this area include environmental and global regulations, which...

3 min read

Join Matric atThe Battery Show 2024, a premier event for the battery and electric vehicle technology industries.

2 min read

Matric will attend MINExpo 2024, the world’s largest mining trade show, from September 24-26 at the Las Vegas Convention Center in Las Vegas, NV.

4 min read

When it comes to military electronics, reliability is non-negotiable. Whether it’s a navigation system guiding a ship through dangerous waters or a...

5 min read

Driven largely by technological advancements and the increasing demand for efficient trading solutions, the financial technology landscape is...

5 min read

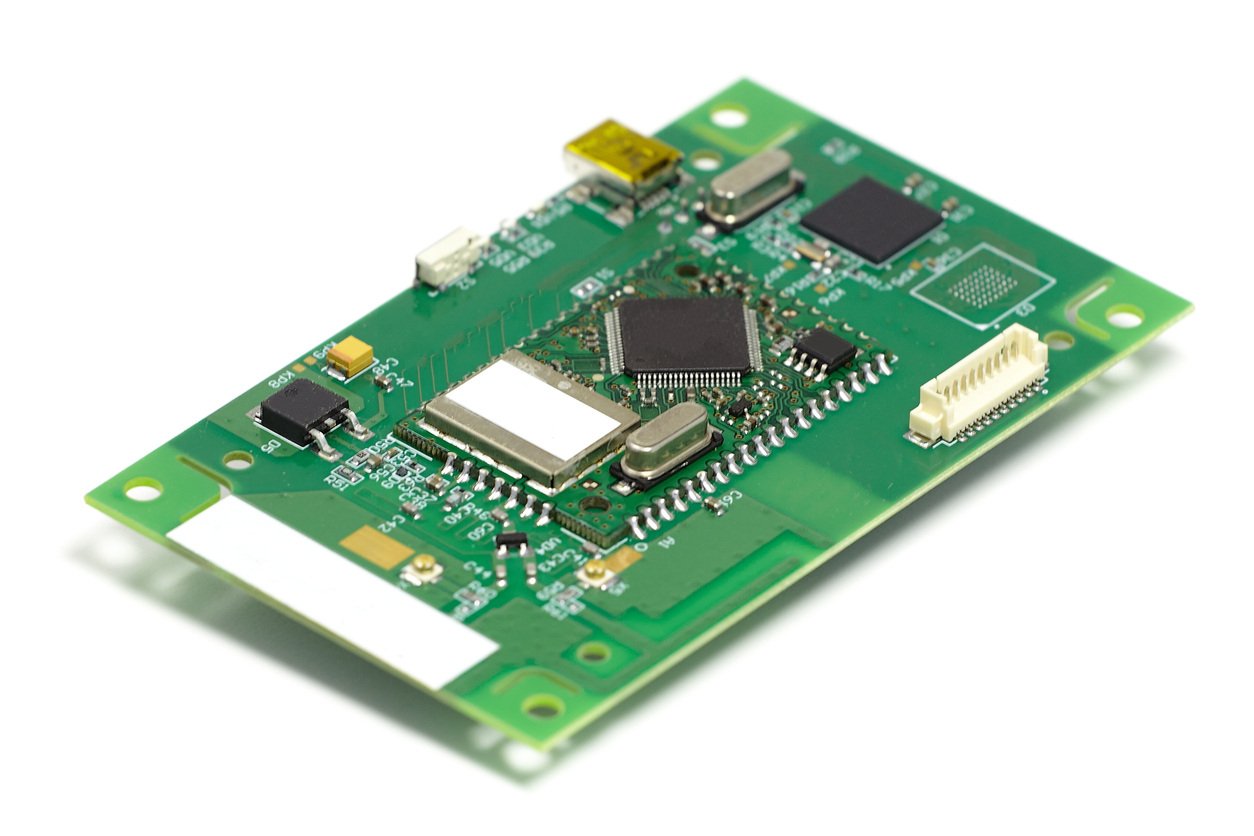

OEM circuit boards are fundamental components in a wide range of consumer and commercial applications, from automobiles to household appliances and...

4 min read

Confused about REACH vs. RoHS compliance? You’re not alone. These two sets of electronics manufacturing guidelines were born from the European...