3 min read

Matric to Showcase Expertise at The Battery Show 2024

Join Matric atThe Battery Show 2024, a premier event for the battery and electric vehicle technology industries.

Read More

3 min read

Join Matric atThe Battery Show 2024, a premier event for the battery and electric vehicle technology industries.

Read More

2 min read

Matric will attend MINExpo 2024, the world’s largest mining trade show, from September 24-26 at the Las Vegas Convention Center in Las Vegas, NV.

4 min read

When it comes to military electronics, reliability is non-negotiable. Whether it’s a navigation system guiding a ship through dangerous waters or a...

5 min read

Driven largely by technological advancements and the increasing demand for efficient trading solutions, the financial technology landscape is...

6 min read

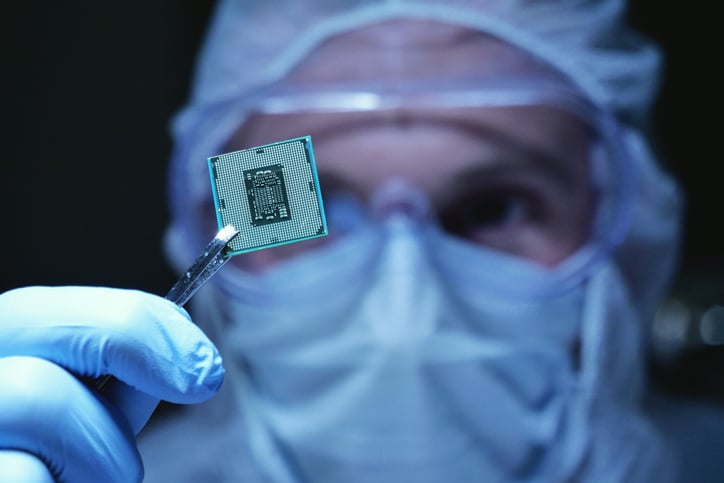

Want to get smaller, lighter, or more powerful? (Who doesn’t?) In electronics, customers are demanding all three – at the same time. It might seem...

5 min read

OEM circuit boards are fundamental components in a wide range of consumer and commercial applications, from automobiles to household appliances and...

4 min read

Confused about REACH vs. RoHS compliance? You’re not alone. These two sets of electronics manufacturing guidelines were born from the European...

3 min read

In the demanding field of printed circuit board (PCB) fabrication and manufacturing, closely adhering to industry standards is crucial for an OEM's...

3 min read

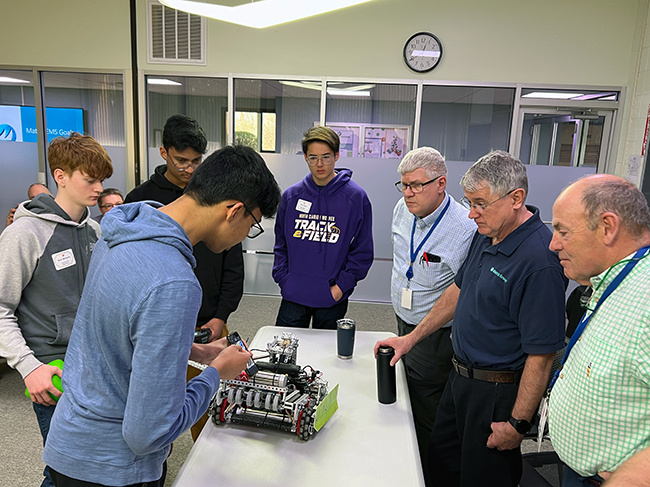

Clarion Jr. Sr. High School Robotics team demonstrates their robot entry for an upcoming competition. A business is not an island. Just as you create...

5 min read

Printed circuit boards (PCBs) have been instrumental in the rapid advancement of technology since their introduction in the 1940s. PCBs...

4 min read

PCBs are crucial to modern financial systems and play a critical role in the infrastructure that supports the global financial ecosystem. These...

7 min read

In the digital age, where transactions are often completed with a mere tap or click, the seamless operation of financial systems has become a...

1 min read

Are you ready to develop new partnerships? Not having luck finding manufacturers in certain industries? A visit to one of this year’s D2P shows can...

3 min read

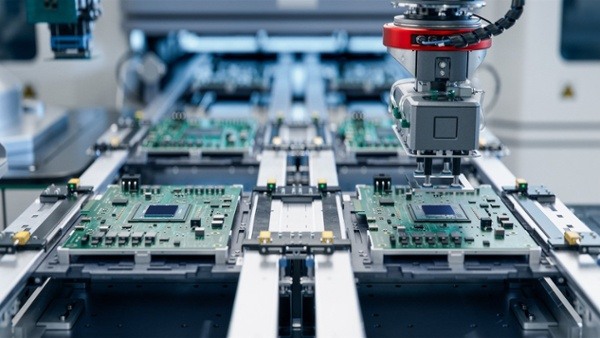

If you’re looking for an electronics contract manufacturer, what are the most important factors you consider? Is it the price or quality of the...

4 min read

Data centers are crucial for the financial industry due to their pivotal role in ensuring speed, reliability, and security, which are fundamental for...

2 min read

(Photo courtesy U.S. Air Force) Electromechanical PCB box build assembly services are one of the most important offerings of electronics contract...

3 min read

Medical device product life cycle management is a challenge at the best of times. It becomes even harder when supply chains are disrupted (such as...

4 min read

PCBs for kiosks represent a specialized area within electronics manufacturing, requiring a focus on durability, security, and diverse component...

2 min read

Global supply chain shortages mixed with bottlenecks in the shipping industry and labor shortages have triggered serious problems in nearly every...

2 min read

A first article inspection for electronics products is a verification process that documents and certifies the accuracy of each and every facet of...

2 min read

PCBs have been getting smaller for the past few decades, and few industries have taken more advantage of that than the medical industry. While that’s...

3 min read

Medical device companies looking for a PCB design and assembly partner have many important factors to consider, all with the end user’s well-being at...

3 min read

As the world of robotics advances, PCB manufacturing techniques have become faster and more efficient. With surface mount technology, flexible PCBs,...

2 min read

As with most things you can purchase, there’s a strenuous relationship between cost and quality with PCB assemblies. However, there is a happy medium...

4 min read

In today’s world of advanced technology, it could be two days before someone detects a cyberattack on your system. At that point, data and...