RoHS-Compliant Countries That Aren’t Actually RoHS-Compliant

It seems simple enough. If you’re a manufacturer who uses electronic components to build your products for American or international markets, you...

For electronics OEMs and contract manufacturers, a proper RoHS declaration of conformity isn't just paperwork — it's your legal shield and ticket to the market.

In 2026, RoHS conformity will matter more than ever, not only for ensuring global market access, but also for protecting legal liability against regulatory penalties and for meeting increasing customer requirements. With several RoHS exemptions set to expire, proactive planning is crucial.

In this guide, we’ll clarify RoHS documentation requirements and declarations for manufacturers, helping you better prepare for 2026. Whether you're dealing with exemption expirations, supply chain complexities, or documentation audits, you'll find practical guidance to streamline your compliance process.

Navigating RoHS compliance documentation can feel overwhelming, especially with regulatory changes on the horizon.

A declaration of conformity serves as your legal statement that a finished product meets all applicable RoHS substance restrictions. This document goes beyond a simple compliance claim — it represents your organization's formal commitment to regulatory adherence.

The RoHS declaration covers your complete product, including all components, subassemblies, and materials. Unlike component-level compliance statements from suppliers, your RoHS letter takes responsibility for the entire finished good as it enters the market.

Your RoHS declaration template must include specific elements:

Include the following for the entity placing the product on the market:

Provide clear identifiers for the product(s) covered by the declaration, including:

Reference the applicable legislation to ensure regulatory accuracy:

List the technical standards applied during compliance assessment, such as:

Identify the person with legal authority to bind the organization:

Your RoHS declaration of conformity requires strong technical backup. This supporting documentation typically includes:

Maintain clear traceability between your RoHS declaration and supporting evidence. Auditors and customers expect to see logical connections between your compliance claims and underlying technical proof.

Missing product identifiers represent the most frequent error in RoHS declarations.

|

For example: Vague product descriptions like "electronic device" won't satisfy regulatory scrutiny — specify exact model numbers and variants. |

Outdated directive references create compliance gaps. Ensure your RoHS compliance letter cites the current regulatory versions, not superseded directives from years past.

Unnamed responsible persons weaken your declaration's legal standing. Generic signatures or missing authorization details can invalidate your entire compliance statement during audits.

Vague exemption claims without proper justification expose you to regulatory challenges. If claiming exemptions, provide a specific technical rationale and regulatory references.

To avoid these common pitfalls and ensure a sturdy RoHS declaration, be sure to understand and define responsibilities across your entire supply chain.

Each entity — from OEMs to component suppliers — plays a key role in maintaining compliance:

As the OEM, you hold ultimate legal accountability for your RoHS declaration, even when outsourcing manufacturing or purchasing components from suppliers. This responsibility cannot be transferred to contract manufacturers or component suppliers through contractual arrangements.

Your RoHS declaration of conformity represents your organization's commitment to customers and regulators. While you rely on supplier data, the final compliance determination and declaration signature remain your responsibility.

Component suppliers must provide part-level compliance statements supporting your RoHS declaration. These statements should include:

Suppliers should maintain updated documentation reflecting current product formulations and notify customers immediately of any compliance-impacting changes. Regular supplier audits help verify the accuracy of compliance claims supporting your RoHS letter of compliance.

Many manufacturers adopt a 10-year record-retention period (linking components, BOM, part numbers, and your RoHS declaration) to ensure traceability during audits and investigations. While this is widely accepted, you should verify applicable national transposition or guidance in your market.

Document version control ensures your RoHS declaration template reflects current product configurations. When components change, corresponding compliance documentation must be updated and properly referenced.

Require new compliance statements for any component substitutions, even when suppliers claim equivalent compliance status, such as:

Any one of these updates triggers documentation review requirements.

Create procedures requiring suppliers to alert you immediately of compliance-impacting changes. Delayed notifications can leave your RoHS declaration out of alignment with actual product composition.

Staying ahead of RoHS compliance requirements is critical as regulations evolve and exemptions expire or are renewed. Understanding high-risk substances, managing supplier data, and planning for potential changes can help ensure your products remain compliant.

Here’s a breakdown of key focus areas and practical strategies to minimize compliance risks.

Several RoHS exemptions are set to expire or face renewal decisions in 2026. Lead-containing solders in specific applications and mercury in certain electronic components represent areas of particular uncertainty.

Monitor European Commission announcements on exemption renewals, as timeline changes can affect your product's compliance status. It’s also helpful to understand how RoHS overlaps with broader chemical regulations, such as REACH, to determine compliance. Build contingency plans for expiries affecting your product portfolio.

Focus compliance attention on historically problematic areas. Surface plating operations often introduce restricted substances, while solder materials may contain lead under specific exemptions.

Pigments in plastic components and PVC cable insulation pose ongoing risks that require careful supplier verification. Ceramic components, particularly in high-temperature applications, may contain restricted substances requiring exemption justification.

Prioritize alternative materials where technically feasible, reducing dependence on exemptions that may expire. Pre-screen new suppliers using standardized compliance questionnaires.

Request updated RoHS declarations from suppliers annually, not just when problems arise. This proactive approach identifies potential issues before they impact your product compliance.

Standardize your RoHS declaration template across product lines to reduce preparation time and ensure consistency. Build a reusable compliance library containing verified supplier statements and test data.

Centralize supplier compliance data in accessible systems, allowing for efficient documentation updates when product configurations change. This systematic approach reduces the administrative burden of maintaining current RoHS compliance letters.

A clear, standardized process is essential for creating accurate and defensible RoHS declarations. When creating your RoHS letter of compliance, consider the following:

Creating a sound RoHS declaration of conformity requires careful planning, thorough evidence gathering, and clear communication with your suppliers. This document is more than just regulatory paperwork; it's a key to unlocking the EU market and a shield for your organization from liability.

By documenting everything, planning for regulatory changes, standardizing your processes, and holding suppliers accountable, you can build a strong foundation for your RoHS compliance strategy and the 2026 requirements.

It seems simple enough. If you’re a manufacturer who uses electronic components to build your products for American or international markets, you...

PCBs are crucial to modern financial systems and play a critical role in the infrastructure that supports the global financial ecosystem. These...

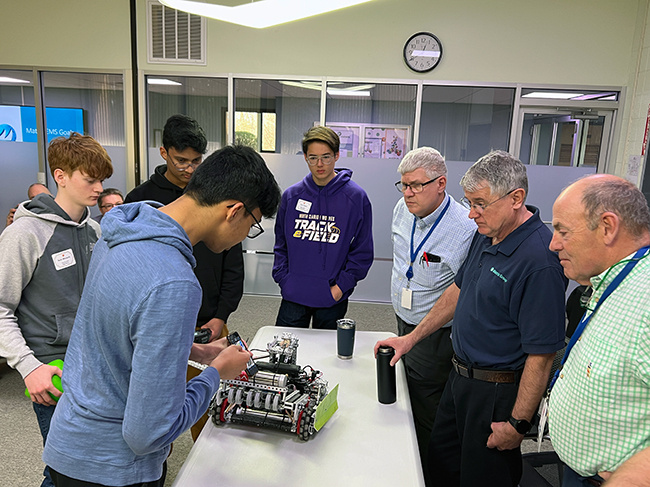

Clarion Jr. Sr. High School Robotics team demonstrates their robot entry for an upcoming competition. A business is not an island. Just as you...