Common Causes of PCB Failure

Printed circuit boards, or PCBs, are essentially the lifeblood of the devices we use every day. Cellphones, TVs, cars, street lights and so many...

When printed circuit boards fail, you can face costly and potentially disastrous consequences. So how do you pick up the pieces afterward?

Understanding the common causes of PCB failure and the tools available to prevent future failures can minimize the stress and cost of dealing with dead PCBs.

Keep reading to find the next steps after PCB failure and how to stop it from happening again.

Three categories cover the reasons for the majority of failures:

PCB design problems include a variety of issues that can occur during design and manufacturing, such as:

Excessive heat, dust, moisture, and electrostatic discharge during assembly are just a few of the environmental factors that can lead to failure.

Stopping age-related failures is a bit more difficult, and it comes down to preventative maintenance more so than repair. However, if a part does fail, instead of tossing out the entire board, it can be more cost-effective to replace old parts with new.

PCBs fail. It’s going to happen. The best strategy is to do everything you can to avoid a repeat.

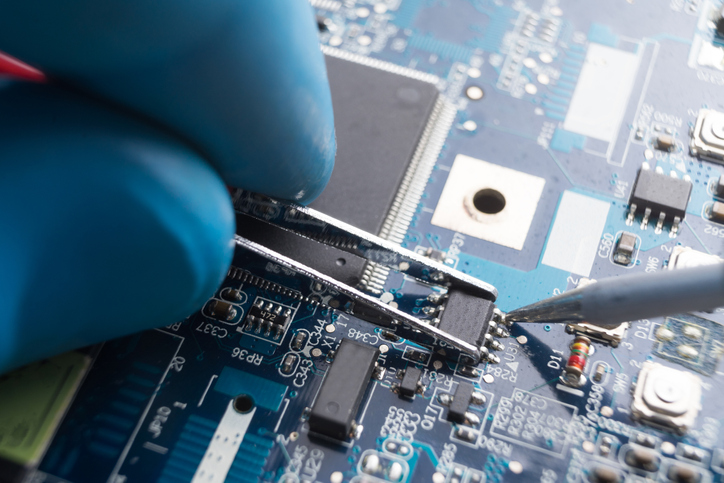

Performing a printed circuit board failure analysis can pinpoint the exact problem with the PCB and helps prevent the same problem from plaguing other current boards or future boards. These tests can be broken up into smaller tests, including:

This method, which involves removing a slice of the board to reveal and isolate components, helps detect issues involving:

Used to locate problems caused by solder mask oxidation and misapplications, this test replicates the solder/material contact to evaluate solder joint reliability. It’s useful for:

This testing approach detects contaminants that can cause wire bond interconnect deterioration, corrosion, metalization, and other problems.

This method uses a powerful microscope to detect soldering and assembly problems.

The process is both accurate and fast. When a more powerful microscope is warranted, the scanning electron microscopy technique fits the bill. It offers up to 120,000X magnification.

This technique provides a non-invasive approach using film, real-time, or 3D X-ray systems. It uncovers current or potential defects, issues involving internal particles, sealing lid voids, substrate integrity, and more.

It’s great to perform a printed circuit board failure analysis and fixing PCB problems so they won’t happen again. Avoiding failures in the first place is even better. There are several ways to avoid failure, including:

Conformal coating is one of the primary ways to protect PCBs from dust, dirt, and moisture. These coatings, which range from acrylic resins to epoxies, can be applied in a variety of ways:

Before an assembly even leaves the manufacturer, it should undergo testing to ensure it won’t fail once it’s a part of a larger piece of equipment. Testing during assembly can take many forms:

Once the product leaves the manufacturer, that’s not always the end of the manufacturer’s services. Many quality electronics contract manufacturers offer aftermarket services to monitor and repair their products, or even products they didn’t originally manufacture. AMS provides assistance in several important areas, including:

Obsolescence management is a segment of AMS that pertains to preventing component incompatibility and age-related failures.

To ensure that your product has the longest life cycle possible, obsolescence management experts make sure high-quality parts are available and in compliance with conflict mineral laws. Achieving these objectives requires the latest software, such as SiliconExpert, with a database of more than 250 million components from thousands of suppliers.

Such a database allows you not only to search for parts, but also find obsolescence forecasts and environmental compliance information. Managing obsolescence keeps you ahead of the curve.

Additionally, consider replacing the circuit cards in your PCBs every X number of years, or X number of returns. Your AMS service will be able to set up a replacements schedule to keep your electronics running smoothly. Better to replace a part than to wait for it to break!

If your PCB fails, you now know what to do next, and what to do to prevent it. However, if you want to minimize risk of PCB failure, you should partner with a quality electronics manufacturer with testing and AMS experience.

Outsourcing your PCB assembly needs can alleviate future issues with component failure and obsolescence.

To learn what Matric is capable of when it comes to managing PCB assembly and aftermarket services, check out our capabilities guide!

Printed circuit boards, or PCBs, are essentially the lifeblood of the devices we use every day. Cellphones, TVs, cars, street lights and so many...

Solder is what makes the electrical connections work on your printed circuit board (PCB). Solderability, then, measures how well metal is wetted by...

Electronics manufacture and testing are like squabbling siblings. PCB testing is a necessary expense that, when done correctly, prevents much larger...