6 min read

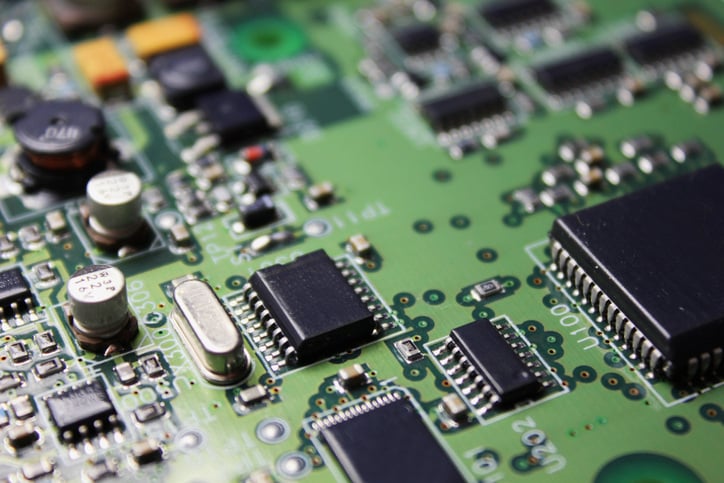

PCB Testing Methods: How to Test a PCB & Ensure Circuit Board Reliability

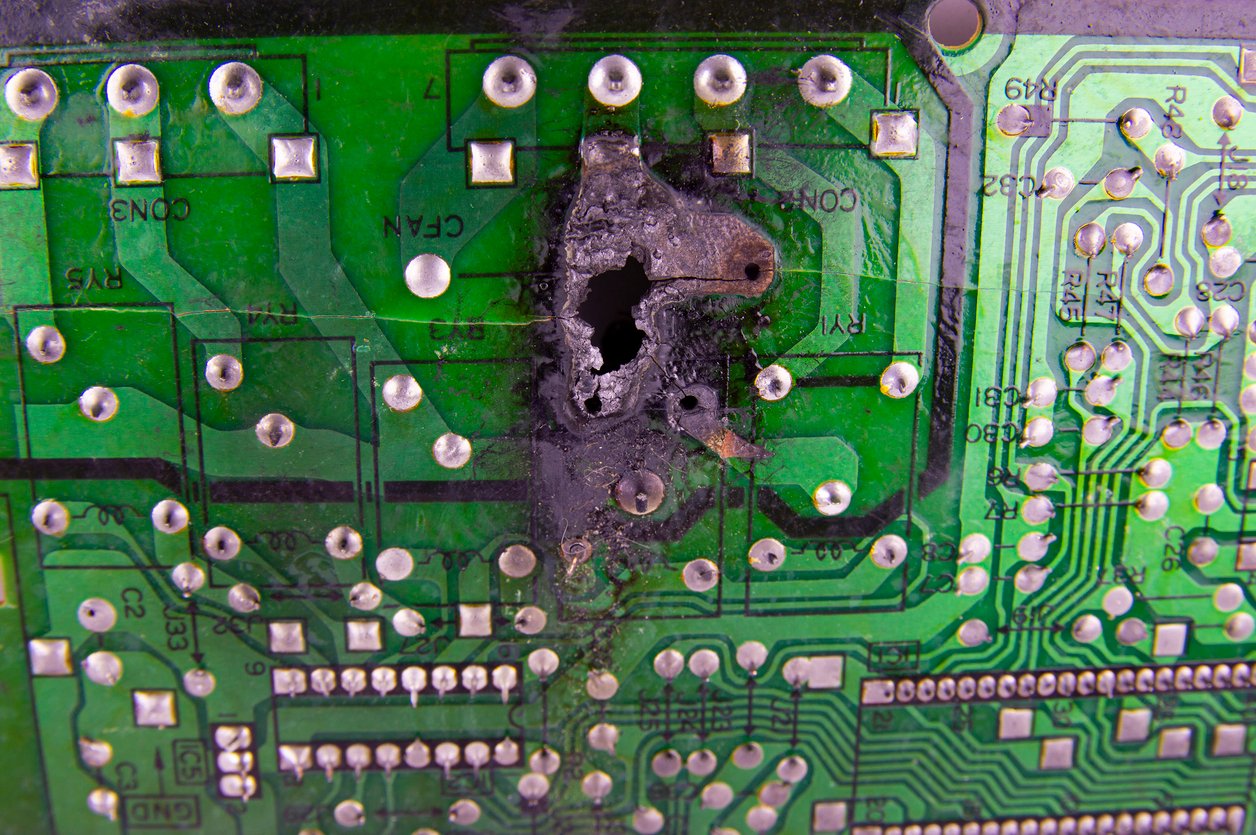

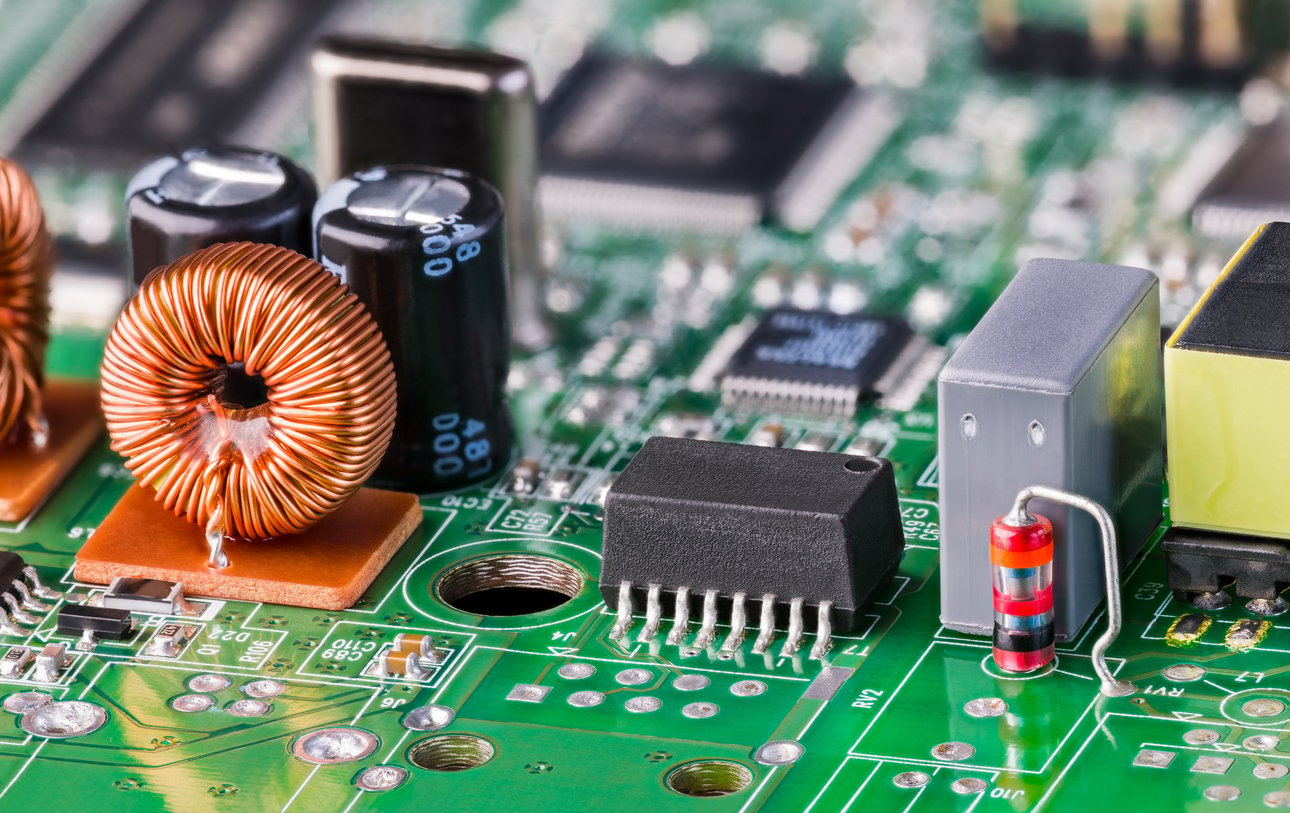

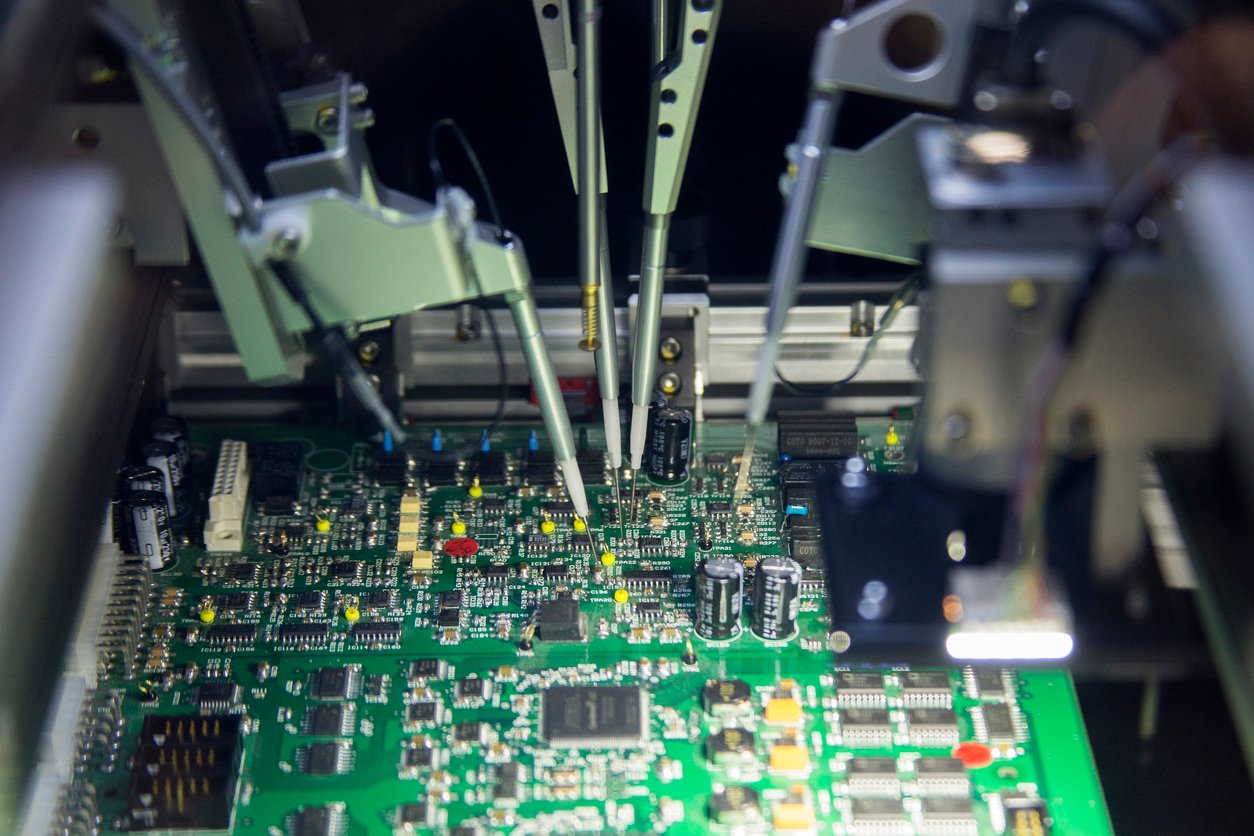

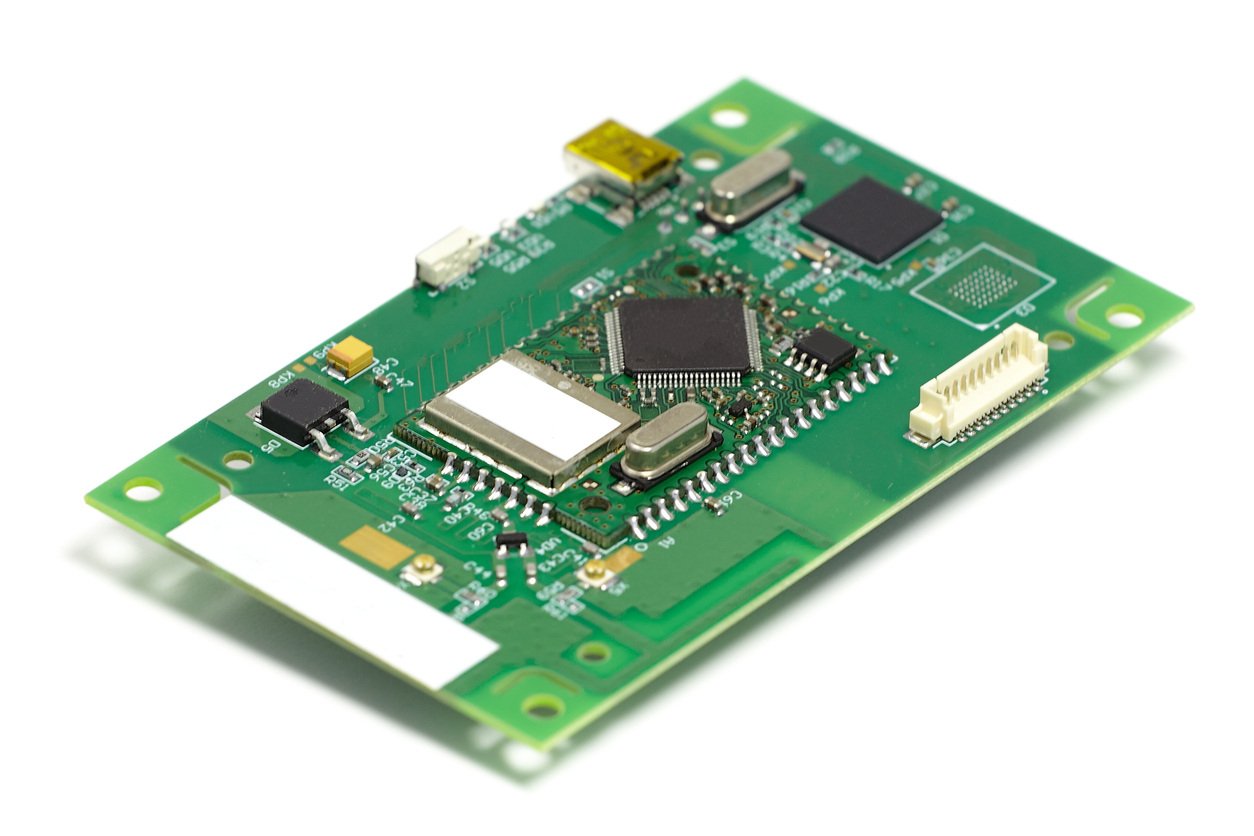

When you order printed circuit boards, you already understand the costly consequences of failure. The last thing you need is for your PCBs to suddenly fail or have a shortened lifespan because of a design or QA issue. PCB assembly testing methods...

Read More

.jpg?width=788&height=443&name=iStock-1373244125%20(2).jpg)